26

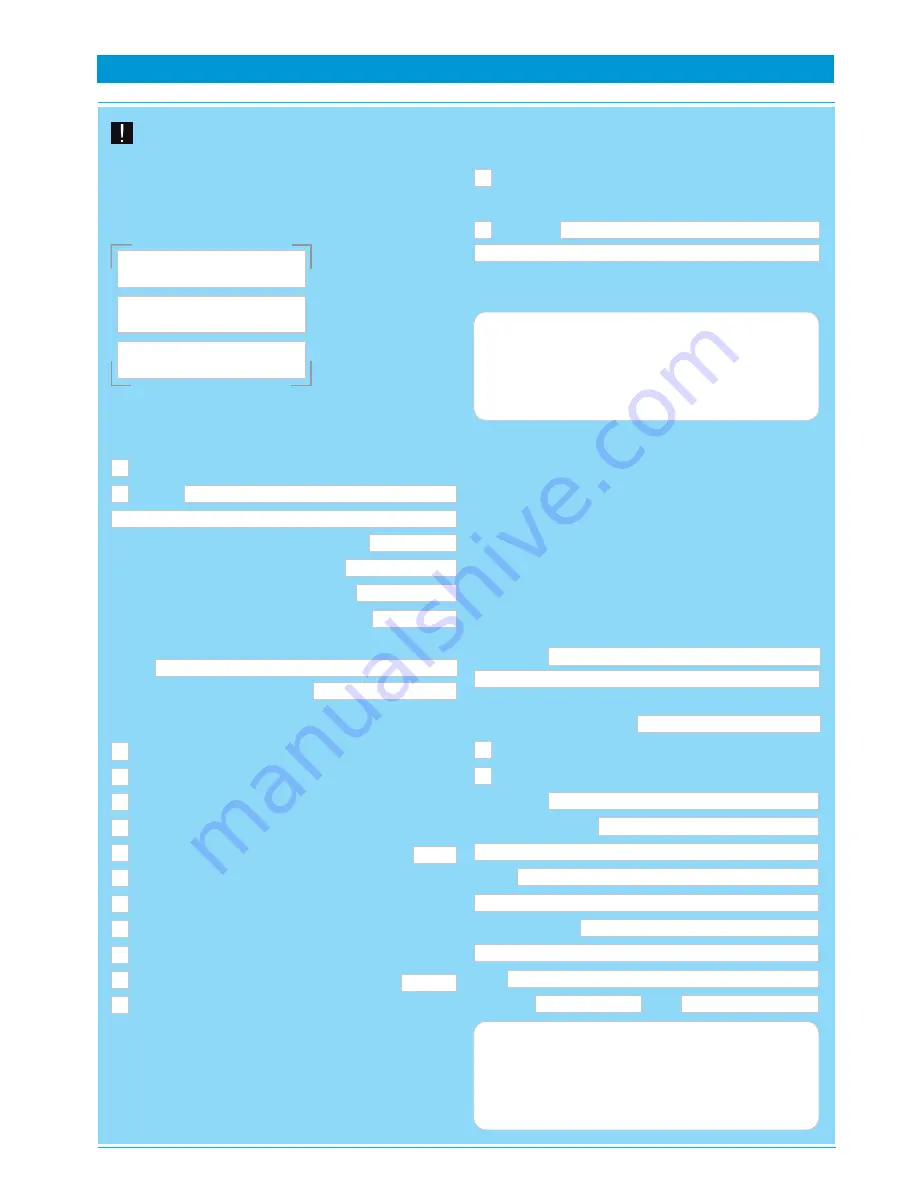

SHEET REGISTERING THE INSTALLATION AND PUTTING INTO OPERATION OF THE EQUIPMENT

SHEET TO BE COMPLETED BY THE TECHNICIAN INSTALLER.SHEET FOR THE TECHNICIAN INSTALLER.

Adhesive label

for identification

of system installed

COMMENTS

*Results of installation and putting into operation.

CORRECT (system installed and working properly.

Water produced adequate for the application)

OTHERS

IDENTIFICATION OF AUTHORISED TECHNICIAL/INSTALLER:

Company and/or installer, date and signature:

ACCEPTANCE OF THE OWNER OF THE SYSTEM:

I have been informed clearly of the use, manipulation and

maintenance that the system installed requires, having

been offered a maintenance contract and informed of

how to contact Customer Services, should I need to ask

for information, or to report a breakdown or that the

system is not working properly, request maintenance or a

technician.

Comments

* Ref. Maintenance contract

ACCEPT the maintenance contract

DO NOT ACCEPT the maintenance contract

Model/Ref.:

Owner Mr/Miss/Mrs

Street:

Telephone No.s:

City:

Province: P.C.:

Date and signature

:

NOTES FOR THE TECHNICIAN/INSTALLER:

Read the present manual carefully. Should you

have any doubts, please contact your distributor’s technical attention service (T.A.S.).

The information marked (

*

) must be completed by the technician installer and he/she must copy them

him/herself to the GUARANTEE CERTIFICATE SHEET.

The installer/distributor must keep this sheet and Ionfilter may request it, with the objective of

improving the post-sales service and customer service to the client.

The technician carrying out the installation and putting the equipment into operation must have the

appropriate technical capacity.

S/O

P/N

S/N

INFORMATION CONCERNING THE APPLICATION OF

THE EQUIPMENT:

Origin of the water to be treated:

Public network supply.

Others:

*Previous treatment of the RO equipment:

*Feed hardness of equipment RO [ºF]:

*TDS hardness of equipment RO [ppm]:

*Feed pressure of the equipment RO [bar]:

Chlorine concentration in the feed of the equipment RO

[ppm]:

pH in the feed of the equipment:

CONTROL OF THE INSTALLATION STEPS:

Washing of carbon pre-filters.

Washing of carbon post-filters.

Membrane assembly.

Hygienisation according to described protocol.

Concentration of chlorine in tap after flushing:

Checking of flow restrictor.

High pressure switch setting.

Revision and couplings.

Watertightness of pressurised system.

*TDS water produced (work top tap) [ppm]:

Provide clear information about the proper use, mani-

pulation and maintenance of the equipment in order to

guarantee the proper working of the same and the quality

of the water produced. Given the importance of the

proper maintenance of the equipment in order to guaran-

tee the quality of the water produced, the owner must be

offered a contract for maintenance to be executed by

technicians with the capacity to do so.

Summary of Contents for PROLINE PLUS

Page 1: ...INSTRUCTIONS MANUAL PROLINE PLUS PROLINE PLUS PUMP ...

Page 3: ...3 ...

Page 27: ...27 ...