z

z

z

z

z

z

z

35

Checking the calibration

The laser instrument should be checked, like all measure instruments, before

use.

The inspection can be carried out most easily by doing a reverse

measurement. Therefore do the following steps:

Set up the instrument onto a stable fixing.

Turn the laser on and let it level.

Mount the receiver in a fixed distance, e.g. in 30 meter, and move it onto the

laser plane (display middle).

Now turn the instrument around each 90° and let the instrument level.

Measure in each case the difference to the first height.

If the deviation is smaller than ± 2mm, the instrument is within the

specification.

In case of larger deviations the instrument has to be calibrated.

Calibrating the QL320

General information:

The calibration of the instrument can be done by use. We recommend to

carry out the calibration attentively and carefully. For failures at

measurements and/or consequential damages through a wrong calibration no

liability can be taken over.

If you feel unsure doing the calibration, you should contact your authorised

dealer or the QBL Baulaser GmbH. We recommend to use a measuring

length of 50 meter for the calibration (= 100m after reverse measurement).

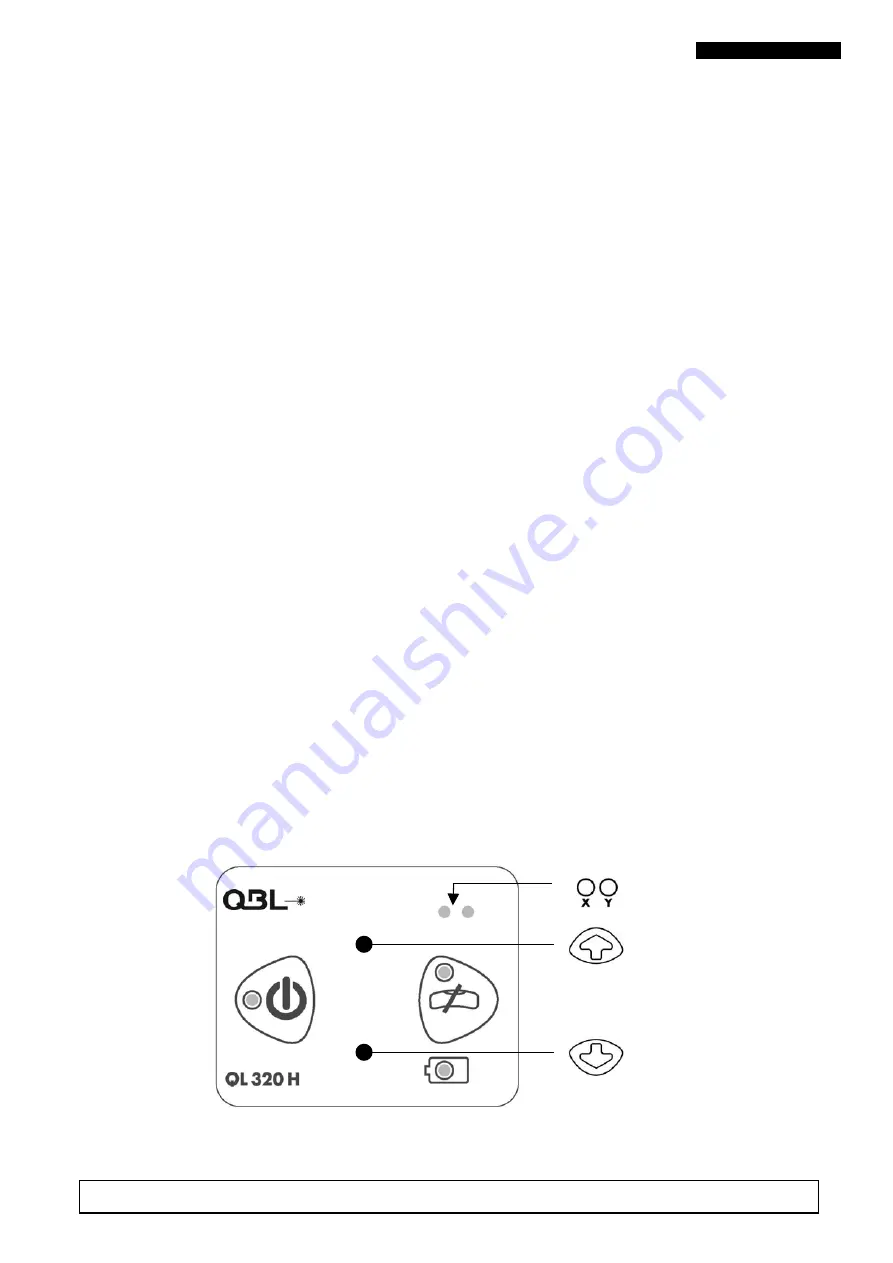

Remark for the calibration of the QL320H:

On laser type QL320H the arrow keys are not to be seen at the control panel

since they are not acting in normal use. The keys become active in the

calibration mode. Following illustration shows the position of the keys.