6

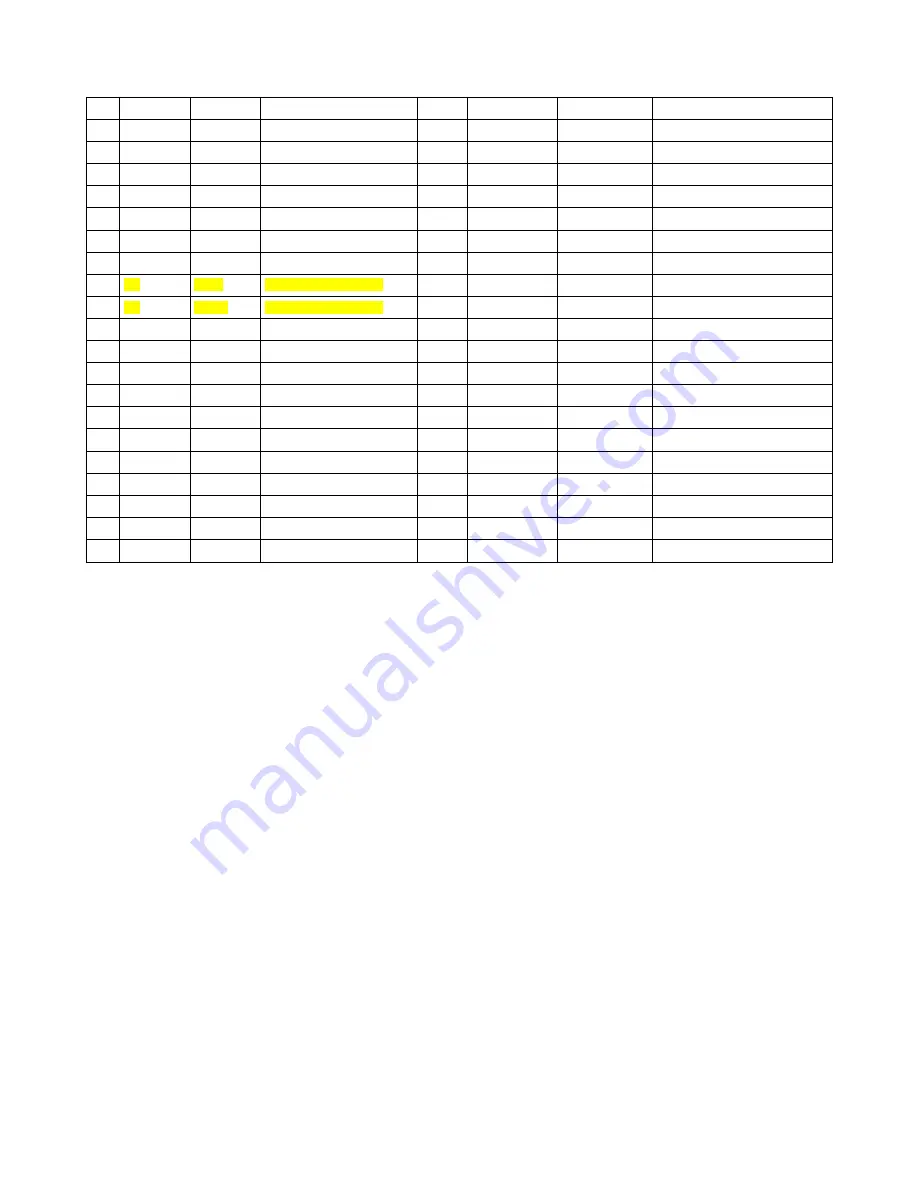

Part by part placement guide:

Resistors

√

location

Value

Color code

√

Location

Value

Color code

R1

100 K

BRN/BLK/YEL/GLD

R21

270

Ω

RED/VOL/BRN/GLD

R2

47 K

YEL/VOL/ORG/GLD

R22

270

Ω

RED/VOL/BRN/GLD

R3

51

Ω

GRN/BRN/BLK/GLD

R23

1 MEG

BRN/BLK/GRN/GLD

R4

100 K

BRN/BLK/YEL/GLD

R24

1 K

BRN/BLK/RED/GLD

R5

270

Ω

RED/VOL/BRN/GLD

R25

2.2 K

RED/RED/RED/GLD

R6

270

Ω

RED/VOL/BRN/GLD

R26

1 MEG

BRN/BLK/GRN/GLD

R7

470

Ω

YEL/VOL/BRN/GLD

R27

1 K

BRN/BLK/RED/GLD

R8

3.9 K

SMT PREINSTALLED

R28

2.2 K

RED/RED/RED/GLD

R9

270

Ω

SMT PREINSTALLED

R29

1 K

BRN/BLK/RED/GLD

R10

270

Ω

RED/VOL/BRN/GLD

R30

2.2 K

RED/RED/RED/GLD

R11

2.2 K

RED/RED/RED/GLD

R31

22 K

RED/RED/ORG/GLD

R12

22 K

RED/RED/ORG/GLD

R32

2.2 K

RED/RED/RED/GLD

R13

220 K

RED/RED/YEL/GLD

R33

2.2 K

RED/RED/RED/GLD

R14

2.2 K

RED/RED/RED/GLD

R34

2.2 K

RED/RED/RED/GLD

R15

470 K

YEL/VOL/YEL/GLD

R35

2.2 K

RED/RED/RED/GLD

R16

10 K

BRN/BLK/ORG/GLD

R36

2.2 K

RED/RED/RED/GLD

R17

1 MEG

BRN/BLK/GRN/GLD

R37

2.2 K

RED/RED/RED/GLD

R18

220 K

RED/RED/YEL/GLD

R38

2.2 K

RED/RED/RED/GLD

R19

470 K

YEL/VOL/YEL/GLD

R39

2.2 K

RED/RED/RED/GLD

R20

10 K

BRN/BLK/ORG/GLD

R40

10

BRN/BLK/BLK/GLD

Molded inductors:

There are four (4) molded inductors (RFC) to install. These look like resistors but are a little shorter and fatter. Like resistors, the value is also

color coded on the body of the part.

•

Install L3/L4 – 3.3 uhy ORN/ORN/GLD/GLD

•

Install L6/L7 – 10 uhy BRN/BLK/BLK/GLD

Diodes: Be sure to observe proper polarity. Band near end of part goes towards line on part outline.

•

Install D1 – 1N5817 large plastic body.

•

Install D2 – 1 N4756A large glass body

•

Install D3/D4/D5 – 1N4148 small glass body

Crystals:

The crystals are now installed, the locations are shown filled in with light gray. All the crystals are matched and the same frequency, so it

doesn't matter which ones go where. The cans of the X1 to X4 crystals should be tack soldered to the solder pad located next the the body

of the crystal. This should be done now, as getting an iron in after the near-by capacitors are installed will be difficult.

•

Install X1 to X5

IC sockets:

IC sockets are now installed. Before soldering, make sure they are flush to the board and that all the pins are sticking out of the holes on the

bottom of the board. If a pin gets bent over as you are inserting the socket, this will be difficult to fix once the other pins have been soldered.

•

U3, U4, U6, U9 – 8 pin socket

•

U2 – 14 pin socket

•

U7 – 28 pin socket