Operation and Maintenance Manual Rev M(ii) 4/03

- 48 -

Maintenance

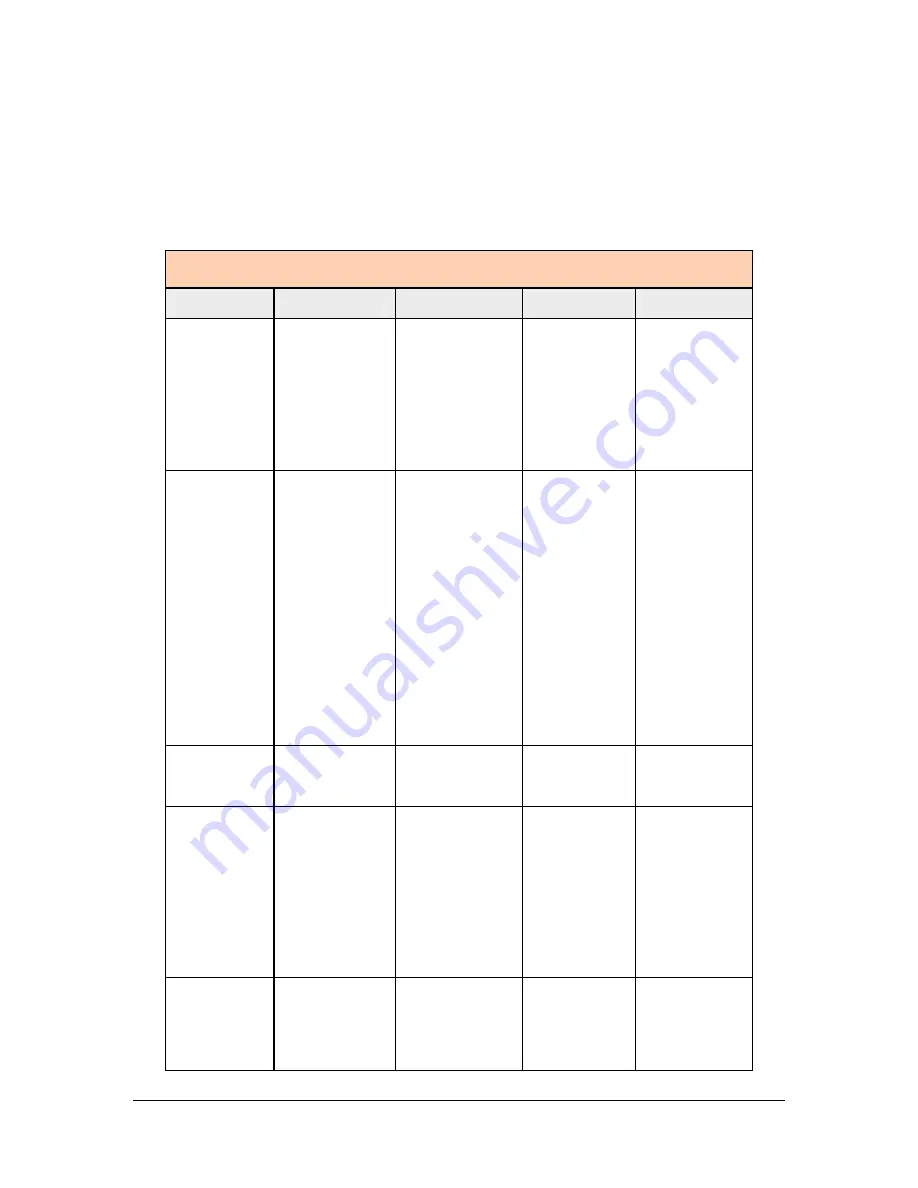

Schedule

Table 8 – Preventive Maintenance Schedule

Type Of Service

Service Area

Every Shift

Weekly

Monthly

Quarterly

Dispensing

Equipment

Check all fluid

pressures and

dispense weights.

Check for material

buildup on fixtures

and locating

surfaces.

Check for any leaks

around compression

fittings. Retighten

or replace if needed.

Inspect the fluid

delivery lines for

excessive wear.

Check the inline

material filter for

clogging.

Electro-

mechanical

components

Check motors for

overheating and

smooth operation.

Check for any

chaffing of wires,

pneumatic lines or

material lines.

Inspect enclosure

air filter, clean with

warm soapy water

as needed. Air dry

before reinstalling.

(PVA250™,

PVA750™ models

only.)

Grease the ball

screw slides with

Lithium Grease

(JIS Type 2).

Inspect all moving

cables for

excessive wear.

Conveyor

System

Clean conveyor

belts.

Check for material

and dust buildup on

the sensors.

Check the

conveyor belts

for wear.

Part-in-Place

Sensors

Clean with warm

water, a mild

solvent (like dish

soap) and a soft

cloth.

DO NOT

use moderate or

harsh solvents,

such as Isopropyl

Alcohol, Acetone,

OS120, etc.

Pneumatics

Check for proper

operation. Drain

any accumulated

water from the main

Filter/Regulator.

Check the slides

for wear and

smooth operation.

Summary of Contents for PVA2000

Page 9: ...Notes ...