qcconveyors.com

| Introduction to Maintenance —

Troubleshooting Guidelines

| 23

Troubleshooting Guidelines

INTRODUCTION TO MAINTENANCE

CARET-LEFT

In the course of conveyor operation, periodic inspection of the conveyor system is required to prevent of any breakdowns and failures

Flextrac Series conveyors should be inspected while the system is running as well as when it is shut down.

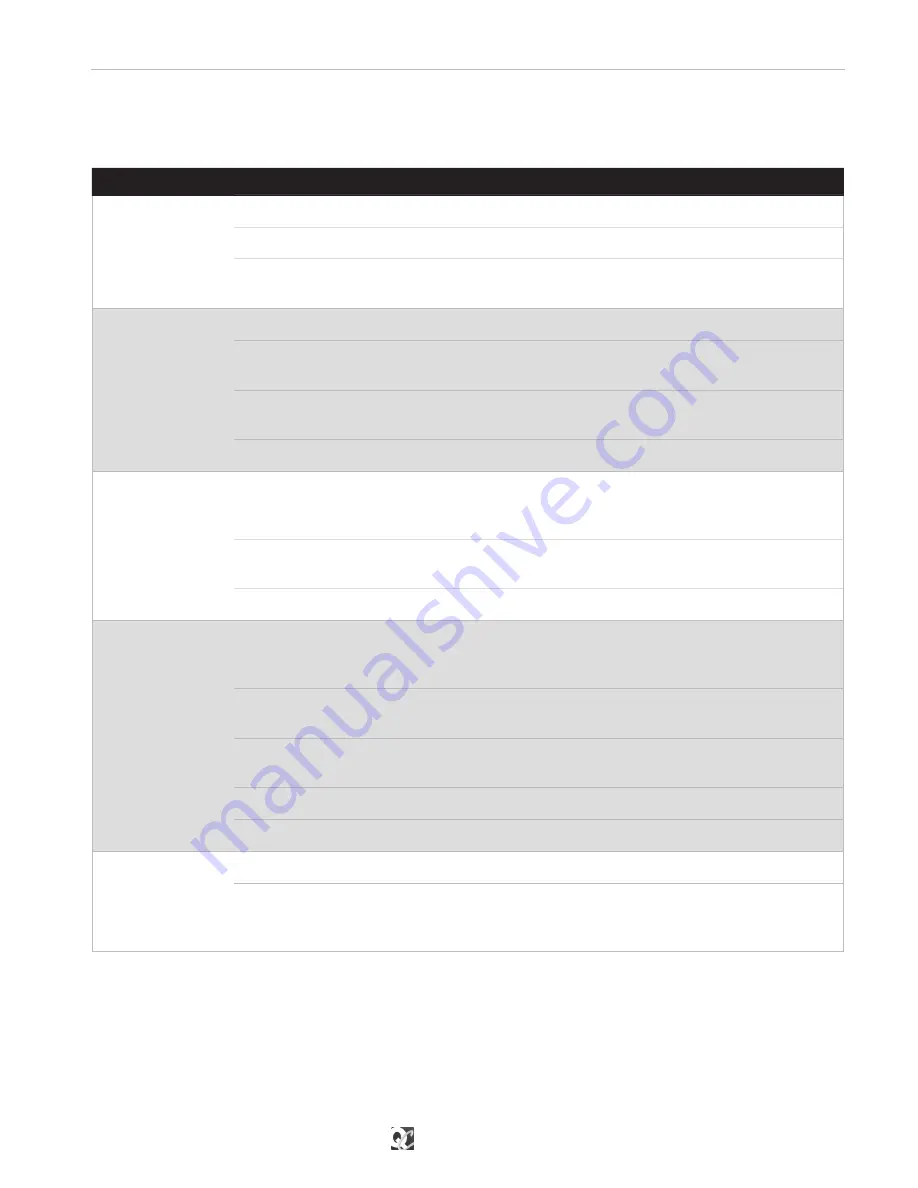

Symptom

Cause

Correction

Jerky Running

Damaged or badly fitted slide rail

Inspect and replace as necessary

Conveyor chain is too tight/loose

Tension conveyor chain correctly

Dirty conveyor

Clean conveyor chain and slide rail. Lubricate

with silicone based lubricant.

Noise

Worn or damaged bearings in drive unit

Check/replace drive unit

Damaged/badly fitted slide rail

Check that chain is free running, especially at

slide rail joints

Excessive conveyor speed

Lower speed. Check actual load against

recommended loading.

Incorrect conveyor chain tension

Tension conveyor chain correctly

Motor

overheating

on drive unit

Overloaded conveyor

Remove products from conveyor and

test. Check actual conveyor load against

recommended loading.

Gearbox leaking oil

Check output shaft seal and area around

motor/gearbox interface

Dirty conveyor

Clean the chain and slide rail

Abnormal

wear on

plastic parts

Overloaded conveyor

Remove products from conveyor and test.

Check that chain is free running. Check actual

conveyor load against recommended loading.

Ambient temperature too high

Check recommended temperature for

conveyor

Chemicals in the environment are affecting plastic

parts

Check Flextrac Series catalogue (section TR) for

listing of incompatible chemicals

Damage due to contamination

Clean the system

Particles, swarf etc.

Remove source of contamination

Drive unit

is running,

conveyor chain

is not moving

Friction disc in slip clutch is worn or contaminated

Check and replace if necessary

Transmission products are not fitted

Check and fit