POWER VTX

®

WATER HEATER

15

PV500-68 06/16

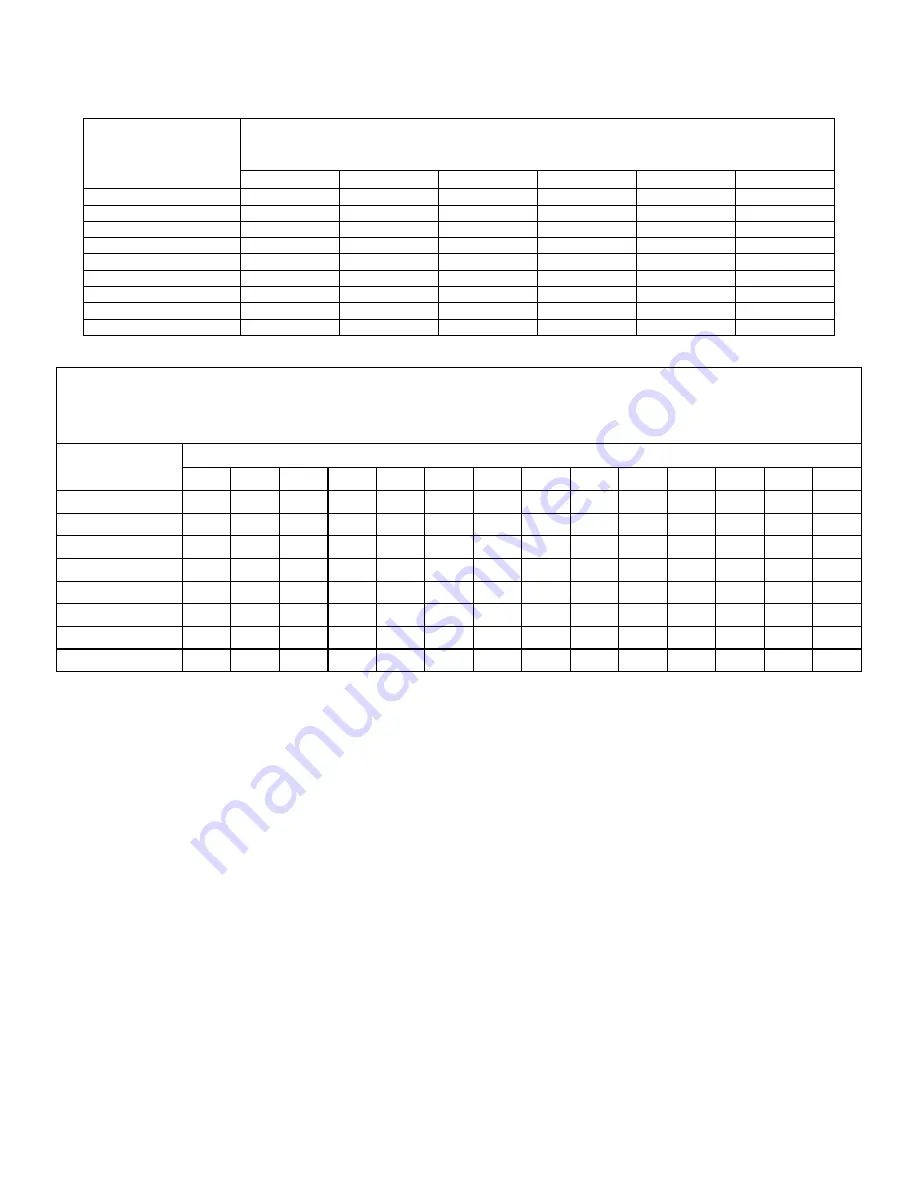

Use the following table to determine the possible pipe size based on distance from gas meter for a Single Unit

Installation using Schedule Metallic Gas Pipe.*

*See NFPA 54 National Fuel Gas Code for actual pipe size selection and for sizing Propane gas piping

*See NFPA 54 National Fuel Gas Code for actual pipe size selection and for sizing Propane gas piping

6.6 Appliance Isolation during Gas Supply Piping Pressure Test

1. The appliance and its provided manual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of ½ PSI (3.5 kPa).

2. The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than ½ PSI (3.5

kPa).

3. The appliance and its gas connection must be leak-tested before placing it in operation.

6.7 Gas Connection

1. Safe operation of unit requires adequate gas supply with the required static and dynamic (flow) pressures. Actual

piping selection depends on many variables that must be carefully considered by the gas piping system

designer.

2. Do not select gas pipe sizes based only on the supplied tables. These tables are for use by the gas piping

system designer as a reference in checking pipe size selections.

3. Gas pipe size may be larger than heater connection.

4. Installation of a union is suggested for ease of service.

5. Install a manual main gas shutoff valve on the gas supply piping connected to the appliance to isolate the burner

and gas train from main supply gas in compliance with NFPA 54 National Fuel Gas Code and most local Codes.

6. The gas system installer must clearly identify the emergency shut-off device.

7. A sediment trap (drip leg) MUST be provided in the inlet of the gas connection to the unit.

8. The combination gas valve incorporates an internal vent limiter. Venting to outdoors is not allowed.

Equivalent Feet

From Meter

SINGLE UNIT INSTALLATION SUGGESTED PIPE SIZE

Maximum Capacity for Natural Gas*

MBTU/HR Based on 0.5" W.C. Pressure Drop**

1-1/4" 1-1/2" 2"

2½"

3"

4"

25

860 1320 2475 3900 7000 -

40

660 990 1900 3000 5300 -

60

-

810 1520 2400 4300 -

80

-

690 1300 2050 3700 -

100

-

620 1150 1850 3250 6700

125

-

- 1020 1650 2950 6000

150

-

-

950 1500 2650 5500

175

-

-

850 1370 2450 5000

200

-

-

800 1280 2280 4600

MULTIPLE UNIT INSTALLATIONS SCHEDULE 40 METALLIC GAS PIPE SIZE CHART*

Maximum Capacity of Pipe in Thousands of BTU’s per hour for gas pressures of 14 Inches Water Column (0.5

PSIG) or

less and a pressure drop of 0.05 Inch Water Column (Based on NAT GAS, 1025BTU’s per Cubic Foot of Gas and

0.60 Specific Gravity).*

Nominal Iron Pipe

Size, Inches

Length of Pipe in Straight Feet

10 20 30 40 50 60 70 80 90 100 125 150 175 200

3/4

369 256 205 174 155 141 128 121 113 106 95 86 79 74

1

697 477 384 328 292 267 246 256 210 200 179 164 49 138

1 1/4

1400 974 789 677 595 543 502 472 441 410 369 333 308 287

1 1/2

2150

1500

1210

1020 923 830 769 707 666 636 564 513 472 441

2

4100 2820 2260 1950 1720 1560 1440 1330 1250 1180 1100 974 871 820

2 1/2

6460 4460 3610 3100 2720 2460 2310 2100 2000 1900 1700 1540 1400 1300

3

11200 7900 6400 5400 4870 4410 4000 3800 3540 3300 3000 2720 2500 2340

4

23500

16100 13100 11100 10000 9000 8300 7690 7380 6870 6150 5640 5130 4720