105

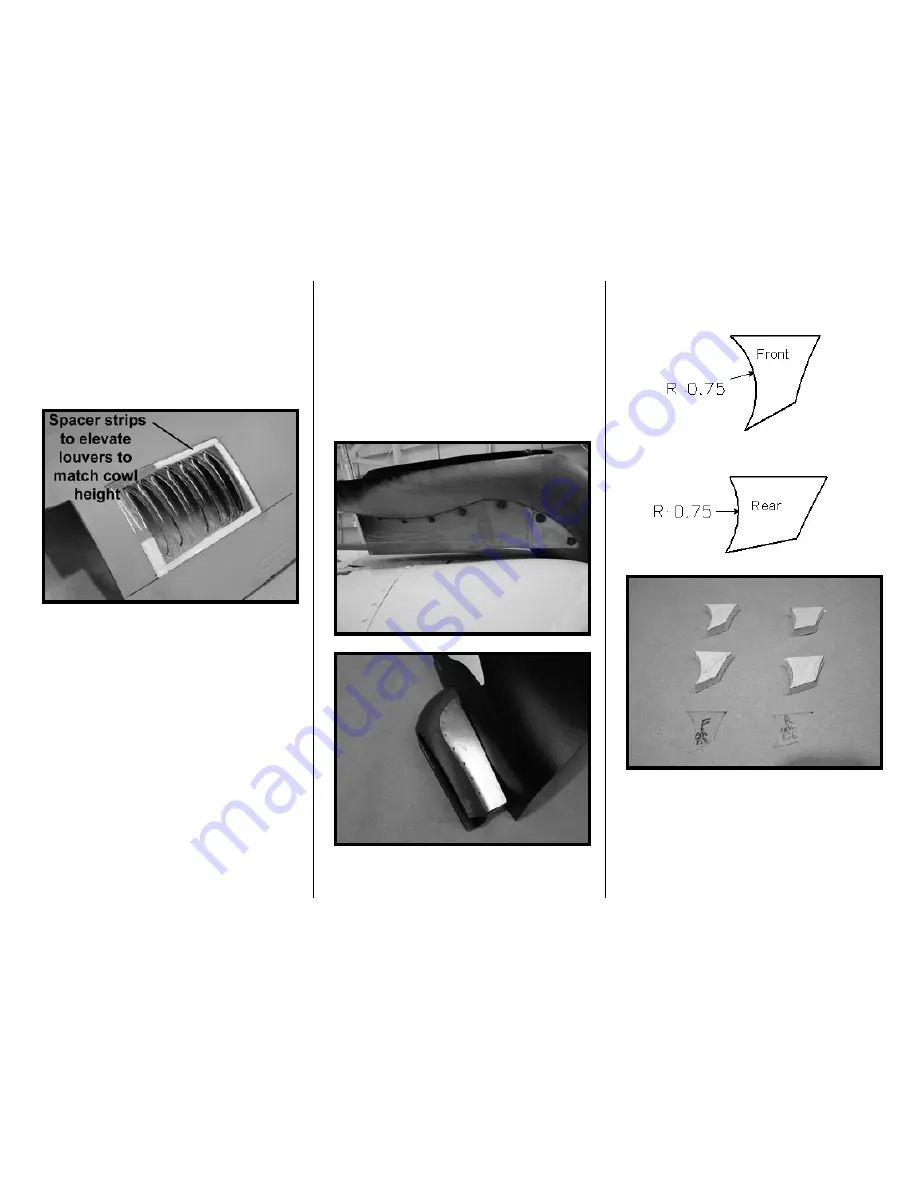

cowl, so you may need to CA in some

plastic strip spacers to elevate the

louver to match the outer surface of the

cowl.

8. Once the surfaces are even, CA in

the louver.

Exhaust Stacks:

For a sturdy mount, you will be securing

the exhaust stacks to the upper cowl.

We encourage you to use one of these

stacks as your muffler’s exhaust outlet,

but there are some considerations. The

supplied stacks are molded PVC so you

will need to shield the critical portions of

the stack from the exhaust heat. We

have found thin pieces of G-10 screwed

to the inside of the stack works well.

Alternatively, you can get a metal

exhaust stack at a hardware store – look

for a 1.5” dia. “wall tube” in the plumbing

section. You can also purchase an

optional, pre-cut metal exhaust stack

from us for $12 each.

There are a few critical alignments to

make before you bolt it on. To give you

an idea of what you’re re-creating, here

is a picture of the full-size stack from the

bottom and our prototype model’s left

exhaust stack.

1. Begin by making the support ribs

from ¼” scrap balsa (two per side).

Tracing the outlines below onto a clear

plastic template helps this task.

The ribs are slightly oversized to allow

for final adjustments. The alignments

for the stacks are as follows.

Rear Edge: Needs to be 1 1/8” from the

cowl.

Summary of Contents for T-34C TURBO MENTOR

Page 190: ...191 This Page Intentionally Left Blank ...

Page 191: ...192 Fin Rudder Template ...

Page 192: ...193 This Page Intentionally Left Blank ...

Page 193: ...194 ...

Page 194: ...195 This Page Intentionally Left Blank ...

Page 195: ...196 Laser Cut Parts Diagram ...