6

—

TECHNICAL DATA

UNIVERSAL ROBOTS MANUAL — MAR 9, 2023 — RELEASE: V1.0.3

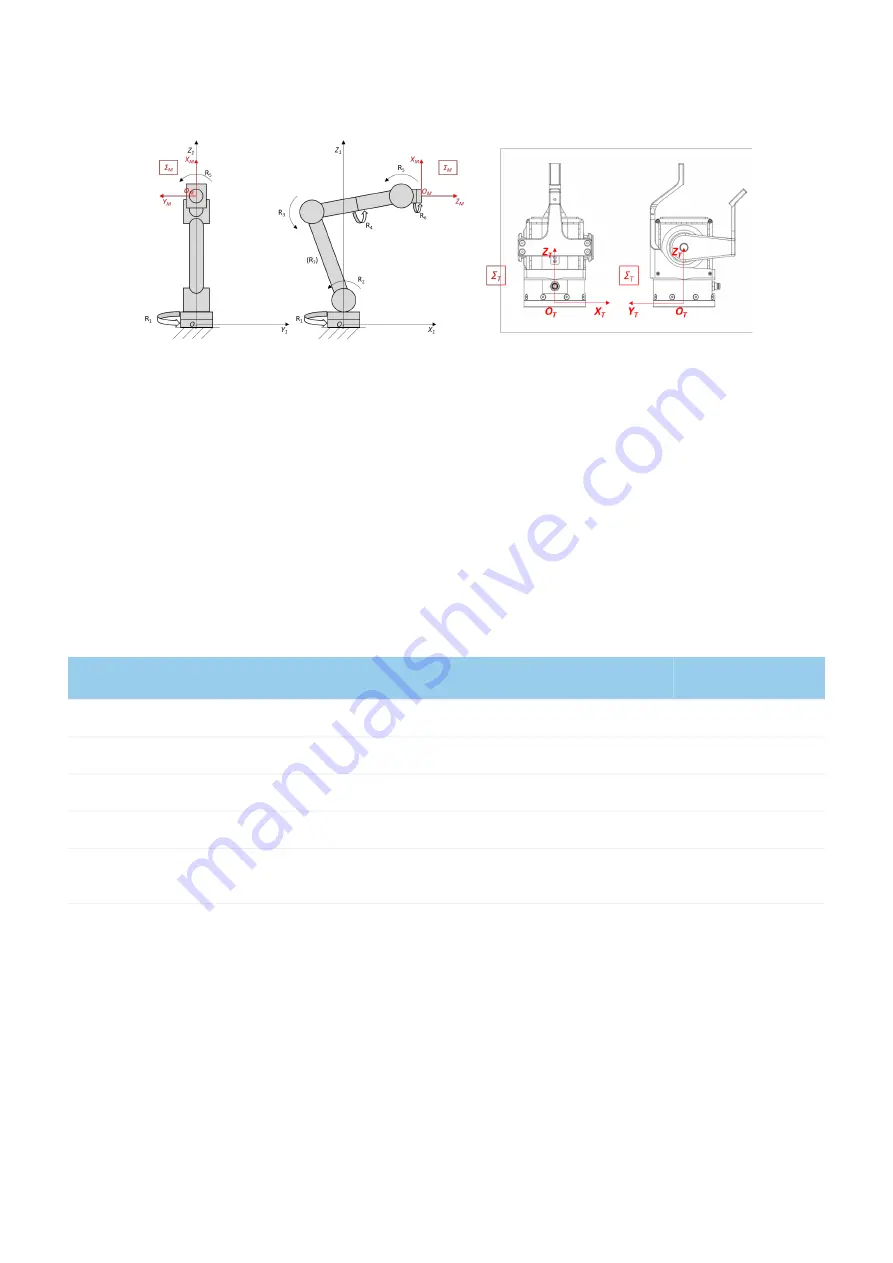

Figure 1. —

Robot Tool Coordinate System

On the left, it is represented the mechanical interface coordinate system

Σ

M

(O

M

; X

M

, Y

M

, Z

M

)

of

an

articulated robot, as defined by ISO 9787:2013. In particular, the center of the coordinate system,

O

M

, is

on the interface surface of the robot tool flange and the

Z

M

axis

is coincident with the tool flange axis of

symmetry. R

i

is the i-th revolute joint of the robot

and

(O

1

; X

1

, Y

1

, Z

1

)

is

the base coordinate system of the

robot.

On the

right, there

is the Tool Coordinate

System,

Σ

T

(O

T

; X

T

, Y

T

, Z

T

)

, of the qbSoftClaw and the

center,

O

T

,

coincides with the center of mass of the device and its position is defined by the distance

from

O

M

.

The

Z

T

axis

is normal to the palm, outgoing positive, and

the

Y

T

axis

follows the proximal-distal direction and

orientation.

3.3 Mechanical characteristics

MINIMUM

NOMINAL

MAXIMUM

Payload

[kg]

—

—

3.70

Grasping force

[N]

0.5

—

64.0

Grasping time

[s]

—

—

1.0

Releasing time

[s]

—

—

1.0

Look at the graph for details. The grasping force in the graph refers to the component along the line joining

the centers of the two pads, so it depends on the size of the object