Installation Guide / PostMount 3-A for XL Panels

5

Code-Compliant Planning and Installation Guide V 1.1 - Complying with AS/NZS1170.2-2011 ADMT 4-2016

- System Overview -

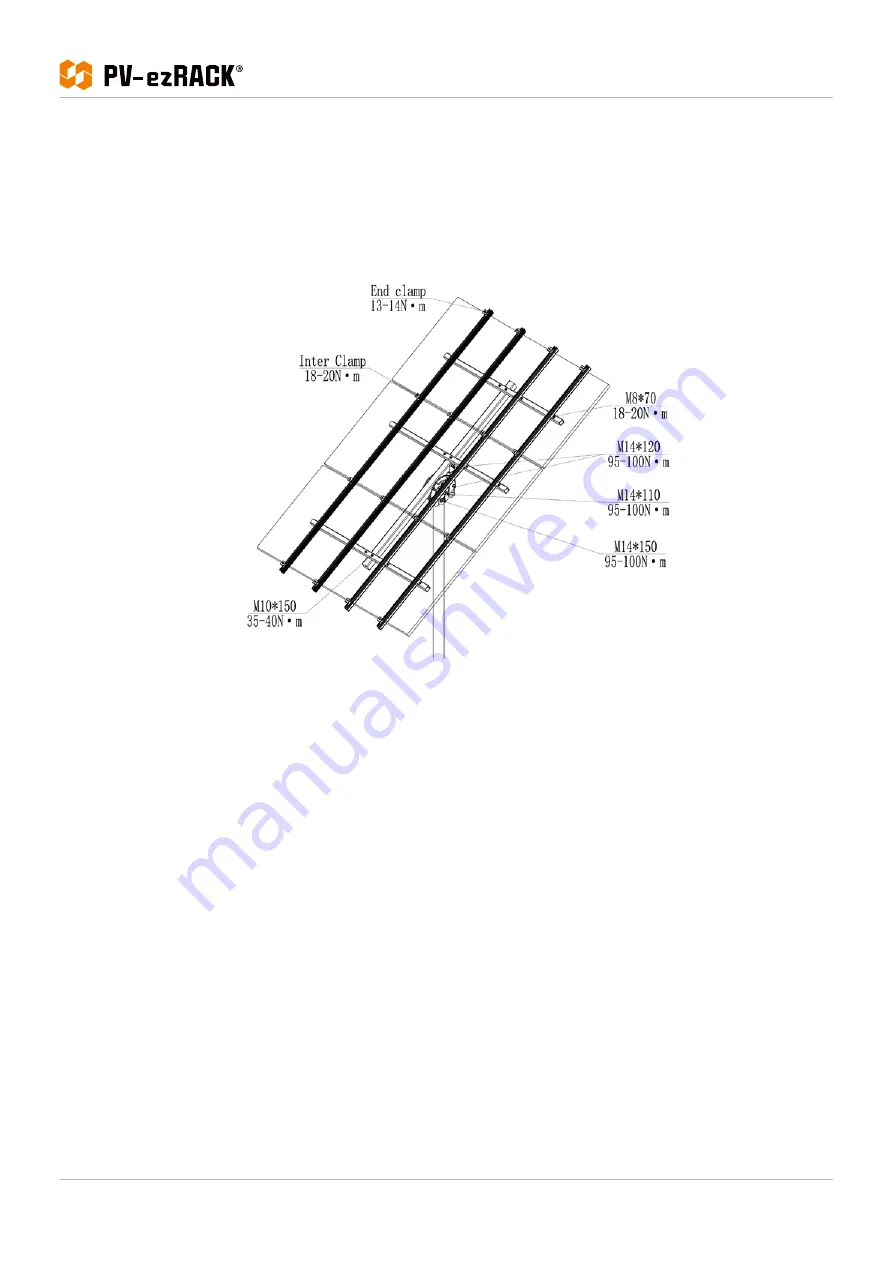

Safe Torques

Please refer to safe torques defined in this guide as shown in the figure below. If power tools are required, Clenergy

recommends the use of low speed only. High speed and impact drivers increase the risk of bolt galling (deadlock). If

deadlock occurs and you need to cut fasteners, please make sure that there is no load on the fastener before you cut it.

Avoid damaging the anodized or galvanized surfaces.

All drawings and dimensions in this installation guide are for generic reference. The PV-ezRack® PostMount 3-A for

XL Panels is to be optimized to suit specific conditions for each project and documented in engineering drawings. As

a result, major components of the PV-ezRack® PostMount 3-A for XL Panels may be provided in sectional sizes and

lengths that vary from those shown in this guide. The installation operations detailed in this instruction guide remain

the same regardless of the component size. In case you need to do any on-site modifications or alteration of the

system in a way that would be different from engineering drawings, please provide marked up drawings/sketches

forClenergy’s review prior to modification for comment and approval.

3. Installation Dimensions