20

21

INSTaLLaTIoN aND oPeraTIoN MaNUaL SoLar MoDULeS GeNeraTIoN 3 (G3) – HaNWHa Q CeLLS aUSTraLIa PTY LTD

INSTaLLaTIoN aND oPeraTIoN MaNUaL SoLar MoDULeS GeNeraTIoN 3 (G3) – HaNWHa Q CeLLS aUSTraLIa PTY LTD

21

Protective Grounding

Ä

the modules must be grounded in accordance with the

local statutory regulations.

functional grounding

•

When using an installation tilt of < 5° a functional

grounding at the negative generator conncetion must

be implemented.

Ä

ensure that the difference of potential between the

negative generator connection and the Pe(N) of every

mPP tracker of the respective inverters is 0 V.

Ä

Follow the directions of the inverter manufacturer.

Ä

only use inverters which include lincensed grounding

kits.

5 GroUNDING

DANGER!

Risk of fatal injury due to electric shock!

Ä

Do not attempt to fix any problems yourself (e.g.,

glass cracks, damaged cables).

Ä

Please contact an installer or Q ceLLs technical

customer service Department.

6

faULTS aND DefeCTS

Ä

Do not disconnect modules yourself.

Ä

Please commission a trade specialist.

Ä

Dispose of modules in accordance with the local disposal

regulations.

7 DISPoSaL

Q ceLLs solar modules are known for a long operating

life and minimal maintenance effort and expense. Dirt

and grime are usually washed away by rain. if the module

is fully or partially shaded by dirt or debris (e.g., plants,

bird droppings), it needs to be cleaned to prevent a loss

of performance.

Maintenance

Ä

the system should be inspected by an installer annually

to check the following:

•

all system components sit securely and are corrosion

free.

•

the connection is secure and all electrical components

are clean and undamaged.

Cleaning

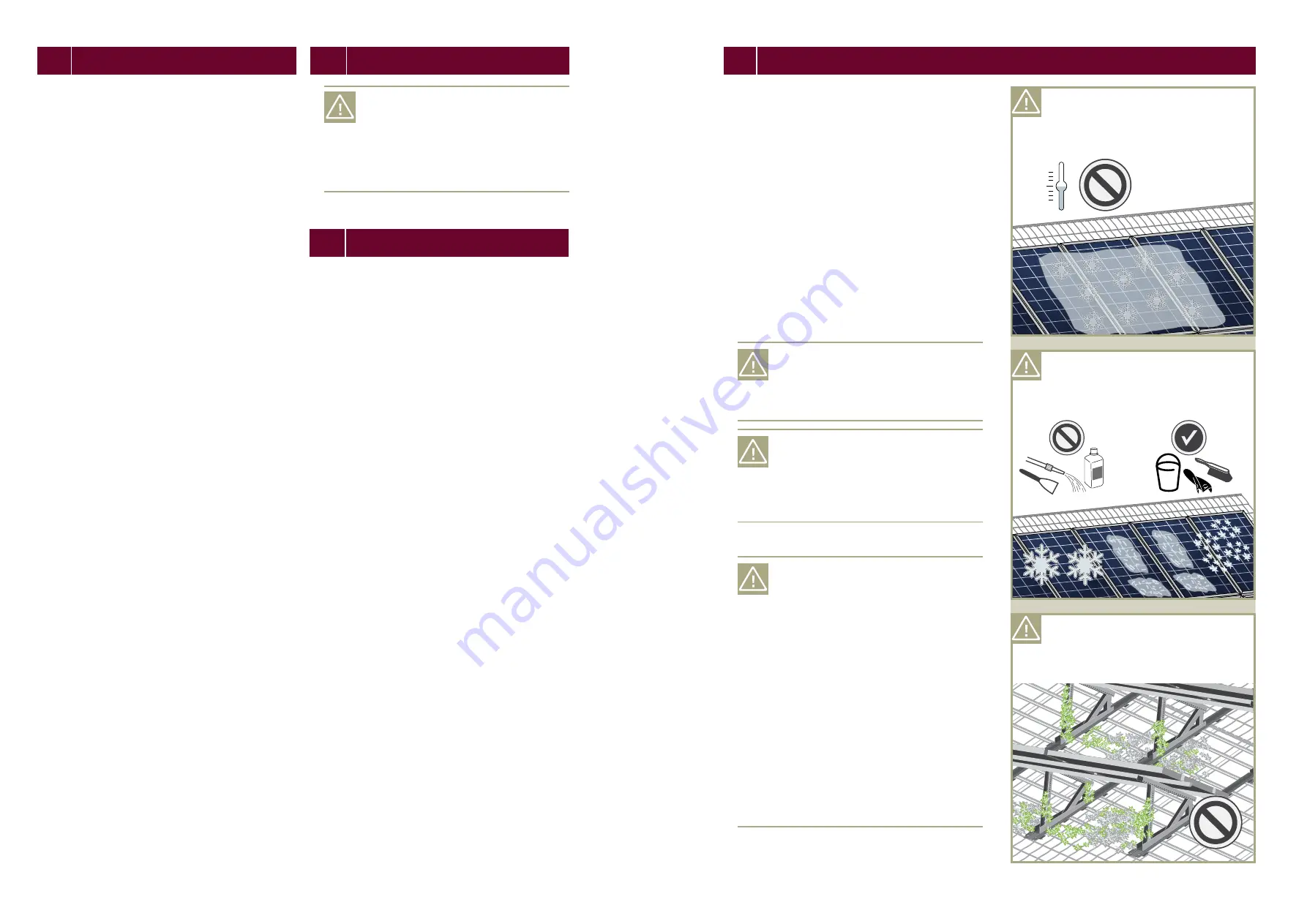

WARNING!

Risk of injury due to hot and

live modules!

Ä

only clean modules that have cooled down.

Ä

Do not carry or wear any electrically conductive parts.

WARNING!

Risk of falling due to unsecured

access!

Ä

Never access the installation area alone or without

taking adequate security precautions.

Ä

Please commission a trade specialist.

clean the modules as follows:

NOTE!

Module surface damage may occur!

Ä

Remove snow and ice without force (e.g. with a very

soft broom)

Ä

Do not scratch off dirt.

Ä

Rinse dirt off with lukewarm water (dust, leaves, etc.)

Ä

use a soft cellulose cloth (kitchen roll) or sponge to

carefully wipe off stubborn dirt. Do not use micro fleece

wool or cotton cloths.

Ä

use an alcohol based glass cleaner. Do not use abrasive

detergents or tensides.

isopropyl alcohol (iPA) can be used selectively to remove

stubborn dirt and stains within one hour after emergence.

Ä

Please follow the safety guidelines provided by the iPA

manufacturer.

Ä

Do not let iPA run down between the module and the

frame or into the module edges.

Ä

Free the substructure from any dirt and

debris (leaves, bird nests, etc.).

Ä

Remove dirt with lukewarm water, a

broom, or a soft cloth.

Ä

Do not use tensides, scrapers, or any

high-pressure water cleaning equipment.

NOTE

! Module damage may occur!

Ä

Do not clean modules with water if there

is a risk of frost.

0°

8

CLeaNING aND MaINTeNaNCe