- 12 -

www.purex.co.uk

purex@purex.co.uk

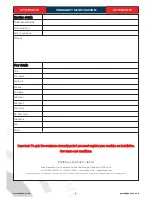

TROUBLESHOOTING

Notes:

Warning status

- is an audible chime every 20 seconds and the keypad flashing (red) every 10 seconds.

This stage allows the operator time to identify the problem and take appropriate action e.g. acquire a

replacement filter.

Alarm status

- is an audible chime and the keypad flashing (red) every 1 second. At this point the

problem should be identified and remedial action taken immediately.

Filters

- Some machines use a single combined HEPA / Chemical filter while others employ separate

HEPA and chemical filters. Therefore the machine icons may vary depending on the type of machine

you have.

22

0

0

°

C

m

3

/ hr

A nozzle or connecting hose/pipe may have a leak / blockage or the

vacuum sensor tubes (if fitted) in the air inlet may be blocked.

Check all nozzles, hose/pipe connections and the vacuum sensor tube

(if fitted) for leaks / blockages.

The pre-filter may be blocked.

or...

The HEPA/Chemical filter (or separate HEPA filter if appropriate)

may be blocked.

Change the pre-filter.

or...

If the pre-filter has been changed quite recently then change the main

HEPA/Chemical filter (or separate HEPA filter if appropriate).

The HEPA/Chemical filter (or separate chemical filter if appropriate)

is missing, not fitted correctly or is damaged.

Check the HEPA/Chemical filter (or separate chemical filter if

appropriate) is fitted correctly in the machine, is locked into position

correctly and is undamaged.

The HEPA/Chemical filter (or separate chemical filter if appropriate)

may be exhausted.

Replace the HEPA/Chemical filter (or separate chemical filter if

appropriate)

The exhaust monitor unit inside the machine may have developed a

fault.

This is a sealed unit. Contact your supplier for a replacement exhaust

monitor unit.

The HEPA/Chemical filter (or separate HEPA filter if appropriate) is

missing, not fitted correctly or is damaged.

Check the HEPA/Chemical filter (or separate HEPA filter if

appropriate) is fitted correctly in the machine, is locked into position

correctly and is undamaged.

The combined HEPA/Chemical filter (or separate HEPA filter if

appropriate) may be exhausted.

Replace the HEPA/Chemical filter (or separate HEPA filter if

appropriate)

The exhaust monitor unit inside the machine may have developed a

fault.

This is a sealed unit. Contact your supplier for a replacement exhaust

monitor unit.

The alarm has triggered and the blower stops.

The thermal cutout on the blower may have engaged. Check the

cooling vents both inside and out. Switch off mains power and allow

the blower to cool. If this does not remedy the fault please contact

your supplier.

Blower does not function

Power supply to blower absent or incorrect. Check all cables and

connections and ensure the power supply matches the requirements of

the machine.

Control signal to/from interfaced equipment is incorrect or absent. Check all cables and connections are correct.

The blower inside the machine may have developed a fault.

Check all cables and connections first. Then contact your supplier.

The control PCB inside the machine may have developed a fault.

Check all cables and connections first. Then contact your supplier.