149

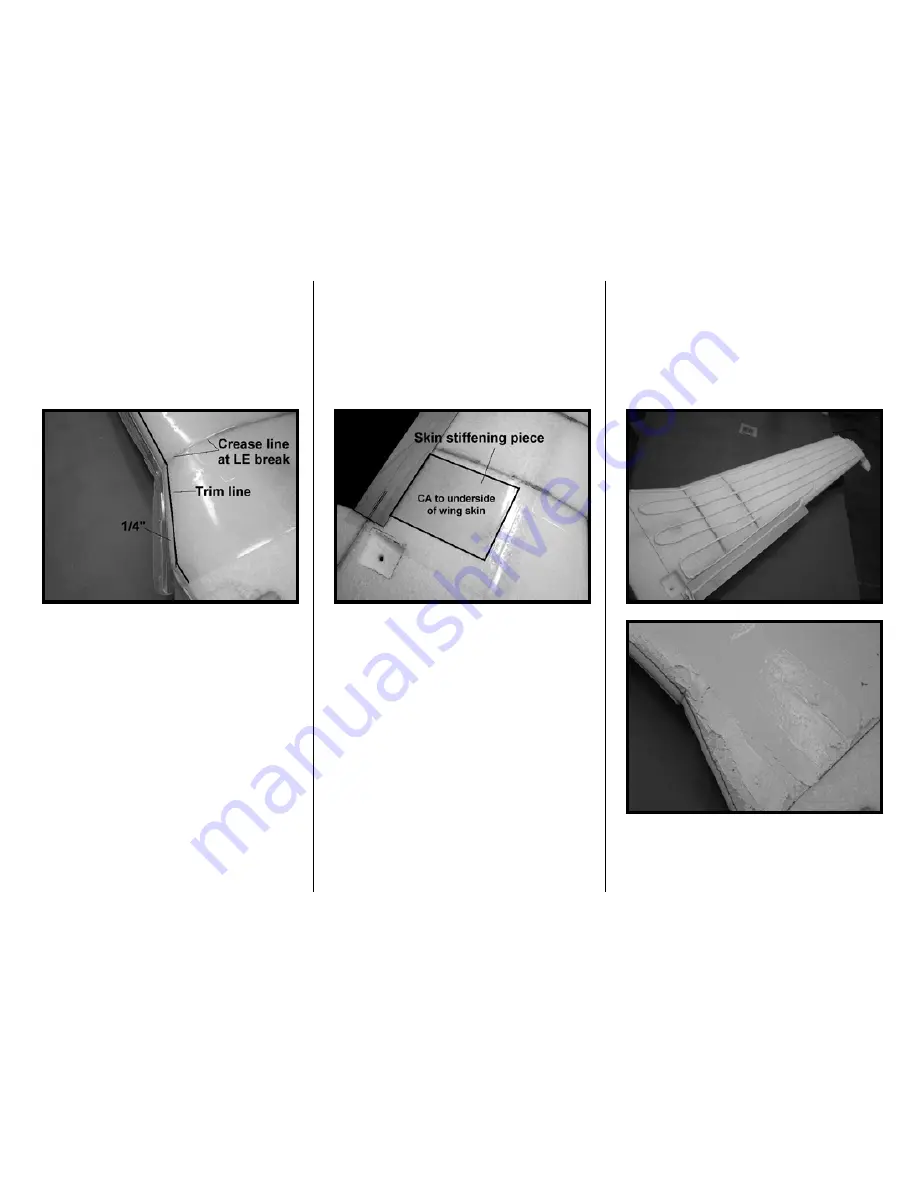

The root should be cut to maximize the

usable material (just remove the

flashing). The LE should be cut back ¼”

from the wing’s LE. Position the skin in

place and trace its edge at the root, LE

and tip so you know where to spread the

adhesive.

6. There is an area on the top wing skin

that usually produces a surface wave

that is larger than desired. This area is

near the root’s TE and best defined as

the scale walkway area behind the

molded spar detail and forward of the

ply TE support. This area is devoid of

molded detail, and thus susceptible to

waves. To offset this, cut a piece of

.010” or.020” scrap polycarbonate the

size roughly shown below and mark its

outline on the wing. This will become a

skin stiffening piece.

Remove the film from the underside of

the wing skin and all film from the scrap

piece. Sand each area where the

pieces will make contact. Apply ample

CA to the piece and position onto the

underside of the wing skin. Press the

piece firmly on a flat surface while the

CA cures. This will firm up the area and

minimize the likelihood of surface

waves.

7. The top wing skin will require a small

extension at its tip end. First, trim the tip

skin (near where you rough trimmed it)

with a straight edge. Cut a piece of

scrap .010” polycarbonate as long as

the tip skin (cordwise) and about 2” wide

– cut its mating edge with a straight

edge too. Make a joiner strip from scrap

polycarbonate as long as the tip and

about ¾” wide. Remove the film from

the extension and joiner pieces. Sand

the mating areas of all skins. Butt the

extension piece next to the wing tip with

the bottom side up. Apply CA to the

edges of the joiner strip and position it

across the joint.

8. Apply adhesive as shown below.

The top of the wing will be exposed to

significant heat from the sun so you

want to have sufficient adhesive. After

spreading the adhesive even over the

wing you may still have a need to apply

more adhesive for sufficient coverage.

Summary of Contents for T-34C TURBO MENTOR

Page 190: ...191 This Page Intentionally Left Blank ...

Page 191: ...192 Fin Rudder Template ...

Page 192: ...193 This Page Intentionally Left Blank ...

Page 193: ...194 ...

Page 194: ...195 This Page Intentionally Left Blank ...

Page 195: ...196 Laser Cut Parts Diagram ...