CONQUEST

®

WATER HEATER

51

PV500-71 02/16

17. NSF FOOD SERVICE INSTALLATION GUIDELINES

All Conquest water heater models that have the Intertek ETL Sanitation mark on the information decal affixed to the

front of the appliance are listed to NSF 5.

This section provides additional information for architects, designers, and contractors in food service installations

requiring compliance with NSF codes. NSF/ANSI 5 establishes health and sanitation requirements for the materials,

design and construction of commercial water heaters. All Conquest water heaters are certified for compliance with

NSF-5 by ETL Intertek and are therefore recognized as suitable for installation and use in commercial food service

appllications when installed and used according to these instructions.

WARNING:

Do not use a pressurized water source to clean this water heater. If the food service installation

requires pressurized washing, the water heater must be isolated from water spray. Failure to isolate the

heater from pressurized water may cause a hazardous condition resulting in property damage or high

voltage electrical shock, causing personal injury or death.

Conquest water heaters can be adjusted to operated at temperatures up to 190ºF. Refer to the “Temperature

Setting” section of this manual for instructions to adjust the thermostat to the desired temperature.

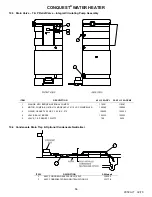

NSF Installation -

The NSF 5 listed Conquest water heater requires no modification to become NSF 5 compliant, is

designed to supply potable hot water and is not intended or suitable for other purposes. Where feasible, the water

heater should be located seperate from food and utensil handling areas. When this is not possible in a food service

installation, the water heater must be sealed to the floor to prevent water from accumulating underneath. The floor

must be clean, smooth and level for adequate sealing. Seal the water heater to the floor using an RTV sealant

(such as Red Devil 0826, Saf-T-Lok 732 or RTV 102 or an equivalent). Follow the sealant manufacturers

instructions to lay a bead of sealant between the edge of the heater base and the floor. The supplied covers over

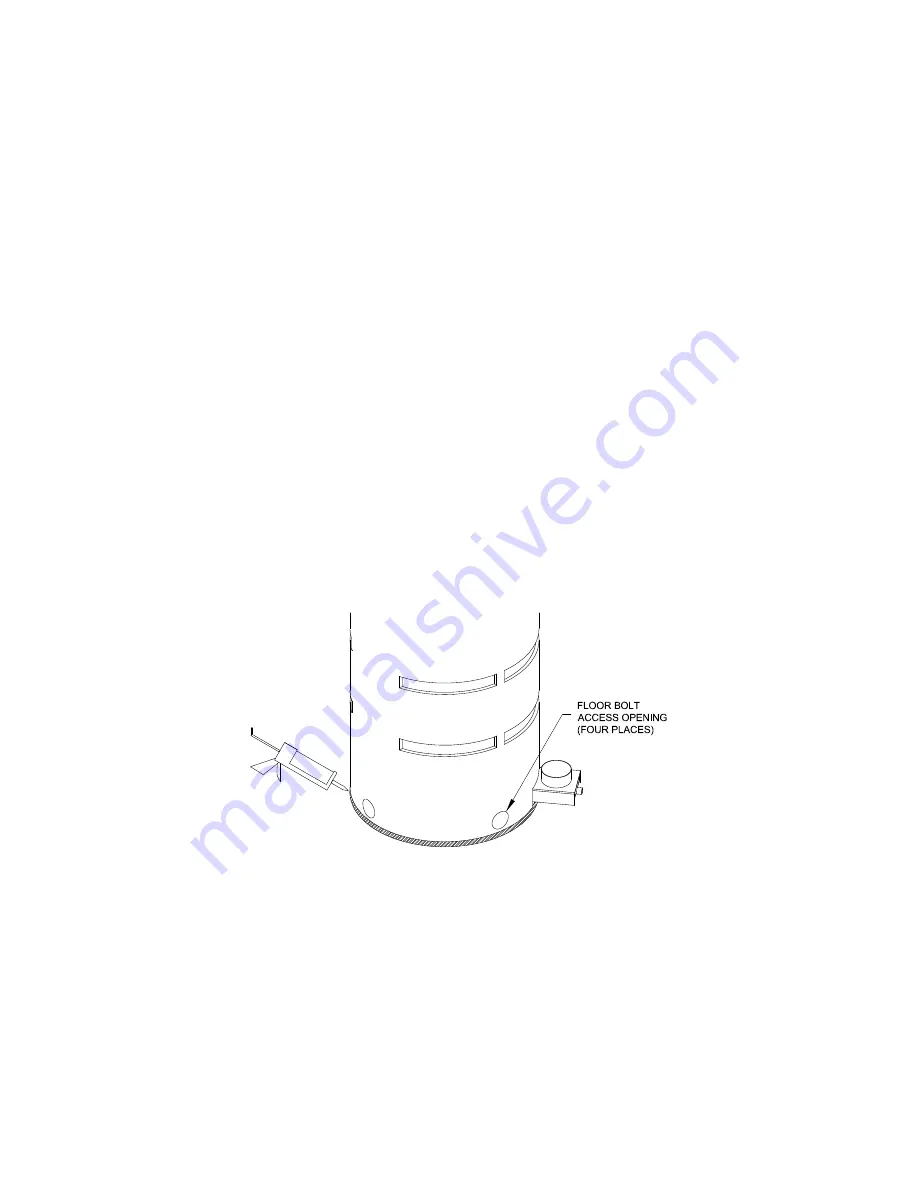

the four floor bolting access openings must be installed.

NSF Service and Maintenance -

NSF 5 for food service installations require the appliance and its installation to

prevent harborage of vermin. Tight construction of the properly installed and assembled heater enclosure does not

provide a haven for pests. If the floor bolting access covers do not seal completely, they must be replace with direct

replacement covers, available from PVI.

18. TROUBLESHOOTING

PROCEDURE

Before troubleshooting the system, check the following items:

•

Verify all mechanical and electrical connections are secure and tight.

•

Verify all system wiring is correct.

•

Verify there is a proper system ground. The igniter, flame sensor, and ignition module must share a common

ground with the burner.

Nuisance shutdowns are often caused by a poor or erratic ground.

•

Follow the “Initial Startup” instructions in section 15 as the first step in any troubleshooting.

•

Verify that the system is powered and that the thermostat is calling for heat.

•

If the control displays an error code on the red diagnostic LED, troubleshoot per

Section 11.2 Alarm Messages –

Diagnostic Codes.

The LED will flash on for 1/10 second, then off for 2/5 second during a fault condition.

The pause between fault codes is 8 seconds.