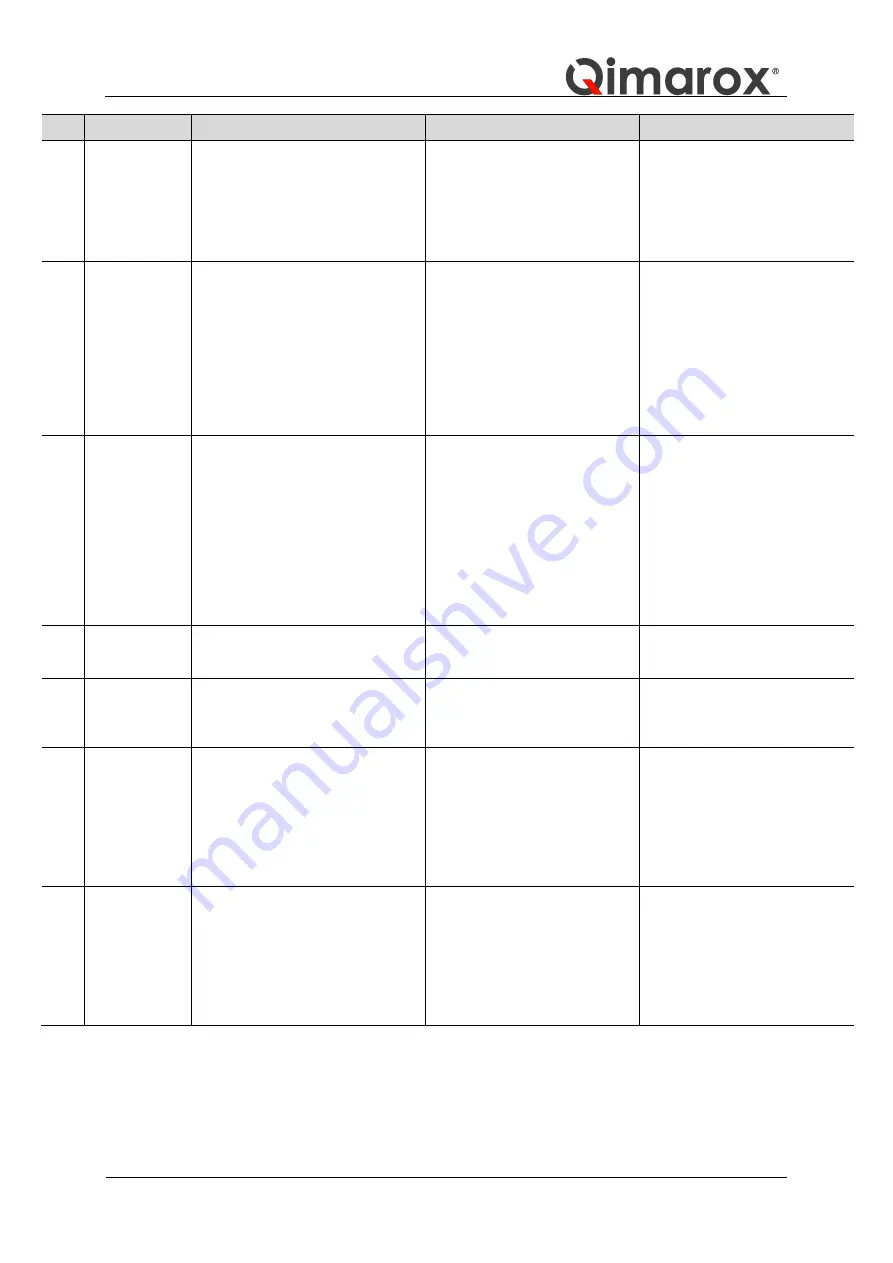

Notifications

138

Operating manual HR9

– QS21XXXX

No.

Action

Description

Cause

Solution

851

STOP

Palletlift; Mechanical locking

device not retracted

Pins to prevent lift from falling

down are not retracted

Sensors detecting successful

retraction are not triggered

Unit is stopped and quick stop

is generated to prevent any

damage

Check if air pressure if

available

Downwards movement of

palletlift has been blocked

Place unit in manual mode

Move palletlift up and reset

alarm.

852

STOP

Palletlift; Chain slack detected

Chain tension is not correct

Palletlift landed on a unknown

object

Unit is stopped and quick stop

is generated to prevent any

damage

Downwards movement of

palletlift has been blocked

Place unit in manual mode

Move palletlift up and reset

alarm.

Check for objects underneath

palletlift

Check bottom level sensor for

alignment and correct

operation

853

HOLD

Palletlift; Pallet height incorrect

Pallet height higher than

usual.

Bottom stop position triggered

while top stop position is still

blocked

Check why top level sensor is

no longer triggered

Check alignment and proper

operation

Validate actual number of

layers on palletlift with counted

layers

Use recovery menu to view

the counted layers.

Remove layers if pallet is to

high

854

SHOW

Palletlift; Pallet type incorrect

Incorrect pallettype present

Pallettype not matching

production settings

Pallet is rejected automatically

855

HOLD

Palletlift; Not on pallet infeed

position anymore, no detection

from sensor

Infeed sensor not triggered

anymore while palletlift

should be on infeed position

for empty pallet infeed

Check why sensor is no longer

triggered

Check alignment and correct

operation

856

HOLD

Palletlift; Timing error on sensor

top position (under

stackingplates), no row detected,

check situation on palletlift

Top stop position sensor was

unblocked to early while

moving down after drop-off of

layer.

Check if layer height is

correct.

Place unit in manual mode

Move palletlift down, and reset

alarm.

Validate top stop position

sensor for alignment and

proper operation

857

ABORT

Palletlift; Upper endswitch

reached

Maximum allowed position

reached

Unit is aborted and quick stop

is generated to prevent any

damage

Upwards movement of

palletlift has been blocked

Place unit in manual mode

Move palletlift down, and reset

alarm.

Validate top stop position

sensor for alignment and

proper operation