8

9

INSTALLATIoN AND oPErATIoN MANUAL SoLAr MoDULES GENErATIoN 4 (G4) – HANwHA Q CELLS GMBH – NA

INSTALLATIoN AND oPErATIoN MANUAL SoLAr MoDULES GENErATIoN 4 (G4) – HANwHA Q CELLS GMBH – NA

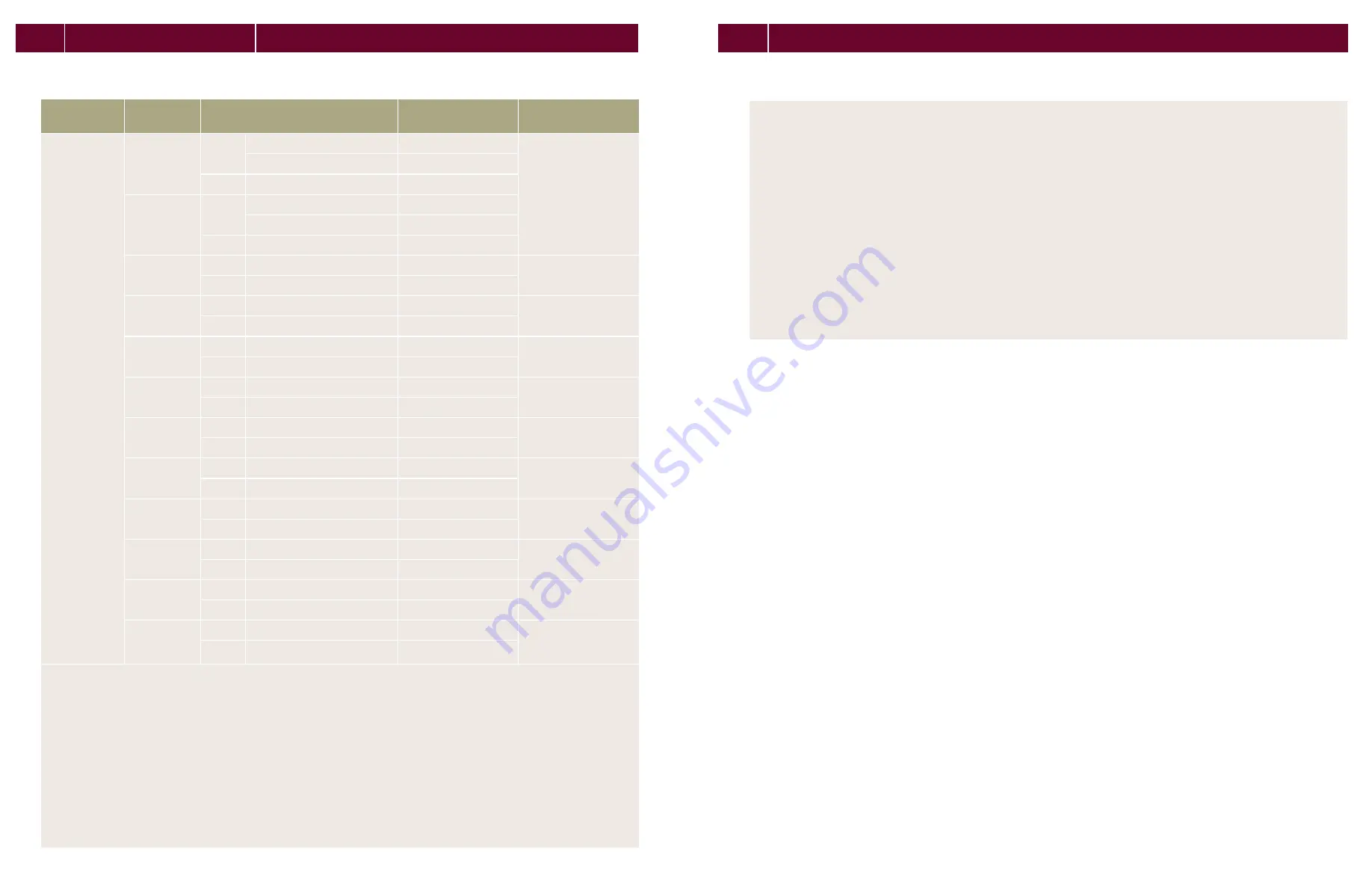

2 PLANNING

2.3 Mounting options

Specifications

MoDULE TyPE

MoUNTING

oPTIoN

CLAMPING ArEA

1

[IN (MM)]

ALLowED STATIC

LoAD² [PA]

TEST LoAD ACC. IEC

61215 PUSH/PULL [PA]

q.PRO-G4

q.PLUS-G4

q.PRO BFR-G4

q.PRO BLK-G4

CL1

Push

9.84 - 13.78 (250 - 350)

2700

5400/4000

>13.78 - 17.72 (>350 - 450)

1900

Pull

9.84 - 17.72 (250 - 450)

2400

CL1 extended

(min. 0.79 in)

Push

9.84 - 13.78 (250 - 350)

3600

>13.78 - 17.72 (>350 - 450)

3300

Pull

9.84 - 17.72 (250 - 450)

2400

CL3

Push

9.84 - 17.72 (250 - 450)

3300

5400/4000

Pull

9.84 - 17.72 (250 - 450)

2400

CL4

Push

0 - 11.81 (0 - 300)

1350

2400/2400

Pull

0 - 11.81 (0 - 300)

1200

FB1

Push

13.58 (345)

2200

5400/4000

Pull

13.58 (345)

2800

FB2

Push

13.58 (345)

3200

5400/4000

Pull

13.58 (345)

2800

FB1 (9.84 in

(250mm))

Push

9.84 (250)

2900

5400/4000

Pull

9.84 (250)

2800

FB2 (9.84 in

(250mm))

Push

9.84 (250)

3200

5400/4000

Pull

9.84 (250)

2800

IP1

Push

-

3200

5400/4000

Pull

-

3000

IP2

Push

-

1350

2400/2400

Pull

-

1200

CL5 hybrid

clamping

Push

11.81 - (300 - 400)

2700

2400/2400

Pull

11.81 - (300 - 400)

2700

CL2 without

substructure

support

Push

0 - 3.94 (0 - 100)

1200

2400/2400

Pull

0 - 3.94 (0 - 100)

1100

1

Distance between outer edge of module and middle of the clamp.

² Describes the maximum module surface load (vertical to the module surface) regarding safety factors (e.g. EUROCODE). For this

purpose, the load value determined by load tests according to various criteria: laminate overlay, plastic deformation, module failure,

and were divided with a safety factor. The minimum calculated load value corresponds to the maximum permitted load.

UNTING oPTIoN CL1

Ä

Ensure, that the subconstruction does not run below the junction box.

Ä

Ensure, that the connection cables of the junction box don‘t run between laminate and substructure.

MoUNTING oPTIoN CL1 ExTENDED

Ä

Ensure, that there’s distance of minimum 1.77 in (45 mm) between laminate backside and subconstruction respectively

that the distance between module frame backside and substructure is minimum 0.79 in (20 mm).

Ä

Ensure, that the connection cables of the junction box don‘t run between laminate and substructure.

MoUNTING oPTIoN CL4

Ä

Ensure, that the subconstruction runs exactly below the frame, not below the laminate (module less frame).

MoUNTING oPTIoNS FB1 AND FB2

Ä

Ensure, that the connection cables of the junction box don‘t run between laminate and substructure.

•

Use M8 corrosion-proof screws and washers (diameter 0.63 in (16 mm)).