15

INSTALLATIoN AND oPErATIoN MANUAL SoLAr MoDULES GENErATIoN 4 (G4) – HANwHA Q CELLS GMBH – NA

14

INSTALLATIoN AND oPErATIoN MANUAL SoLAr MoDULES GENErATIoN 4 (G4) – HANwHA Q CELLS GMBH – NA

Ä

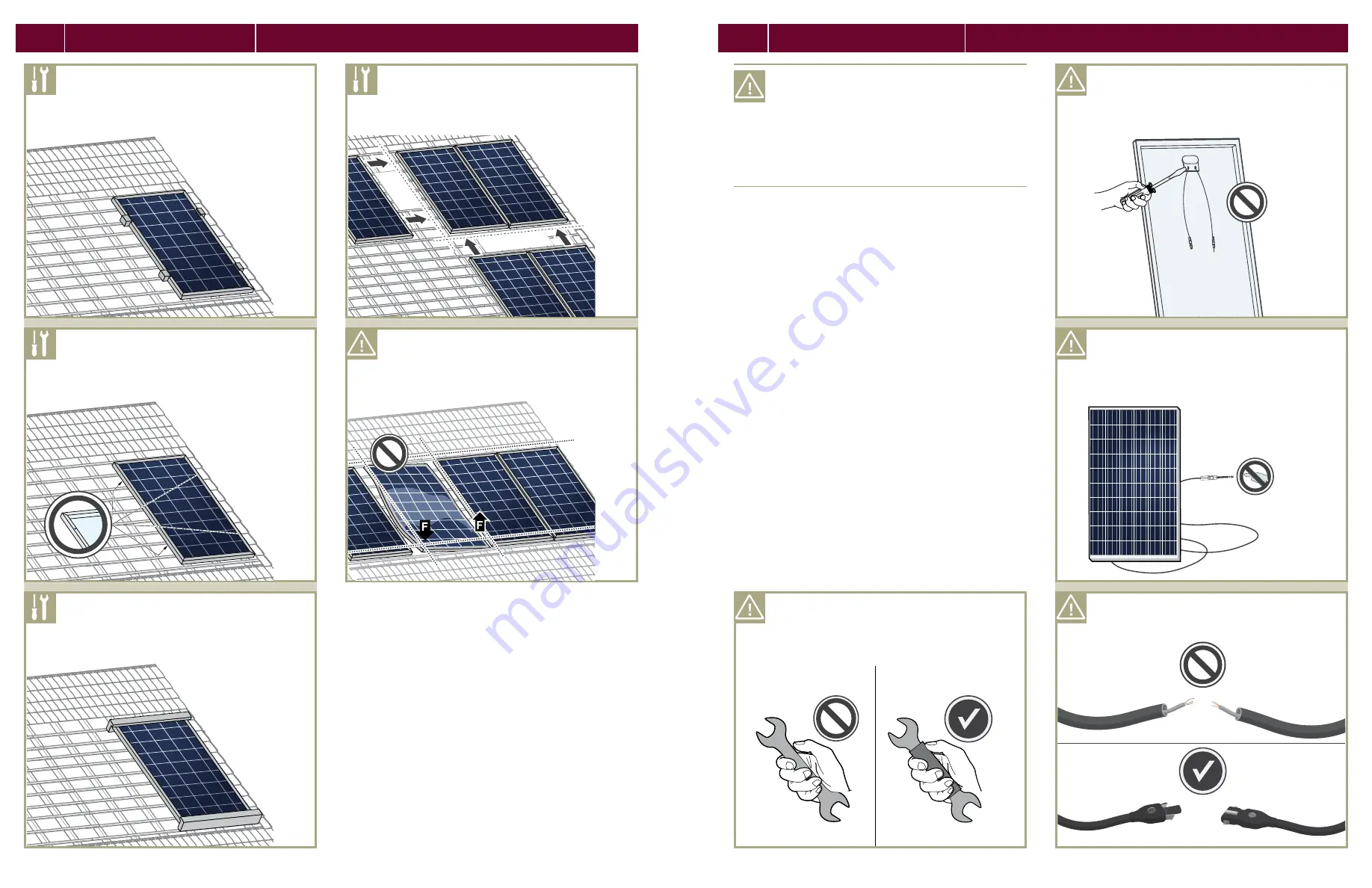

Maintain an interval of at least 0.39 in (10 mm)

between two modules along the short side and

0.20 in (5 mm) along the long side.

0.39 in (10mm)

0.20 in

(5 mm)

Option 2:

Ä

Install the module at the 4 mounting points, see

page 7.

Ä

Tighten screws according to manufacturer’s

instructions.

NOTE

! Module damage may occur!

Ä

Do not subject modules to mechanical tension.

Max. torsion 0.39 in/yd (10 mm/m).

Option 3:

Ä

Install the module using mounting profiles, see

page 7.

Option 1:

Ä

Fasten the module with 4 clamps in the specified

clamping range, see page 7.

Ä

Tighten clamps according to manufacturer’s

instructions.

3.3 Module installation

3 INSTALLATIoN

DANGER!

Risk of fatal injury due to electric shock!

When disconnecting an electric circuit carrying direct current,

electric arcs can occur that may result in life-threatening injuries.

Ä

Do NOT unplug the cable when under load.

Ä

Do NOT connect any exposed cable ends.

Ä

Do NOT touch the poles at the same time.

A solar module generates electrical current and voltage even at a

low intensity of illumination. Sparks and electric arcs may result

from the separation of a closed circuit. These can result in life-

threatening injuries. The danger increases when several modules

are connected in series.

Ä

Please ensure that the entire open circuit voltage is active even

at low levels of solar irradiation.

Ä

Please follow the valid national regulations and safety guidelines

for the installation of electrical devices and systems.

Ä

Please make sure to take all necessary safety precautions. With

module or phase voltages of more than 120 V, the extra-low

voltage range is exceeded.

Ä

Carry out work on the inverter and the wiring with extreme caution.

Ä

Ensure that the modules are disconnected at the inverter prior

to separation.

Ä

Be sure to observe the specified time intervals after switching off

the inverter. High-voltage components need time to discharge.

DANGER

! Risk of fatal injury due to electric shock!

Ä

Never open the junction box.

Ä

Change of bypass diodes is only allowed by

qualified and trained personnel in disconnected

and covered state.

DANGER

! Risk of fatal injury due to electric shock!

Ä

Never touch live contacts with bare hands.

Ä

Do not touch the poles at the same time.

Ä

Cover connectors by suitable protective caps

until installation.

DANGER

! Risk of fatal injury due to electric shock!

Ä

Insulate any exposed cable ends.

Ä

Only connect cables with plugs.

DANGER

! Risk of fatal injury due to electric shock!

Ä

Only use dry, insulated tools for electrical work.

4.1 Safety

4

ELECTrICAL CoNNECTIoN