PUREGAS, LLC

P550W2 Series Air Dryers User’s Guide

Page 77 of 99

P012226 – Rev. F

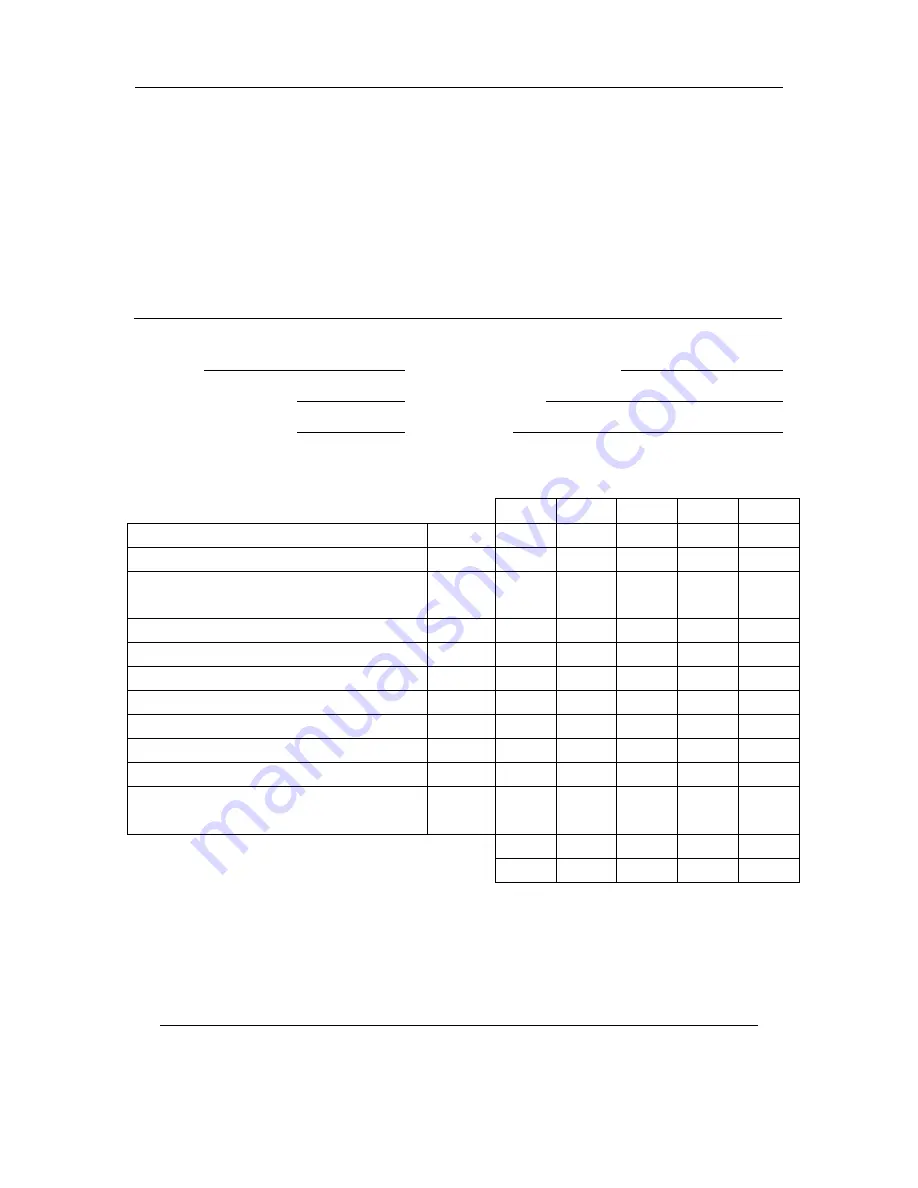

10.3 8,000 Hour Maintenance

Under typical operating conditions:

8,000 hours of run time will occur between one (1) and two (2) years of use.

This will be identified by a

TTL TIME

Alarm on the display.

MODEL:

LOCATION NAME:

SERIAL NUMBER:

ADDRESS:

DATE INSTALLED:

Maintenance Interval (Hours)

Procedure

Section

8,000

16,000

24,000

32,000

40,000

Install 8,000 Hour Maintenance Kit

Read & Record Flow Rate (

FLOW

)

Measure & Record

Compressor Amp Draw

Set System Pressure (345 KPa / 50 PSI)

Set Static Pressure (117 KPa / 17 PSI)

Set Outlet Pressure

Test Consistent Heatless Dryer Cycling

Test Compressor ON/OFF Cycling

Test Air Fittings for Leaks

Reset TTL TIME Reading to Zero

Visually Inspect Inside & Outside of Unit for Loose

Wiring or Hardware

Maintenance Performed by:

Date of Maintenance:

NOTE:

COPY OR PRINT THIS PAGE AND KEEP IT WITH THE AIR DRYER

Summary of Contents for P550W2 Series

Page 2: ......