DURAWATT

®

ELECTRIC WATER HEATER

PV500-6 09/07

13

SUPERTANK

™

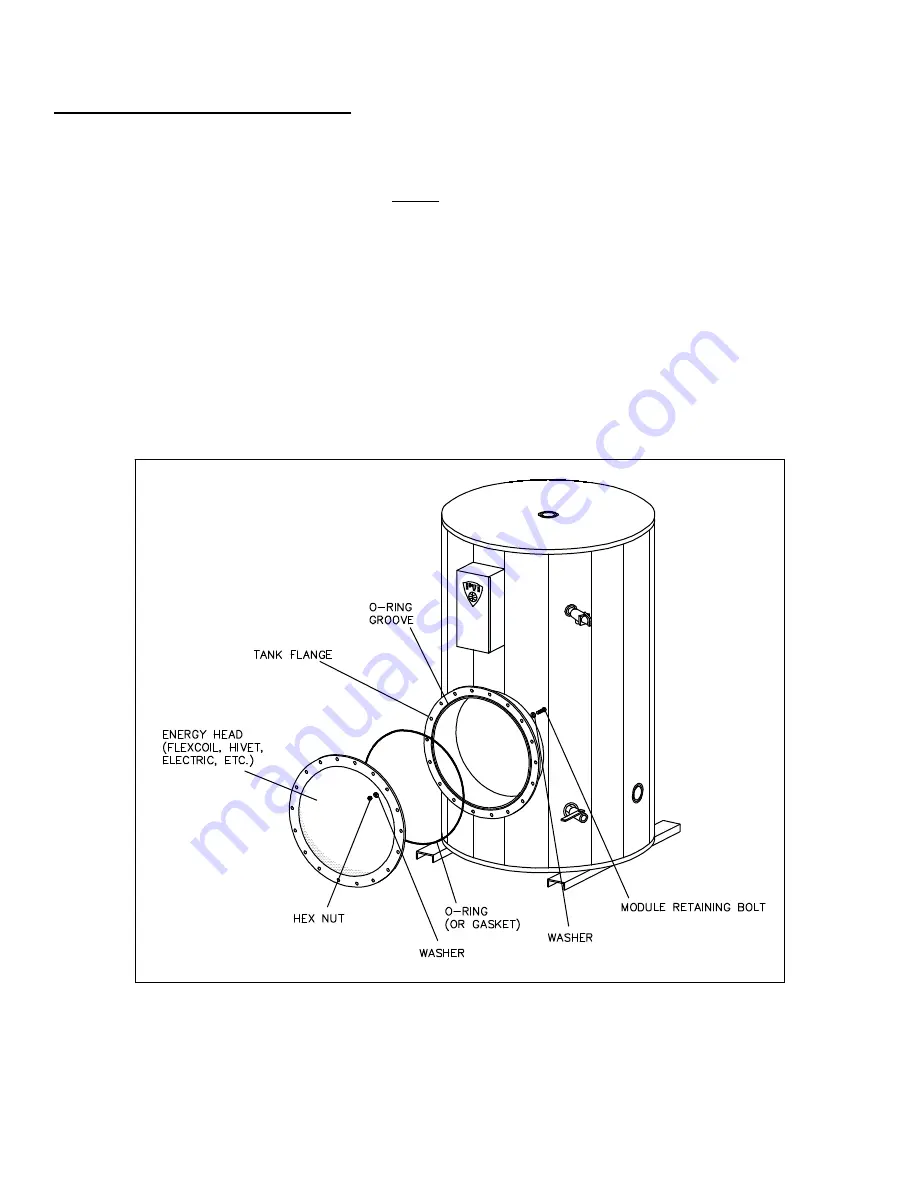

BOLTED HEAD REMOVAL

SUPERTANK

™

water heaters and storage tanks will have one or more removable heads or bolted tank sections. The

heads are used to mount an energy module (i.e. TURBOPOWER

®

module, electric elements, QUICKDRAW

®

or steam or

water heat exchanger heating elements) or bolted head for access to the tank. If a head or module is removed during the

course of maintenance, replace the O-ring and all special high quality 9/16”-12 NC, grade 8 bolts, washers and nuts with

identical parts available from your PVI representative or directly from PVI. Do not reuse or substitute these special

fasteners with similar grade 8 bolts, washers and nuts. Install the flange bolts and nuts with a flat washer under each bolt

head and nut. First, snug them in an alternating star pattern. Then, using a calibrated torque wrench, and in an alternating

star pattern, tighten the bolts in 2 increments: 95 ft lbs and 145 ft lbs. Use a small amount of silicone RTV to hold the o-

ring in place while positioning the flanged head or heat exchanger. Apply adhesive sparingly!

Contact PVI at 1-800-433-5654 for replacement Fastener Kits and O-Ring Replacement Instructions.

IMPORTANT

: Mark one hole on head and on tank flange for reference when removing head. Be certain to align these

holes during reassembly to insure the original gasket or O-ring mating surfaces will be correctly positioned.

Typical Vertical SUPERTANK

™

Bolted Head Attachment

FIGURE 13