INSTRUCTIONS

1.

Fit the propeller onto the propeller shaft, just like a fixed propeller. Be sure that the thrust

washer is on the spline before fitting the Max-Prop onto the spline. Without the thrust

washer the propeller will be loose fore and aft on the spline, and will damage the SailDrive

or propeller.

2. Tighten the nut onto the spline. Align the holes in the back of the nut with the groves in

the central hub, so that the two shaft nut lock screws can be tightened in place. Insert and

tighten the center locking bolt into the back of the nut. Secure it with the set screw for the

center locking bolt.

3. Fit the zinc and secure it with the three allen bolts. Make sure that the zinc and the

propeller are clean to insure good contact.

4.

Fill the prop with marine grease (supplied) using a grease fitting (supplied) inserted into the

grease holes on the side of the propeller marked “GREASE”. The Max-Prop Easy propeller

works properly only if the central body is completely filled with the correct grease. Verify

that the grease is oozing from the rotating joints between the central part and the hub, so

that all of the moving surfaces are perfectly greased. The grease used must be a type of

grease approved by Max-Prop so it will remain fluid after years of use and will not get too

stiff in cold water. Follow steps 4.1 through 4.9 on page 3. We recommend Lubriplate 130AA

calcium based grease.

TIP:

Watch our YouTube video on how to grease a

propeller, visit

https://youtu.be/Pr_aEJgugjM

Or scan the QR code with a mobile device.

Thread Diameter

Torque in Ft/lbs

16mm

50 ft. lbs.

20mm

60 ft. lbs.

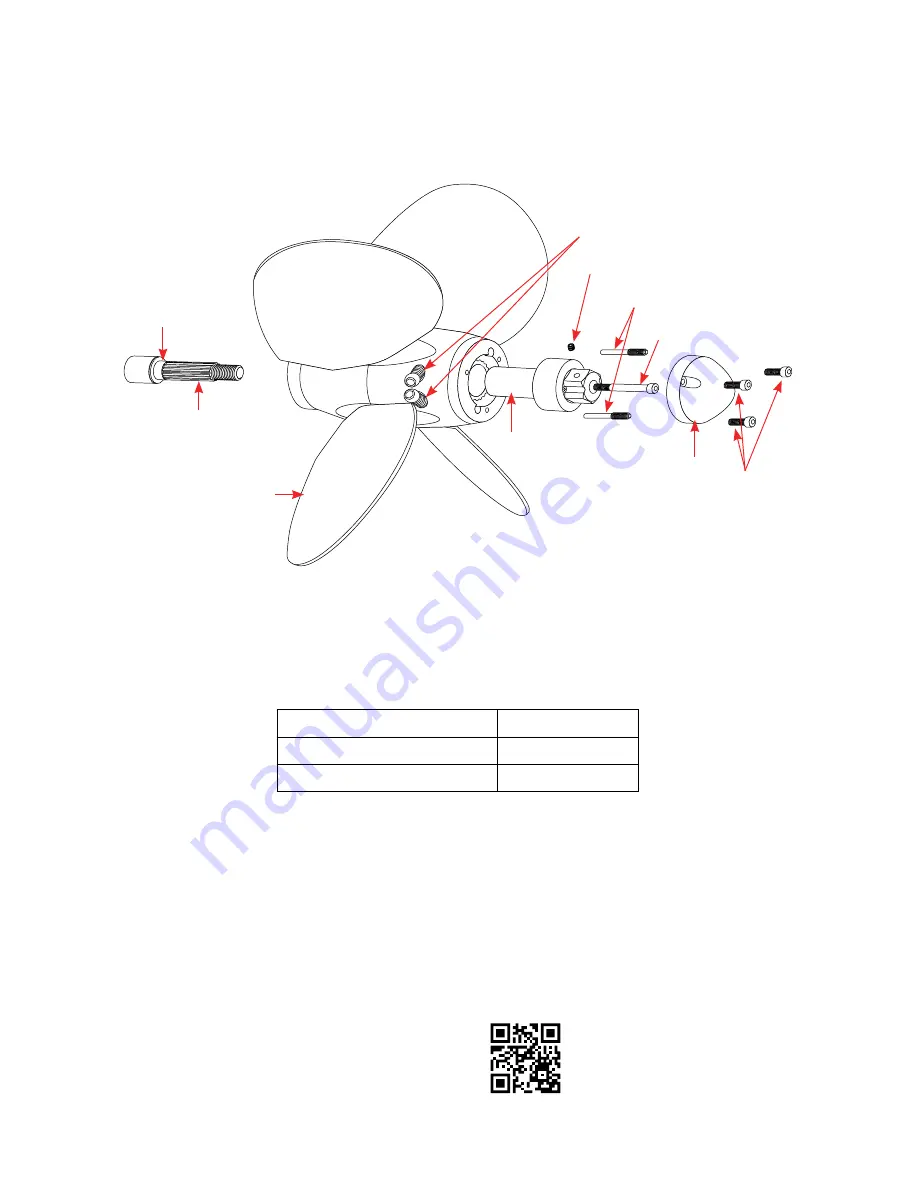

2

Fig.1

Spline

Thrust Washer

Prop

Shaft Nut

Pitch Adjustment Bolt

Set Screw For Locking Bolt

Zinc Bolt

Shaft Nut Locking Screws

Center Locking Bolt

Zinc Anode

Summary of Contents for Max-Prop EASY 2 Blade

Page 10: ...Notes 9 ...

Page 11: ...Notes 10 ...