21

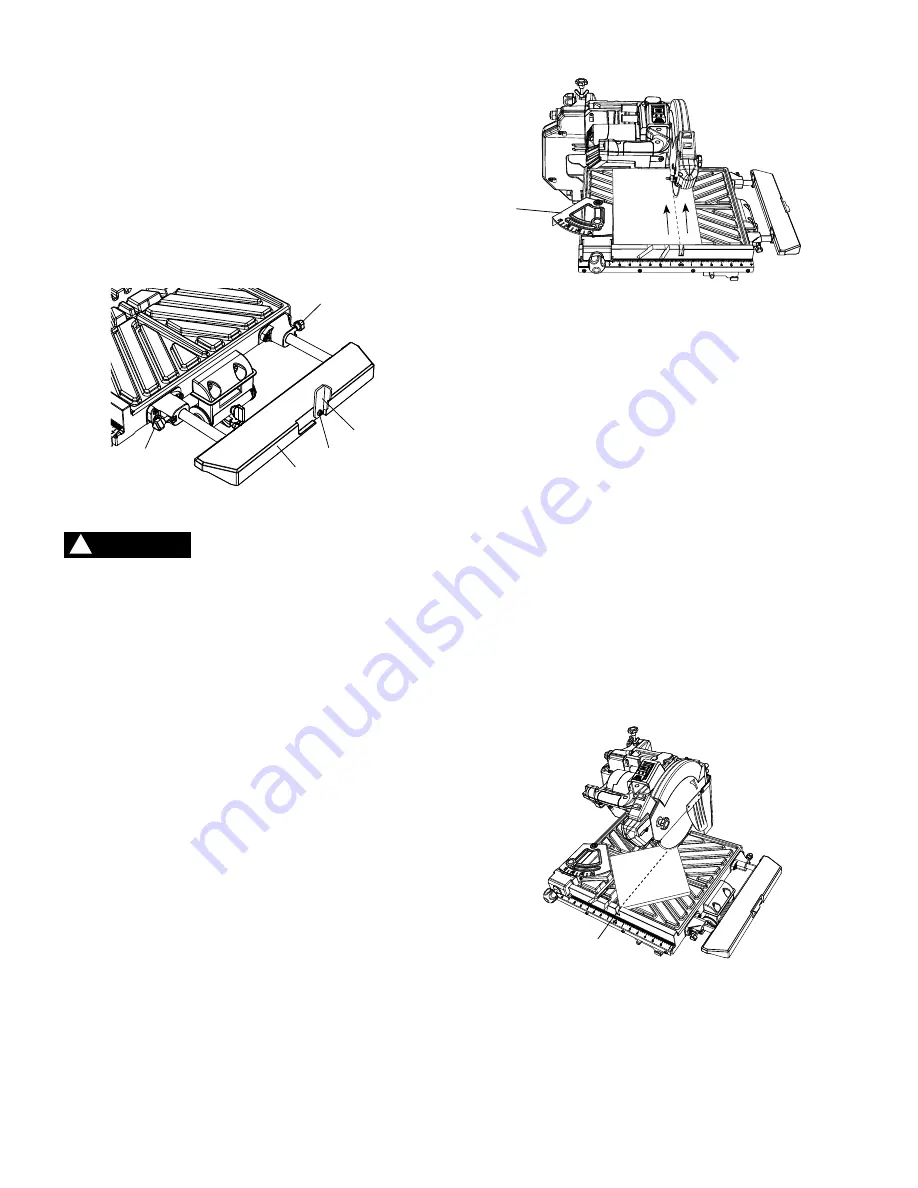

USING THe eXTeNSION TABLe, FOr SUppOrTING

LArGe FOrMAT TILe (FIG. LL)

•

Loosen the extension table locking knobs (1).

•

Pull the extension table (2) out to the desired

position. tighten the extension table locking

knobs (1).

•

the stop plate (3) is designed for repetitive cutting.

rotate the stop plate (3) to vertical position. if stop

plate will not rotate, loosen the locking screw (4) 1/4

turn.

CUTTING OPERATION

Before making any adjustments or removing or

installing attachments or accessories, make sure

the switch is in the OFF position to avoid injury

from an accidental start.

Before turning the tile cutter on, verify the alignment of

the cutting table and the cutting blade. always center

the cutting blade in one of the cutting table grooves

before cutting.

STrAIGHT CUT (FIG. MM)

•

using a pencil or marker mark the area to be cut on

tile.

•

Place the tile on the cutting table against the rip/

angle guide (1) and align the mark with the cutting

blade.

•

Pull the switch upward to turn the tile saw. allow the

cutting blade to reach full speed and wait until the

stream of water from the water nozzle completely

covers the cutting blade.

•

using both hands to slowly push the cutting table

toward the cutting blade to feed the tile into the

cutting blade (never force the material through the

blade. Move at a slow consistent pace).

•

turn the tile saw off once cut is performed.

2

1

1

3

4

Fig. LL

DIAGONAL CUT (FIG. NN)

NOTE:

diagonal cuts are also referred to as "long point

to point cuts."

•

using a pencil or marker mark the area to be cut on

tile.

•

align one point of the tile against the cut indicator (1)

of the cutting table. the cut indicator means the

exact location where the cutting blade will pass

through the cutting table.

•

align the front of the tile to the cutting blade and

hold against the rip/angle guide, which should be

adjusted to proper angle.

•

Pull the switch upward to turn the tile saw on to

allow the cutting blade at the full speed and wait

until the stream of water from the water nozzle

completely cover the cutting blade.

•

using both hands to slowly push the cutting table

toward the cutting blade to feed the tile into the

cutting blade.

•

turn the tile saw off.

WARNING

!

Fig. MM

Fig. NN

1

1

Summary of Contents for 900 XT PRO

Page 9: ...9 UNPACKING YOUR JOBSITE TILE SAW B C A D E F G H I J K L M N O P...

Page 25: ...25 PARTS LIST 900 XT PRO TILE SAW 61900Q...

Page 30: ...30 NOTES...

Page 31: ...31 NOTES...