Fuel System

3-1

Section 3

OS 385

Fuel Systems

3.1 General

The fuel system of your Pursuit boat is

designed to meet the requirements of the

U.S. Coast Guard, National Marine Manu-

facturers Association (NMMA), and Ameri-

can Boat and Yacht Council (ABYC) in effect

at the time of manufacture.

The fuel system was factory inspected and

pressure tested in accordance with regula-

tions in effect at the time of manufacture. It is

the responsibility of the boat owner to main-

tain the safe condition of the system.

Inspect

the system frequently to ensure no deterio-

ration or loosening of connections has

occurred.

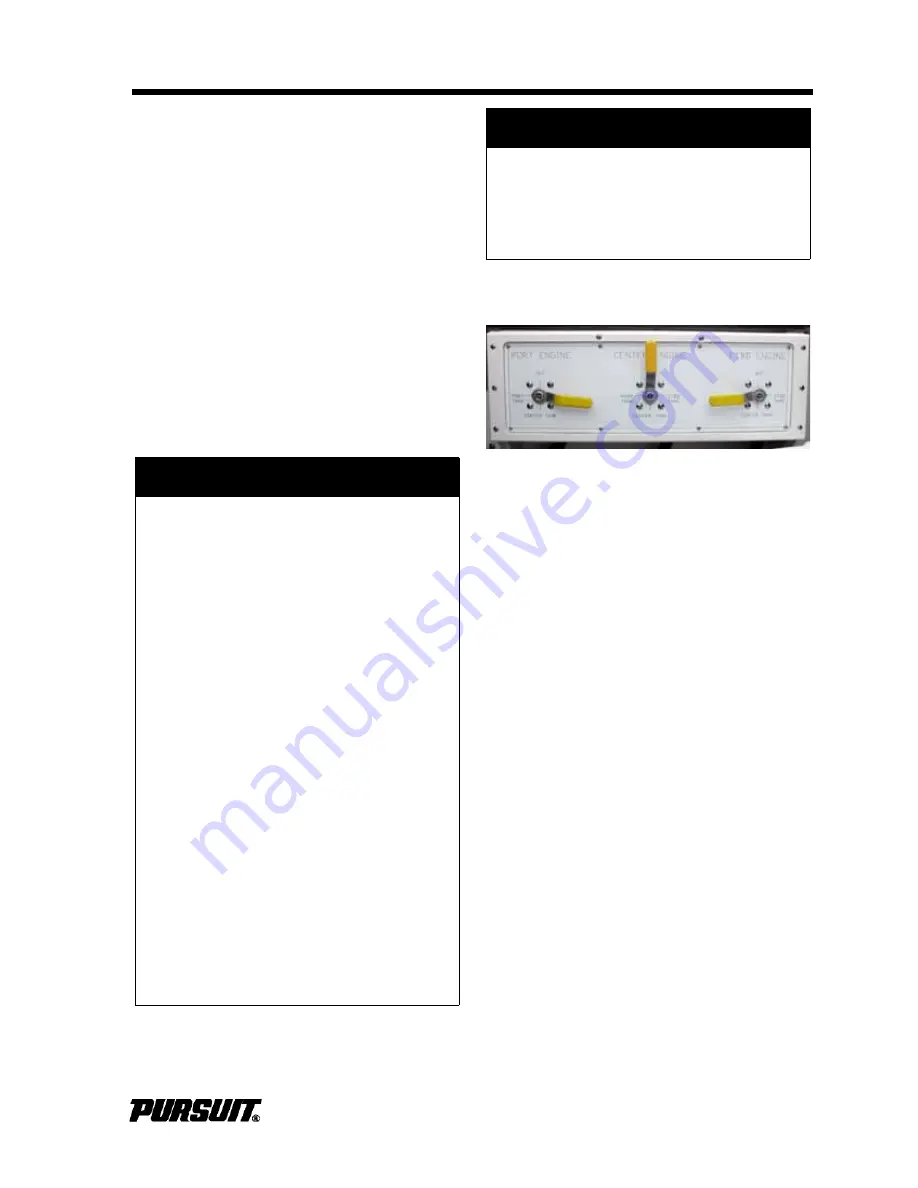

3.2 Fuel System

The outboard fuel system on your Pursuit

has three fuel tanks and a fuel management

system. The fuel manifold is located in the

mechanical space under the hatch in the

cockpit floor. Fuel flow to the engines is con-

trolled by three four-way valves depending

on engine configuration. The selected tank

is indicated by the position of the point on

the selector valve handle.

