Operation and Maintenance Manual Rev M(ii) 4/03

- 22 -

volume was outside acceptable parameters, the flow error screen appears. This screen is similar to the flow

data screen shown above. The board should be removed before returning the machine to operation.

NOTE: Any changes made to settings in the material delivery system (material pressure, stroke

adjustment, etc.) may affect the data from the flow monitor. If this happens, the operator may need to

determine the correct material volume again.

Flow Monitor Calibration

Periodically, the flow monitor calibration should be checked. Start by connecting a PC to the Dispensing

System, open a terminal screen and enter DEZ=0. This resets the flow monitor encoder to zero. Then

dispense 10 cubic centimeters of material through any valve, by means of a manual purge. When finished,

enter MG _DEZ on the terminal screen. This returns a value representing the number of encoder counts

read by the flow monitor. Calculate the flow monitor calibration value: (Encoder Counts / 10) = FC_CAL.

Change the value of the FC_CAL variable in the Machine-Specific Information section of the

Main

program to the result of the calculation.

NOTE: For a more precise calibration, determine volume by weight. The specific gravity or density of

the material must be known to do this.

Flow Control Mode

Flow control mode is typically accessed through the Cycle Stop menu using the F2 function key. If access

to Flow Control mode is not achieved through Cycle Stop, or if more than one flow monitor is installed on

the workcell, documentation in the Optional Equipment section of the Operator’s Guide will provide details

on these options.

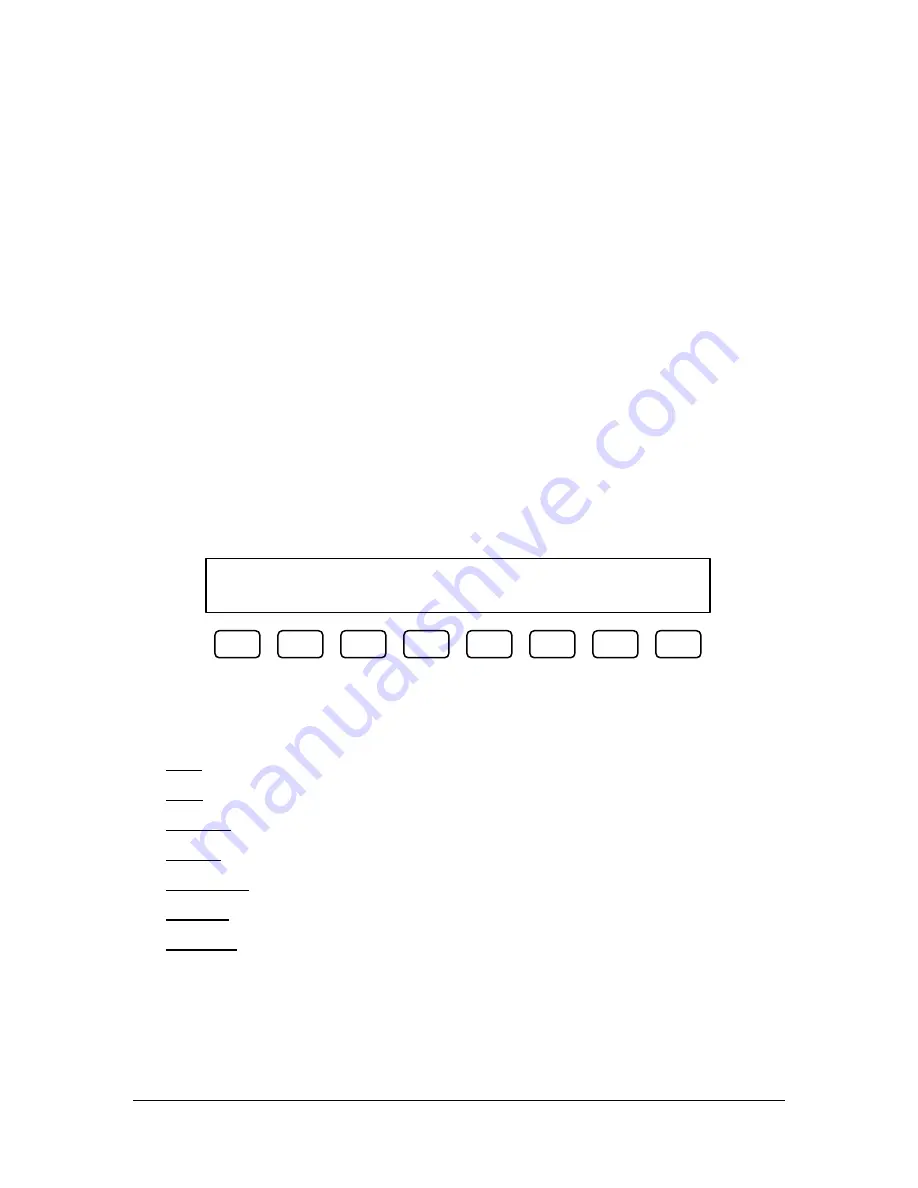

Flow

00.00cc

DEV=00.0%

Error

EXIT

UP

DOWN

UP

DOWN

*ON

OFF

F1

F2

F3

F4

F5

F6

F7

F8

Flow mode allows control over the flow monitor data that is used as a process check only during Auto

Cycle. These settings are used to determine the material volume and whether or not it is excessive

unless

superceded by commands in a path program. The error selection turns the process verification check on and

off. The error ON/OFF selection cannot be overridden by commands in a path program.

[F1] EXIT

– Leave Flow mode and return to Cycle Stop.

[F3] cc UP

– Increase the material target level. Maximum is 99 cc.

[F4] cc DOWN

– Decrease the material target level. Minimum is 0.00 cc.

[F5] DEV UP

– Increase the allowable deviation. Maximum is 99%.

[F6] DEV DOWN

– Decrease the allowable deviation. Minimum is 0%.

[F7] Error ON

– Turn the material flow error checking on. (default)

[F8] Error OFF

– Turn the material flow error checking off.

Summary of Contents for PVA2000

Page 9: ...Notes ...