2.

Introduction

4

During the treatment process the water gets through the mul-

tiway valve by the entrance connection, flows to the upper part

of the softener through the distributor producing this way an

ionic exchange inside the resin bed.

The treated water is collected by the distributor and driven

through the inner tube through the vessel till the multiway val-

ve. It is sent with the out connection till the main water pipe for

consumption. In this point the system has a counter for treated

water to be contabilized.

2.3 Regeneration of the system

The quantity of the calciun and magnesium ions that the resin

can keep is limited so the volume of water that a softener can

treat is also limited. Because of this the system has to do from

time to time a process known by regeneration that allows the

resin to be charged again with sodium ions in order to be able

to make the softening process again.

In Denver systems the regeneration process starts automati-

cally when the systems detects that the exchange capacity is

going to finish, the timer incorporated in the system allows to

configurate in a different way the starting of the regeneration,

please see section 6.3 in order to get more information about

how the programme works.

The regeneration of a softener system is made of different

parts, each with a concrete finality

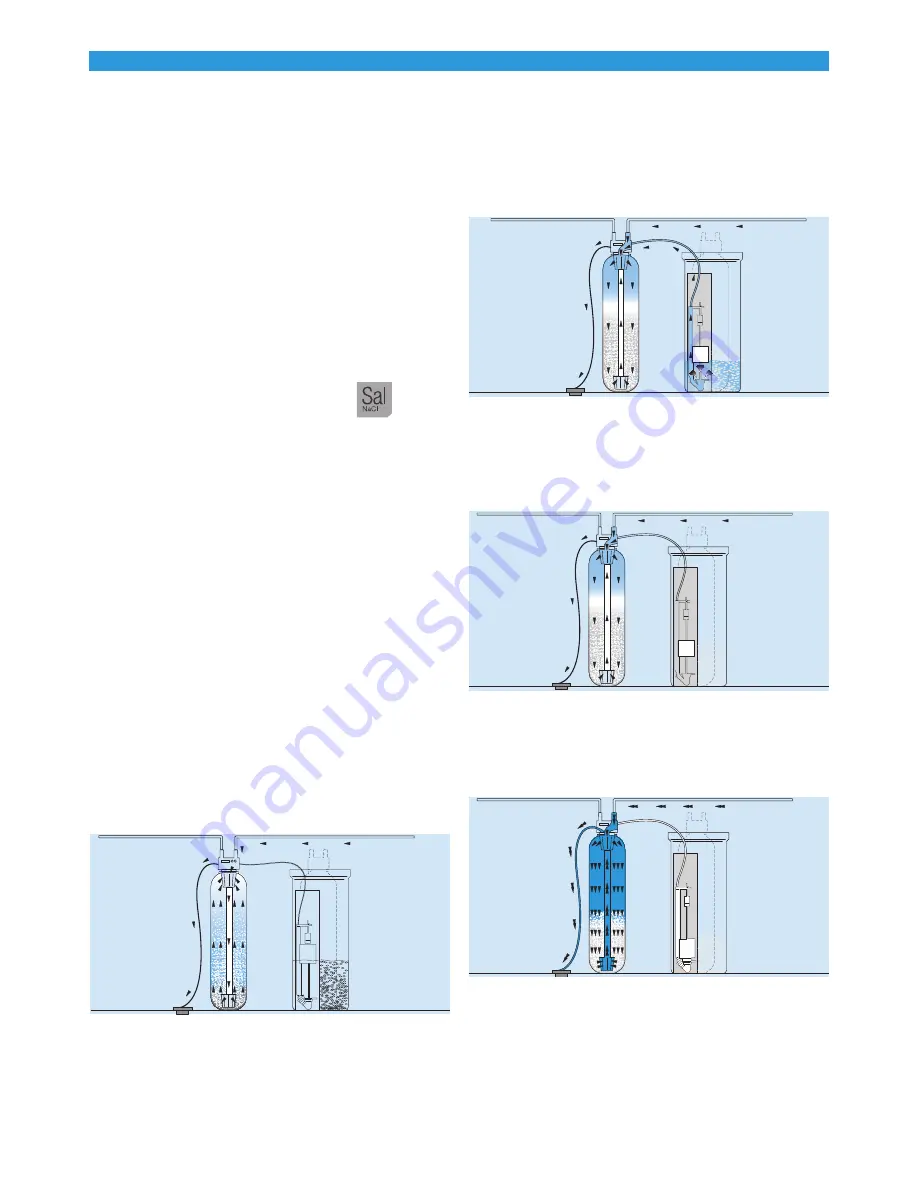

BACKWASHING:

The water gets into the vessel through an inferior collector,

making a washing and a floffing of the resin bed and

allowing, this way, the following regeneration process.

ASPIRATION OF BRINE:

Through an aspiration process for venturi effect the system

suctions the brine liquid solution previously prepared for the

regenerating tank. This salt solution is introduced into the sof-

tening vessel getting in contact with the ionic exchange resin

and starting the regeneration.

SLOW RINSE:

It refers to the movement in the resin bed of the salt solution

previosly aspirated, this way the contact of the salt with the

resin is higher and the regeneration of the same is optimized.

FAST RINSE:

The water flows through the resin bed making a final wash of

the same and ensuring the total removing of the salt that can

be inside the vessel.

LLENADO DEL DEPÓSITO:

The volume of water goes automatically to the brine tank in

order to prepare the necessary brine to be consumed in the

next regeneration.This process is automatic, so normally it is

not necessary to put more water in the brine tank (except du-

ring the starting up as shown in section 7.

Water inlet

Conditioned water

To the drain

To the drain

Brine aspiration.

Venturi effect

Water inlet

Conditioned water

To the drain

Brine aspiration.

Venturi effect

Water inlet

Conditioned water

To the drain

Water inlet

Conditioned water