During normal operation, each engine

should be running off of its respective tank

(refer to the photo). The valves should be

set so that each engine draws fuel from its

respective tank. If a fuel supply problem

should occur in one of the fuel tanks, any

combination of engines can be temporarily

operated from any tank by opening valves

from that tank. Operating the boat with all

fuel valves open to the starboard or port tank

should be avoided.

!

DANGER

FIRE/EXPLOSION HAZARD

Fuel and their vapors are highly explo-

sive when exposed to open flame or

spark, resulting in death or serious

injury.

•

Make sure no vapors are present

before turning on electrical equip-

ment or starting engines.

•

Make sure fuel is added to the fuel

tank only. DO NOT confuse other

deck fills with fuel fills.

•

DO NOT remove anti-siphon

valves from the system.

•

Turn off all electrical switches

before servicing the fuel system.

•

DO NOT drain any fuel in the bilge.

•

Check all fuel lines and fittings for

leaks before and after starting the

engines and after any fuel system

service.

•

Prime fuel system and check all fit-

tings for leaks before and after

starting the engines.

•

DO NOT block fuel vents.

•

DO NOT store fuel in any contain-

ers or compartments not desig-

nated for fuel storage.

!

NOTICE

Certain bulkhead areas are sealed fol-

lowing U.S. Coast Guard regulations

at the date of manufacture. Any modi-

fications must be in accordance with

the regulations.

Fuel Management System

Summary of Contents for OS 345

Page 2: ......

Page 4: ...Operator Notes OS 375...

Page 16: ...12 Operator Notes OS 385...

Page 32: ...3 6 Operator Notes OS 385...

Page 34: ...4 2 Section 4 Electrical System OS 385 Main Distribution Panel MDP...

Page 54: ...5 8 Operator Notes OS 385...

Page 56: ...6 2 Operator Notes OS 385...

Page 98: ...12 6 Operator Notes OS 385...

Page 104: ...A 6 Operator Notes OS 385...

Page 106: ...B 2 Appendix B Maintenance Log OS 385 Date Hours Dealer Service Repairs Maintenance Log...

Page 107: ...Maintenance Log B 3 Appendix B OS 385 Date Hours Dealer Service Repairs...

Page 108: ...B 4 Appendix B Maintenance Log OS 385 Date Hours Dealer Service Repairs...

Page 109: ...Boating Accident Report C 1 Appendix C OS 385 Boating Accident Report...

Page 110: ...C 2 Appendix C Boating Accident Report OS 385...

Page 111: ...Float Plan D 1 Appendix D OS 385 Float Plan...

Page 112: ...D 2 Operator Notes OS 385...

Page 116: ...E 4 Operator Notes OS 385...

Page 117: ...Schematics F 1 Appendix F OS 385 Schematics...

Page 118: ...F 2 Appendix F Schematics OS 385...

Page 119: ...Schematics F 3 Appendix F OS 385...

Page 120: ...F 4 Appendix F Schematics OS 385...

Page 121: ...Schematics F 5 Appendix F OS 385...

Page 122: ...F 6 Appendix F Schematics OS 385...

Page 123: ...Schematics F 7 Appendix F OS 385...

Page 124: ...F 8 Appendix F Schematics OS 385...

Page 125: ...Schematics F 9 Appendix F OS 385...

Page 126: ...F 10 Appendix F Schematics OS 385...

Page 127: ...Schematics F 11 Appendix F OS 385...

Page 128: ...F 12 Appendix F Schematics OS 385...

Page 129: ...Schematics F 13 Appendix F OS 385...

Page 130: ...F 14 Appendix F Schematics OS 385...

Page 131: ...Schematics F 15 Appendix F OS 385...

Page 132: ...F 16 Appendix F Schematics OS 385...

Page 133: ...Schematics F 17 Appendix F OS 385...

Page 134: ...F 18 Appendix F Schematics OS 385...

Page 135: ...Schematics F 19 Appendix F OS 385...

Page 136: ...F 20 Appendix F Schematics OS 385...

Page 137: ...Schematics F 21 Appendix F OS 385...

Page 138: ...F 22 Appendix F Schematics OS 385...

Page 139: ...Schematics F 23 Appendix F OS 385...

Page 140: ...F 24 Appendix F Schematics OS 385...

Page 141: ...Schematics F 25 Appendix F OS 385...

Page 142: ...F 26 Operator Notes OS 385...

Page 143: ......

Page 144: ......