10

Reverse Osmosis Water Treatment System

Copyright © Puretec Pty Ltd 2020

Step 4: Make Tubing Connections

The connections to the faucet should be complete, the remaining connections are:

•

Feed connection—clear tubing from feed valve to white elbow connector

•

Drain connection—either red tubing from the air gap or black tubing from grey elbow

connector will attach to the drain adapter

•

Permeate connection—blue tubing from faucet to blue elbow connection

•

Attach the fittings to the manifold

A typical connection is shown in Figure 6 Side View and Cutaway of Tubing Fitting.

Note

: For optimal system performance, we recommend using tubing lengths that are as short

as possible.

Post filter

Install the post filter in line with the blue permeate

tubing. Make sure flow direction aligns with water

path. Secure tubing with collet lock clips.

Drain Adapter (Optional)

The drain adapter has a rubber inlet that accepts

the 3/8 inch black drain tube or the 1/2 inch red

tube. The 3/8 inch black tubing will connect here if

the faucet is not using the air gap module.

When the tubing is in position, use the supplied

hose clamps to secure the connection.

Note

: When sliding tubing into the drain adapter

inlet, wet the tubing. Water will help the tubing

slide into the rubber inlet.

Feed Pressure Gauge

The supplied pressure gauge can be connected

to the feed line to monitor system feed pressure.

For proper system performance, the dynamic feed

pressure must be between 275 kPa and 520 kPa

when the system is in operation.

Caution

: The feed pressure gauge is intended for

use only durin installation and troubleshooting

of the RO system. The pressure gauge should be

removed during normal system operation because

some regulatory agencies did not evaluate the RO

system with the feed pressure gauge in place.

Note

: Make sure the tubing is pushed past

the O-rings for a secure fit. Also, when

replacing any tubing, cut tubing back 1/4

inch prior to re-inserting to prevent leaks.

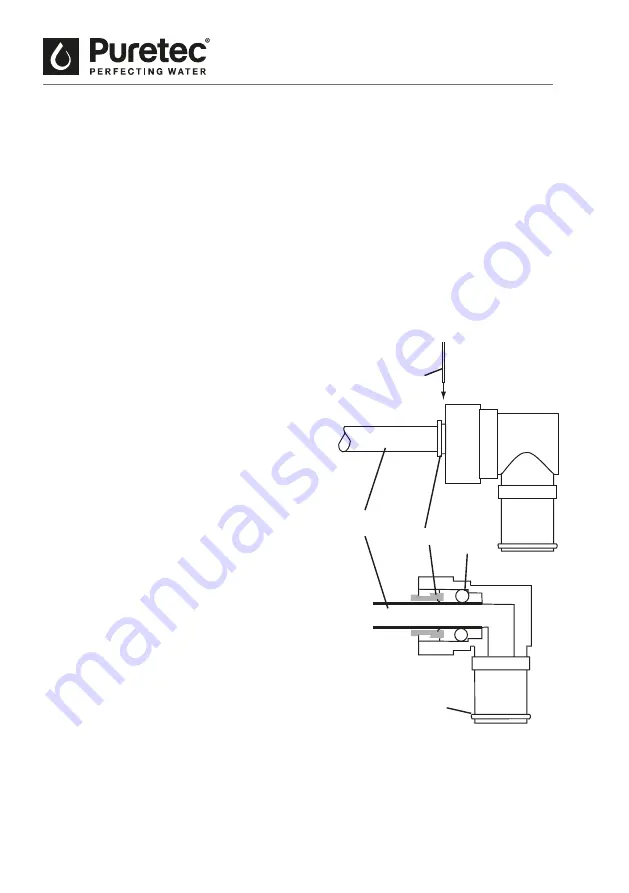

Side View and Cutaway

of Tubing Fitting

Installation Guide

NOTE: Make sure the tubing is pushed past the O-rings for a

secure fit. Also, when replacing any tubing, cut tubing

back ~1/4 inch prior to re-inserting to prevent leaks.

INSTALLATION cont.

Step 4: Make Tubing Connections

The connections to the faucet should be complete, the remaining

Feed connection—clear tubing from feed valve to white elbow

Drain connection—either red tubing from the air gap or black

tubing from grey elbow connector will attach to the drain

Permeate connection—blue tubing from faucet to blue elbow

Attach the fittings to the manifold

A typical connection is shown in Figure 7 Side View and Cutaway of

NOTE: For optimal system performance, we recommend using tubing

lengths that are as short as possible.

Install the postfilter in line with the blue permeate tubing. Make sure

flow direction aligns with water path. Secure tubing with collet lock

Drain Adapter (Optional)

The drain adapter has a rubber inlet that accepts the 3/8-inch black

drain tube or the 1/2-inch red tube. The 3/8-inch black tubing will

connect here if the faucet is not using the air gap module.

When the tubing is in position, use the supplied hose clamps to

secure the connection.

NOTE: When sliding tubing into the drain adapter inlet, wet the

tubing. Water will help the tubing slide into the rubber inlet.

Feed Pressure Gauge

The supplied pressure gauge can be connected to the feed line to

monitor system feed pressure. For proper system performance, the

dynamic feed pressure must be between 40 psi (2.76 bar) and 80 psi

(5.52 bar) when the system is in operation.

The feed pressure gauge is intended for use only during

O-Ring

O-Ring

Collet

Tubing

Collet

Lock Clip

Figure 7 Side View and Cutaway of Tubing Fitting

Fig. 6