PUREGAS, LLC

P550W2 Series Air Dryers User’s Guide

Page 92 of 99

P012226 – Rev. F

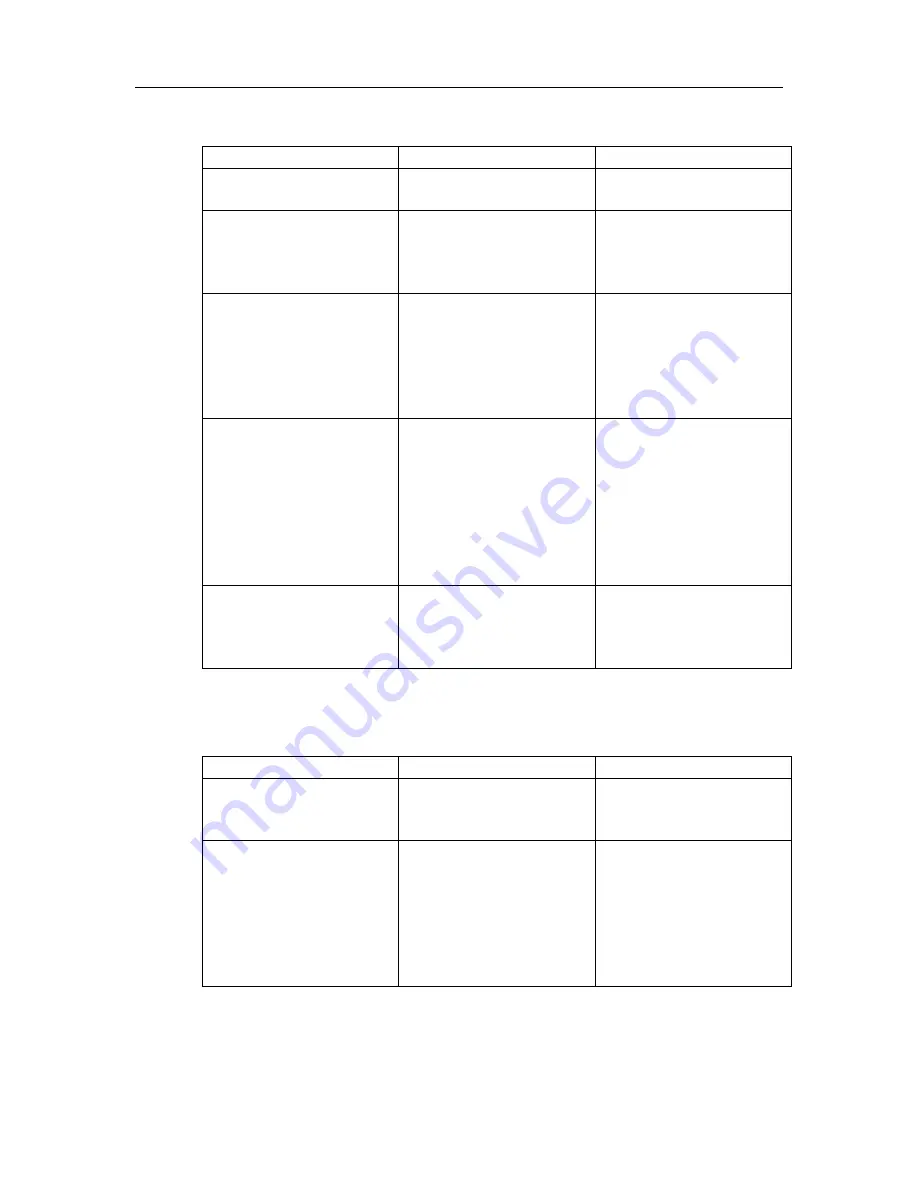

13.17 High Duty Cycle Alarm

Possible Cause

Check

Corrective Action

Low System Pressure

Verify System Pressure

(section 8.9 )

Adjust System Pressure

(section 8.9 )

High Flow condition

Verify Flow Rate

(

FLOW

) reading is not

higher than expected

(section 8.5.5.2 )

Troubleshoot High Flow

condition

(section 13.11 )

Defective Unloader

Valve

Test Unloader Valve

operation (section 9.7 )

If this is continuously

flowing high amounts of

air, the Unloader Valve

is defective.

Replace Unloader Valve

(section 11.3 )

Defective Heatless

Dryer Solenoid Valve

Verify consistent

Heatless Dryer cycling

(section 9.6 )

If either side is

continuously flowing

high amounts of air, the

Solenoid Valve is

defective.

Replace Solenoid

Valves included in the

8,000 Hour Maintenance

Kit (section 11.4 )

Defective control board

Measure voltages at

control board

(section 9.3 )

If measurements are

incorrect, replace

control board (section

11.1 )

13.18

Can’t Create a High Duty Cycle Alarm

Possible Cause

Check

Corrective Action

High Duty Cycle Alarm

set point too high

Verify High Duty Cycle

Alarm set point (section

8.7.5 )

Allow the compressor to

run longer than it is off.

(section 9.11 )

Defective Control Board Verify that the

compressor has run

more than the verified

High Duty Cycle Alarm

set point (above)

Replace Control Board

(section 11.1 ) if the

compressor runs more

than the verified High

Duty Cycle Alarm set

point and fails to create

an alarm.

Summary of Contents for P550W2 Series

Page 2: ......