/&

4

4

*

c

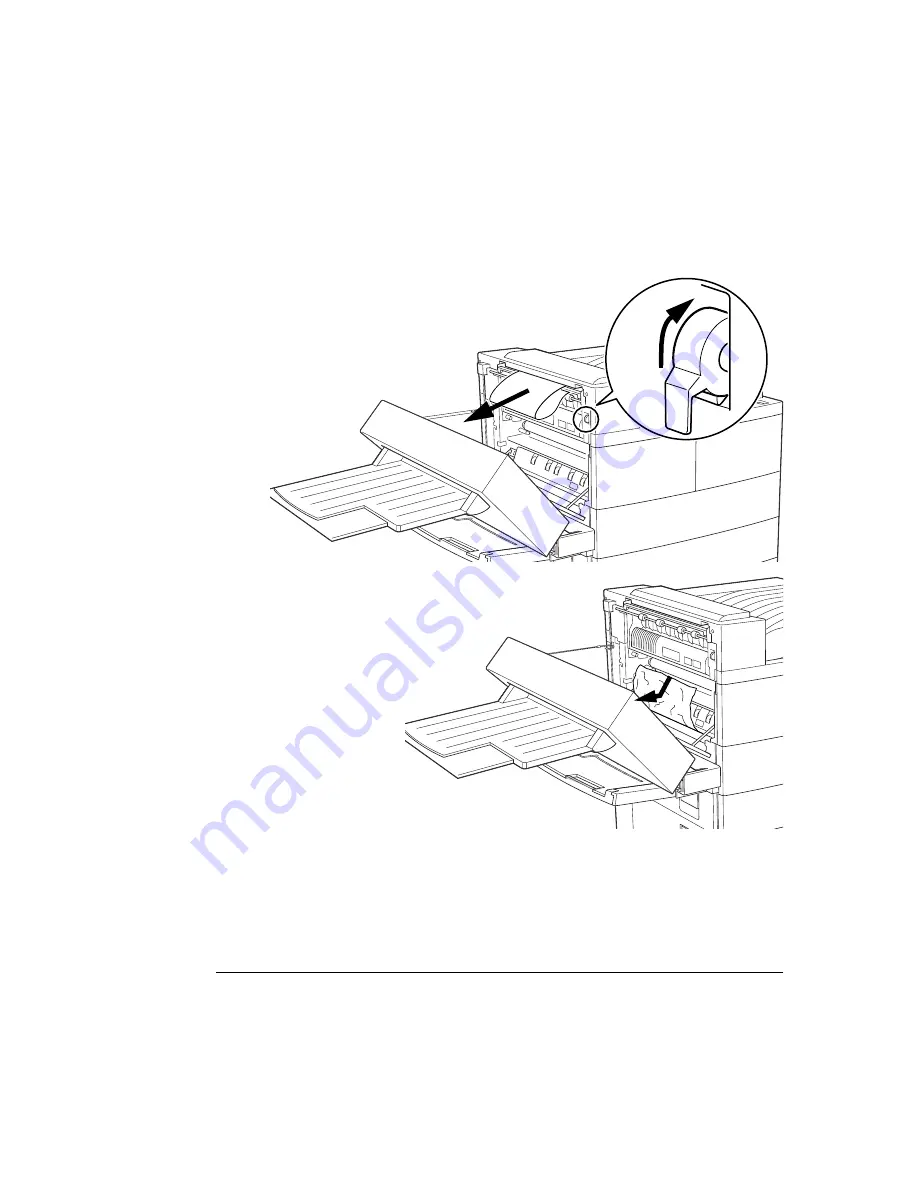

If it becomes difficult to pull out the media, lift the lever repeatedly in the

direction of the arrow until the media is accessible and easy to pull out.

d

If the media is

jammed below the

fuser, pull it out in

the direction of the

arrow.

▲

Caution:

Media that

hasn’t fully passed

through the fuser

contains unfused toner

that can dirty your

hands, clothes, or any

thing else it gets on. If

you accidentally get

toner on your hands,

wash them in cool

water. If you accidentally get toner on your clothes, lightly dust them off as much

as possible. If some toner remains on your clothes, use cool, not hot water, to

rinse the toner off, provided your clothing is washable.

4

Close the upper-left door and the duplexer.

5

Reattach the face-up tray.

Summary of Contents for 3260

Page 1: ......

Page 8: ......

Page 9: ...Introduction on page 1 2 About This Manual on page 1 2...

Page 12: ......

Page 39: ...2 Lift up the handles to unlock the transfer roller 3 Remove the transfer roller...

Page 46: ...1 Pull out the tray 6 2 Open the lower left door of the high capacity input feeder...

Page 48: ......

Page 87: ...2 3 2 1...

Page 90: ......

Page 106: ...4 5 8 1 Open the duplexer 2 Open the upper left door 3 Open the lower left door...

Page 111: ...4 4 5 8 1 Pull on the latch to open the duplexer 2 Open the cover inside of the duplexer...

Page 114: ...4 3 Reinsert the enve lope feeder...

Page 152: ......

Page 153: ...Sources of Support on page A 2 QMS World wide Offices on page A 4...

Page 184: ......

Page 194: ......