6

Assembly and installation manual

QIM/QDB Mixer Series

QIM/QDB-M01

HOW TO INSTALL THE PIPING

GENERAL

This section provides some do’s and do not’s of piping which will aid in obtaining the maximum

efficiency and service from your pump. Piping should be independently supported at both the

suction inlet and discharge outlet. Care should be taken that piping is properly aligned and does

not put any strain on the pump casing. The piping should have as few bends as possible.

SUCTION PIPING

The suction piping should be short and follow a direct route with a minimum number of elbows

and fittings. Elbows should be located as far as possible from the suction inlet to prevent head

loss due to increased friction. Excessive friction losses in the suction line could result in pump

cavitation, causing poor performance, noise, vibration, damage to equipment and possible

damage to fluid.

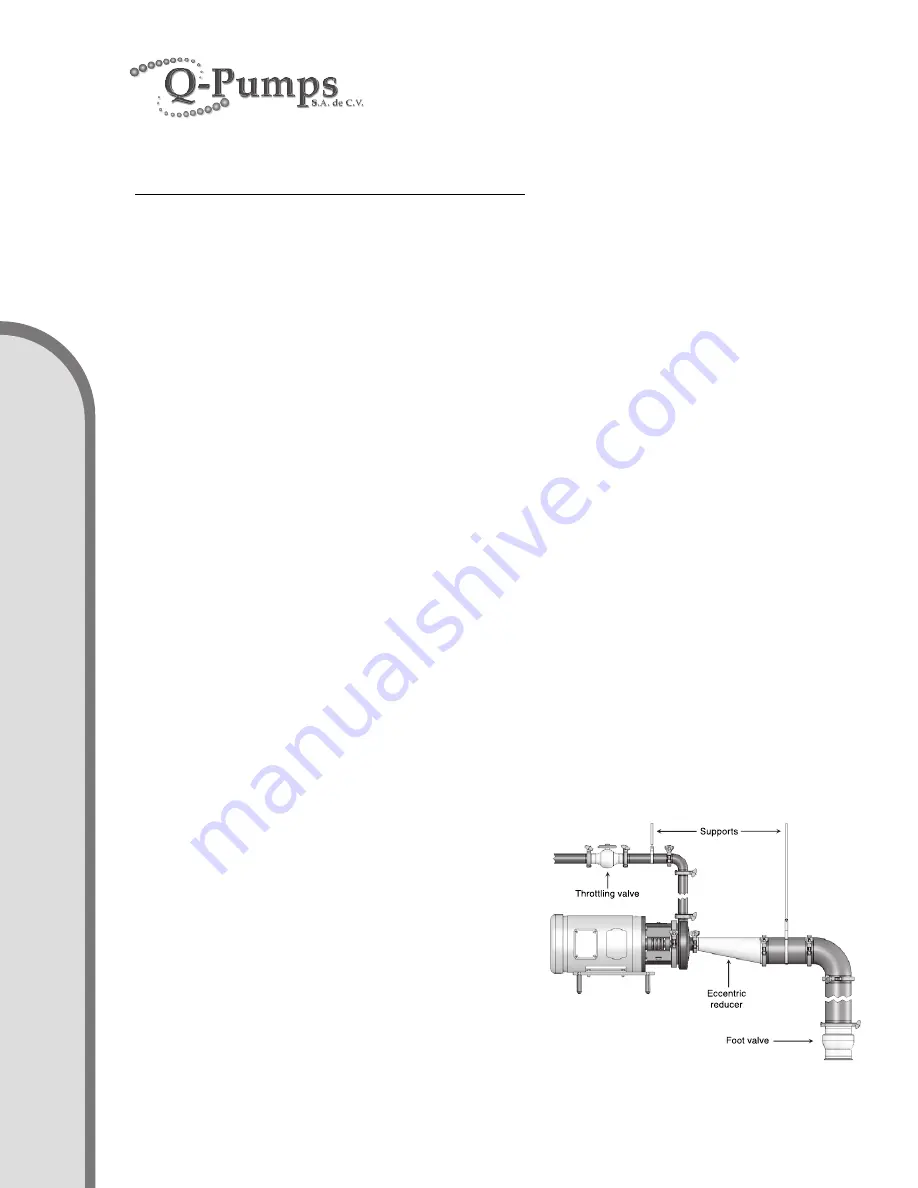

Whenever possible the diameter of the piping at the suction inlet should be increased in size, an

eccentric tapered reducer should be used instead of a concentric tapered reducer to prevent

air pockets from forming and impairing pump efficiency. In turn, the eccentric reducer may be

placed at the inlet of the pump and should be positioned so the straight side is up. A horizontal

suction pipe must have a gradual rise to the pump. A high point in the suction line will form an

air pocket and prevent proper pump operation. All joints in the suction line should be air tight, to

prevent air leakage which can reduce pump capacity and efficiency.

DISCHARGE PIPING

Position of the pump discharge is preferably either vertical or top horizontal. The discharge piping

should be short and direct with a minimum number of elbows and fittings. Elbows should not be

used at the discharge outlet, as the friction encountered would be increased, resulting in head

loss. However, use of a large discharge pipe than recommended may reduce the total pump

head, but increase the pump volume, which can cause pump vibration due to overload. Use

of a discharge pipe smaller than the pump discharge outlet increases the total pump head but

decreases the volume. If a reducer is required on the outlet port of the pump and the discharge

is vertical a concentric reducer should be used. If the

discharge is horizontal an ec centric reducer should be

used and should be positioned so the straight side is

down.

LOCATING VALVES

In suction lift applications where the lift is not very

high, it may be desirable to install a foot valve, to

facilitate priming, and to prevent draining off of the

liquid back to the source. A throttling valve should

be installed in the discharge piping to provide control

pump flow rate and prevent motor overload.

IN

ST

ALL

ATIO

N