22

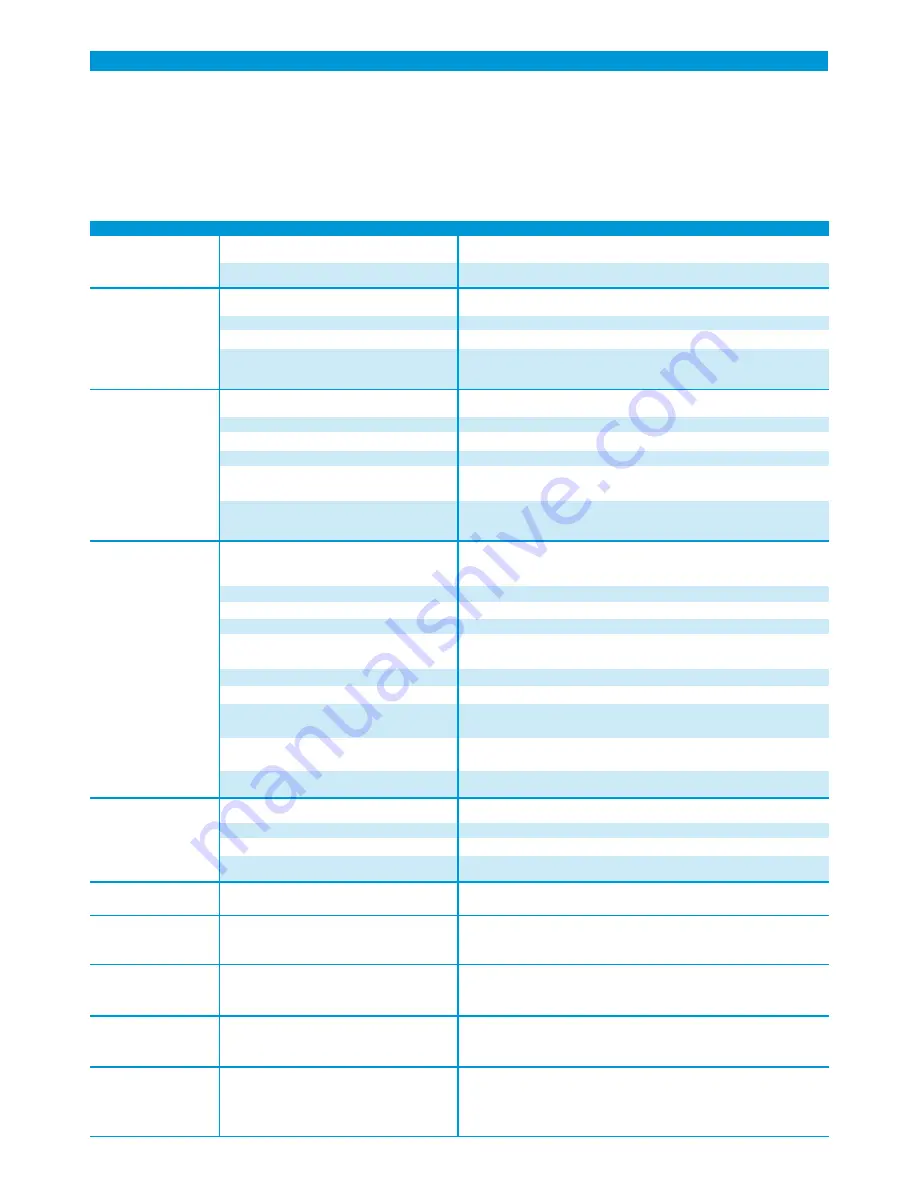

9. IDENTIFICATION GUIDE AND PROBLEM RESOLUTION

SYMPTOM

1. Leak from tap.

2. Exterior leak to the

system in sink

cupboard.

3. No production.

4. Little production.

5. Excessive production.

6. High T.D.S.

7. Metallic, bitter or

acidic taste.

8. Plastic or synthetic

taste.

9. Unpleaseant taste

or smell.

10. Colour of water is

whitish.

CAUSE

Turn off components worn.

Joint pinched or worn.

By base of tap.

In drain.

In feed.

In feed tubes of the system.

There is no water supply.

Electro in-let valve closed.

Pre-filter blocked.

Membrane is saturated.

Valve cleaned /restrictors.

There is no electricity supply.

Low pressure in the membrane feed.

In-let valve partially closed.

Tank valve closed.

Air tank empty.

Water tank has a hole/s.

Pre-filter very dirty.

Membrane with tip of joint pinched.

Membrane very obstructed.

Pump in very bad condition.

Excessive rejection.

Membrane housing in bad condition.

Membrane housing empty.

Nut joints in bad condition.

Connection of piping not carried out properly.

Membrane housing in bad condition.

Water has low pH.

Post-filter saturated.

Contamination.

Air in the system.

9. Identification guide and problem resolution

SOLUTION

Substitution of tap.

Change joints.

Check condition of tap and if necessary substitute it.

Tighten or replace.

Check to see if there is sufficient teflon in the in-let valve or substitute it.

They are tightened too close to the wall. Do not have holding pins. They are

in bad condition. (substitute them) or not pushed into connectors enough.

Wait until supply returns.

Check condition of coil and clean it. Change it, if necessary.

Change filter.

Change membrane. Check condition of restrictor.

If blocked, clean or substitute.

Clean or substitute.

Check supply in the house. Check the tension at the exit of the transformer.

(if there isn’t any, change it).

Check system pressure, and where necessary put in pump and minimum

pressure switch.

Open it.

Open it.

Check tank pressure and if necessary pressurise up to 7 PSI.

Check if water is coming out of the air valve.

Substitution of the same.

Look at flow of the post-filter outlet and if this is the case, substitute it.

If pinched, substitute the membrane.

Check production flow.

If there is very little, and pressure is good, substitute it.

Check that the pump generates between 6 and 7 Kg. /cm

2

at the entrance

of the membrane carrier. If this is not the case, substitute the head.

Check the flow of the restrictor, and if necessary substitute it.

Rejection and production may be connected. Substitute it.

Put in membrane.

Production and rejection connected. Substitute joints or membrane

Check system flow.

Production and rejection connected. Substitute membrane and/or joints.

Put in re-mineralising post-filter before closing.

Change post-filter.

Change filters, membrane and hygienisation.

Wait. There is no problem.

Summary of Contents for PROLINE PLUS

Page 1: ...INSTRUCTIONS MANUAL PROLINE PLUS PROLINE PLUS PUMP ...

Page 3: ...3 ...

Page 27: ...27 ...