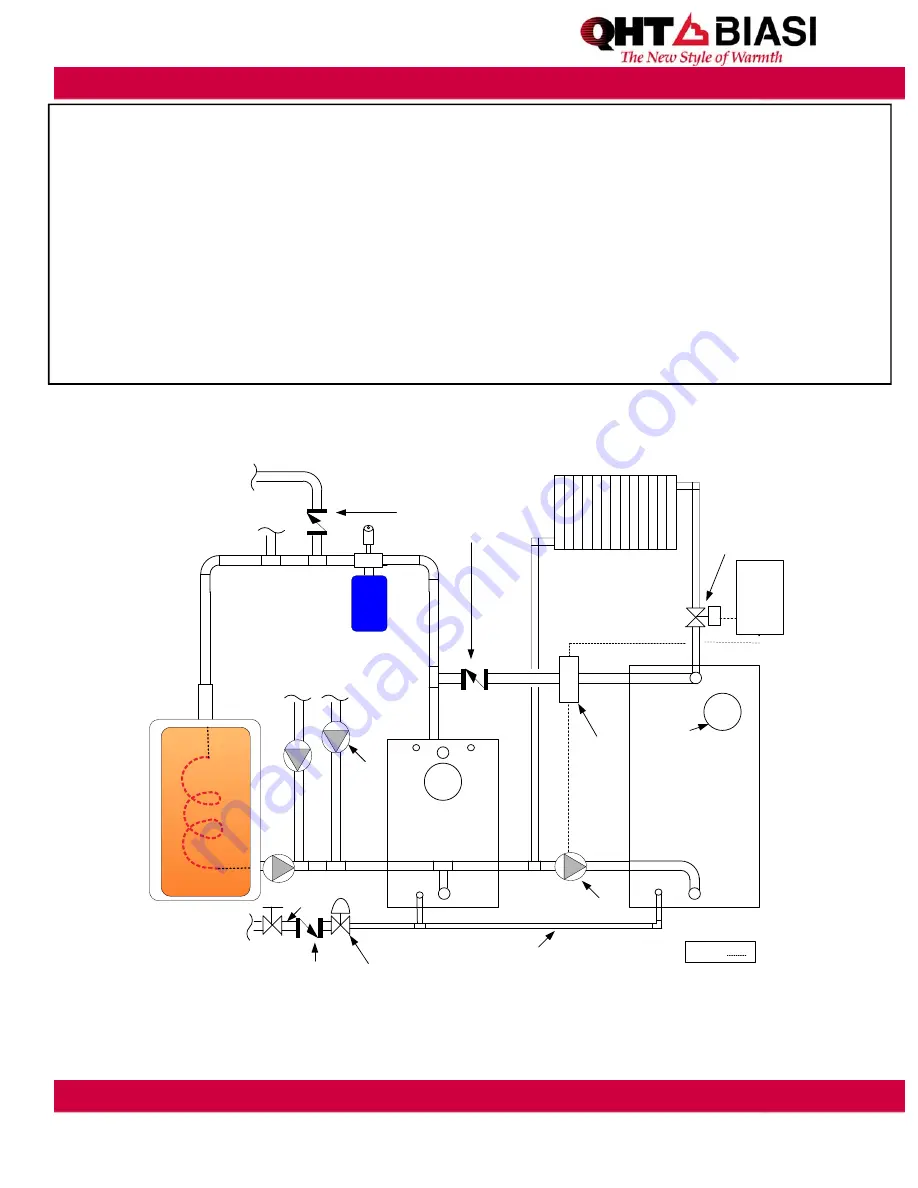

7

3WOOD Boiler

Oil/Gas Boiler

Auxiliary “Dump Zone” Utilizing Natural Thermal Circulation During Power Failure

7"Ø

Breach

Note: 3WOOD boiler

must be vented into

separate flue.

Increase Size of

Expansion Tank to

Accommodate 3WOOD

No Valves Installed on the

Radiator or Piping

Pressure

reducing

valve

Backflow

preventor

Water supply

Circ. A

Circ. B

[N.O.]

L4006B

Honeywell

Aquastat

180

°

F

Flow

Check

Flow

Check

½” Ø

¾ “ Ø

Wiring Legend

110 VAC

From

House

Service.

3WOOD Boiler piped in

parallel to Oil/ Gas Boiler

12,500 BTU/HR

Radiator to be

Installed above

the 3WOOD Boiler

110 VAC

N.O. 1" Ø

Zone Valve

DHW

Tank

In Event of

Power Failure

“OPEN CHECK

VALVES”

PROCEDURE IN EVENT OF POWER FAILURE

Should your electricity go off during the heating season, there are several procedures that should

be followed in order that you may continue to safely operate your heating system. These procedures

apply to the solid-fuel boiler, as the gas or oil-fired boiler, if any, will be completely inoperative.

1. Locate any “flow-check” valves in the system (See Pg. 7), and completely unscrew the knob on the

top of all these valves. (This will allow a certain amount of heated water to circulate by convection

throughout the house, preventing the pipes from freezing and keeping the house partially heated).

Note: This does not apply to gravity systems, as they have no flow-check

valves, and will continue to operate normally without electricity.

2. The automatic draft regulator will continue to control the wood fire in the absence of electric power. It

is important to remember that the heating system cannot dispose of a great deal of fuel without a

circulator running.

PIPING NOTES:

1. This drawing is meant to show system piping concept only. The installer is responsible for all equipment & detailing required by local

codes.

2. Discharge of Pressure Relief Valve must be piped without valves to within 3” of the floor.

3. Where required, Low Water Cutoff must be installed in the Supply piping of the oil/gas boiler