7URXEOHVKRRWLQJ

WKH7ULPPHU

4064'2&%RRNOHWPDNLQJ6\VWHP8VHU¶V*XLGH

&OHDULQJ3DSHU-DPV

»

Note:

When clearing a paper jam, try and remove all paper, without

tearing it. If the paper tears, inspect the paper path closely before

closing the QDOC Bookletmaking System. Small scrapes of paper

left in the paper path may not be sensed by the paper jam indicators.

If the printer experiences frequent paper jams, check thoroughly all

possible paper jam locations. If paper scraps remain in the system,

they may prevent the system from printing and you may have to call

for service. See “Placing a Service Call” on page 6-17, for information

on how to place a service call to your QMS vendor.

Paper jams can occur in the booklet input area and/or in the area

where a booklet enters the conveyor.

Use the following procedure to clear a Trimmer paper jam:

1

Place the Trimmer off line.

»

Note:

The Trimmer may have switched to off line mode

automatically when it detected a paper jam.

2

Open the top cover.

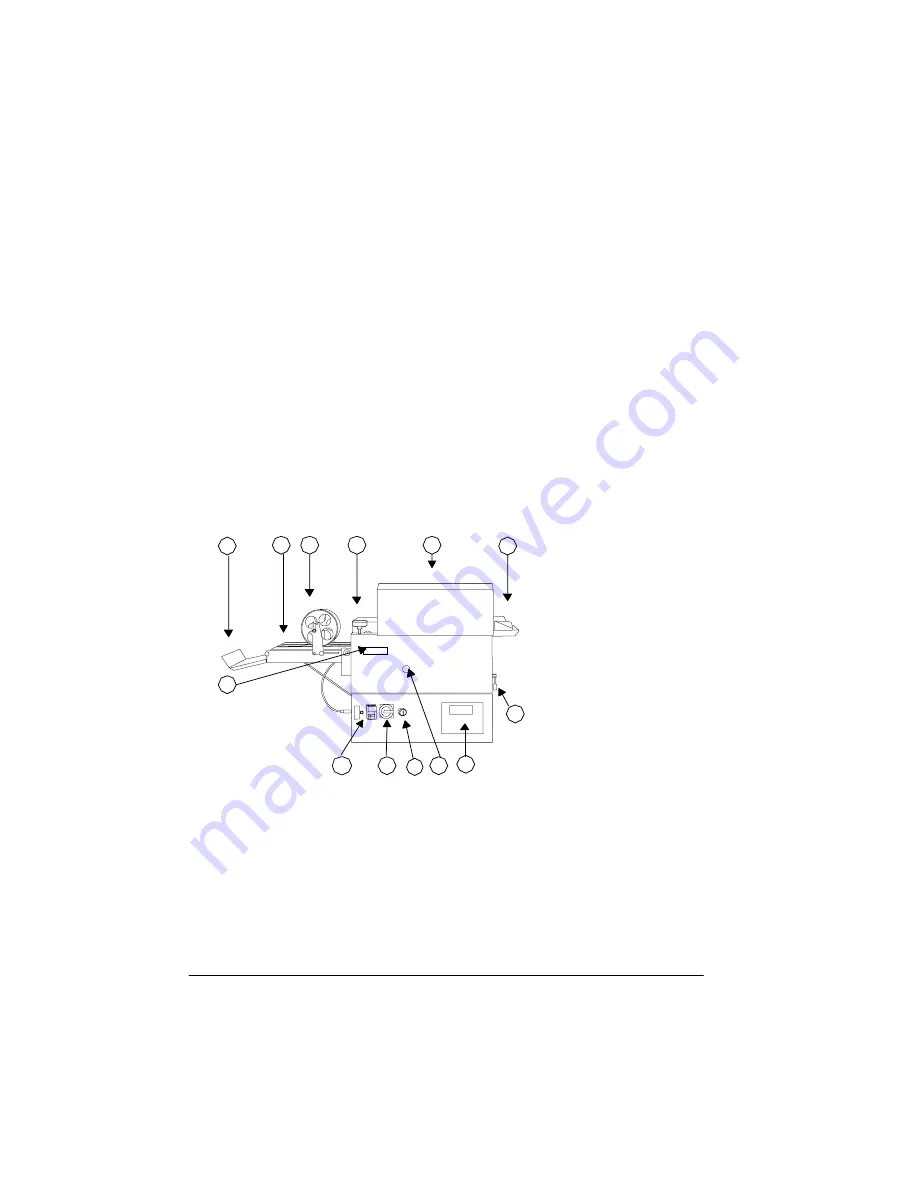

%RRNOHWLQSXW

7RSFRYHU

6HUYLFHZKHHO

&RQYH\RUZKHHO

&RQYH\RU

%RRNOHWFROOHFWRU

&RQWUROSDQHO

6HUYLFHVZLWFKHV

0DLQSRZHUVZLWFK

6HUYLFHDGMXVWPHQW

:DVWHWUD\

+DQGOHWR)ROGHU

6WDSOHU

5HVHW%XWWRQ

Summary of Contents for QDOC

Page 1: ...k k 3 k bk p p...

Page 9: ...QWURGXFWLRQ Q 7KLV KDSWHU Introduction on page 1 2 Standard Product Documentation on page 1 5...

Page 32: ......

Page 46: ......

Page 122: ......

Page 140: ......

Page 141: ...2SWLRQV Q 7KLV KDSWHU Introduction on page 7 2 Stapler Head on page 7 2...

Page 143: ...6WDSOHU HDG 2SWLRQV 3 Open the cover RYHU...

Page 154: ......

Page 172: ......