INSTALLATION AND OPERATION MANUAL SOLAR MODULES Q.PEAK DUO XL-G11S.X / BFG

INSTALLATION AND OPERATION MANUAL SOLAR MODULES Q.PEAK DUO XL-G11S.X / BFG

8

9

2 Planning

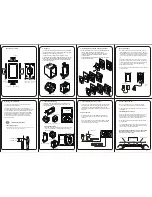

2.3 Mounting options

REQUIREMENTS OF ALL MOUNTING OPTIONS

The loads in the table are related to the mechanical stability of the solar modules. The mechanical stability of the mounting system

including clamps has to be evaluated by the system supplier. The listed test load values have been determined with the following

clamp parameters: clamp width = 1.57 in (40 mm) and clamp depth = 0.39 in (10 mm).

The system installer is responsible for the determination of location-specific load requirements.

Ensure that the connection cables of the junction box do not run between laminate and mounting rails.

Modules bend under load. Therefore, sharp objects (e.g. screws, ballast stones, rail ends, rails with burrs or sharp corners) must

not be placed near the module backside so as not to touch the laminate under load.

Ensure that the junction boxes do not touch the mounting structure (e.g. shorts rails, ballast, etc.) or the rooftop under load.

Clamps or insertion profiles etc. must not touch the glass (even under load).

Unbalanced loads (e.g. snow overhangs, snowdrifts) which result in locally significantly increased loads must be removed or

avoided by technical measures.

A minimum support depth of 0.59 in (15 mm) is required on the back side of the module.

Loads according to IEC 61215-2:2016 and UL 61730-2:2017 except for design loads lower than 1600 Pa which do

not fulfill the requirements of the standards. The test procedure is always according to IEC 61215-2:2016.

Design loads result from the safety factor 1.5.

Mounting options with clamps

The illustrated installation options apply for both horizontal and vertical module orientation.

Module

Clamp

Mounting rail

4 CLAMPS ON LONG SIDE &

2 CONTINUOUS RAILS PARALLEL TO SHORT SIDE

4 CLAMPS ON LONG SIDE (SHORT RAILS ALLOWED)

CL1a

L

CL1b

L

0.59 - 4.33

(15 - 110)

POSITION OF

CLAMPS* [in]

TEST LOAD

PUSH / PULL [Pa]

DESIGN LOAD

PUSH / PULL [Pa]

POSITION OF

CLAMPS* [in]

TEST LOAD

PUSH / PULL [Pa]

DESIGN LOAD

PUSH / PULL [Pa]

L

15.8 - 21.7

(400 - 550 mm)

3600 / 2400

2400 / 1600

L

7.9 - 21.7

(200 - 550 mm)

2100 / 2400

1400 / 1600

CL1a

These mounting options are not recommended as mounting rails will cast shade on the module rear side.

Ensure that module frame is fixed directly on the rail of the substructure (no spacer allowed between the

module and substructure).

CL1b

Using of short mounting rails are permissible, if they overlap with the module less than 4.33 in (110 mm).

Maintain a minimum distance (clearance) of ≥ 1.38 in (35 mm) between frame bottom edge and roof top or

ballast.

*

Distance between outer edge of module and middle of the clamp.

4 CLAMPS ON LONG SIDE &

2 CONTINUOUS RAILS UNDERNEATH LONG FRAME PARTS

2 CLAMPS ON LONG SIDE, 2 CLAMPS ON SHORT SIDE

CL3

L

CL5

L

S

POSITION OF

CLAMPS* [in]

TEST LOAD

PUSH / PULL [Pa]

DESIGN LOAD

PUSH / PULL [Pa]

POSITION OF

CLAMPS* [in]

TEST LOAD

PUSH / PULL [Pa]

DESIGN LOAD

PUSH / PULL [Pa]

L

15.8 - 21.7

(400 - 550 mm)

3600 / 2400

2400 / 1600

S

0.79 (20 mm)

2400 / 2400

1600 / 1600

L

27.6 (700 mm)

CL3

Ensure that module frame is fixed directly on the rail of the substructure (no spacer allowed between the

module and substructure).

Minimum support depth of 0.59 in (15 mm) is required on the back side of the module.

CL5

Minimum required support depth on the module backside is 0.39 in (10 mm) on long frame side and 0.59 in

(15 mm) on short frame side.

*

Distance between outer edge of module and middle of the clamp.