- 94 -

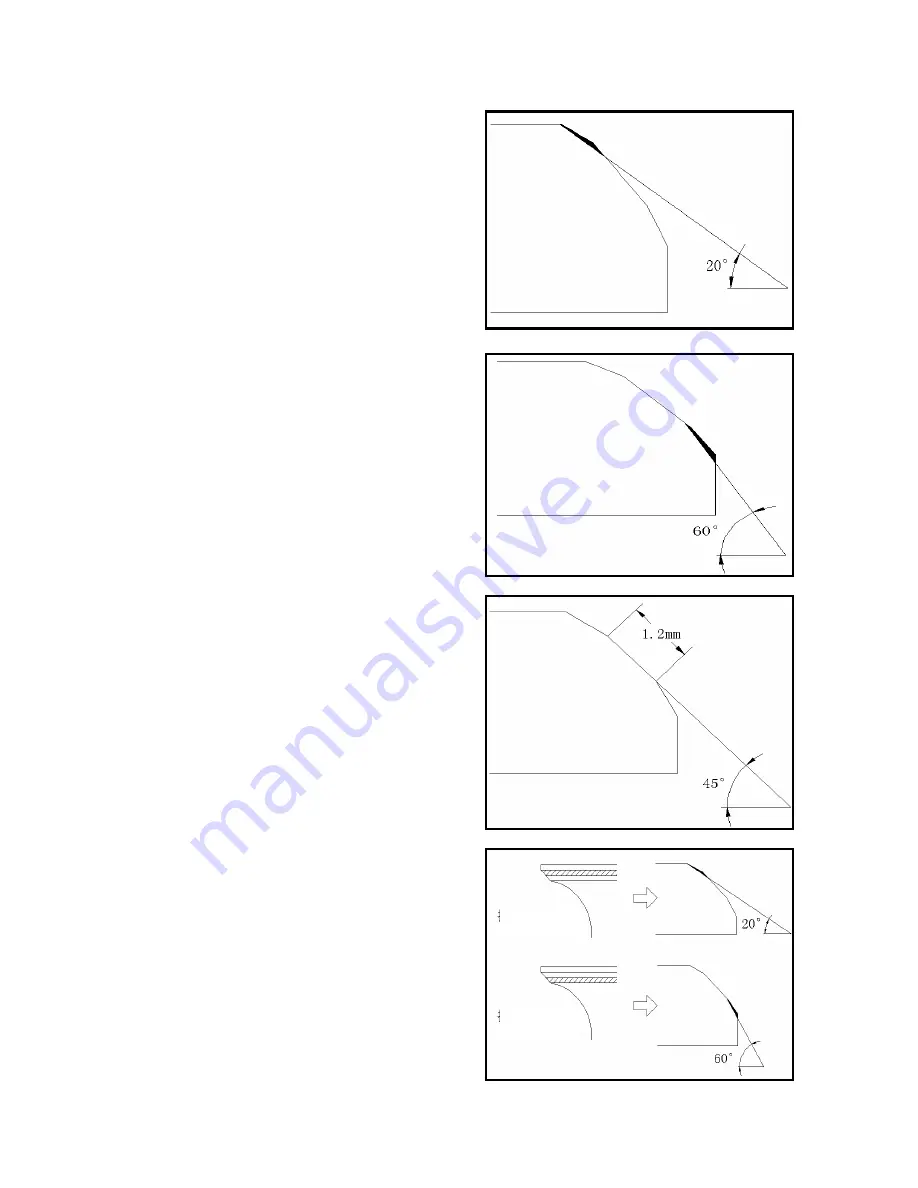

Remove 1/4 of the outer end of valve seat by using the

milling cutter of 20°.

Remove 1/4 of the bottom end of valve seat by using the

milling cutter of 60°.

Take down the milling cutter and examine the place which

is treated.

Grind the valve seat with the milling cutter of 45°to make it

with appropriate width. Make sure to remove all the dints

and uneven parts.

Standard width of valve seat: Inlet: 1.2m

Outlet

:

1.2m

If the contact part is the higher part of valve, use the plain

milling cutter of 20°to lower the valve seat.

If the contact part is the lower part of valve, use the internal

milling cutter of 60°to lower the valve seat.

Use the refining milling cutter of 45°to refine the valve seat

so as to make it fit the required specifications.

After finishing grinding the valve seat, paint the polishing

agent on the valve surface and gently polish the valve.

Contact part

is high

Contact part

is low

Summary of Contents for QJ150T-10

Page 15: ... 14 QJ150 10 ...

Page 73: ... 72 Rear wheel rear suspension ...

Page 78: ... 77 Lubrication system figure engine oil strainer oil pump bent axle camshaft piston ...

Page 87: ... 86 ...

Page 97: ... 96 ...

Page 104: ... 103 ...

Page 113: ... 112 Output axle Middle axle Input axle ...

Page 116: ... 115 The assembly of bearings and oil seal should use special tools to prevent damage ...

Page 125: ... 124 Muffler ...

Page 131: ... 130 ...