28

ELECTRICAL RETRACTORS INSTALLATION

o

Electrical Retractors are designed and tested to ONLY be used in the front positions together with Q’Straint® 4-Point

Securement Systems.

o

Mounted Electrical Retractors MUST be clear of any obstructions and in an area where they can not be damaged due to

moving passengers or any transported goods within the vehicle.

o

Electrical Retractors MUST be mounted in a horizontal plane to ensure that the webbing does not jam or at a 30 degree

angle using Q’Straint® Bracket (part # Q8-6510).

o

When the Electrical Retractors are fitted into the vehicle’s electrical system, they must be suitably fused, switched,

grounded and a compatible wire gage MUST be used. As well as the proper protection of the wires from dirt and

moisture.

o

When the Electrical Retractors are correctly fitted and wired, they will restrain a maximum of 15kN (3,300lbs) frontal

rebound force and can be locked and unlocked as follows:

•

Power On = retractors are released, webbing moves in and out of retractor.

•

Power Off = retractors are locked, webbing will not come out, but it will self-retract.

INSTALLATION CHECKLIST

ELECTRICAL REQUIREMENTS

•

The Electrical Retractors MUST be connected to the vehicle’s electrical system.

• 12VDC 1.5 amps

• Compatible with all 12 Volt vehicles.

ELECTRICAL RETRACTOR FAIL-SAFE SYSTEM REQUIREMENTS

• Vehicle must come to a complete stop and parking brake applied, then connect 12VDC power to Electric Retractors.

• All systems require a 12 VDC connected to the Electric Retractors and isolated through an Electrical Switch.

• The two wire connectors need to be placed near the Electrical Retractors and properly secured, covered and protected from the elements.

• Voltage to the Electric Retractors can only be initiated through the activation of the Electrical Switch.

• All systems require a second switch that de-energizes the relay by removing voltage from the Electrical Retractors.

• In addition to these manual controls, the Electric Retractor installation MUST be equipped with fail-safes that help prevent Electric

Retractors from being released while the vehicle is moving.

• One or more of the following examples are recommended, and must be used:

1. An electric timer that cuts the voltage to the Electrical Retractors within a 2 minute window of their activation.

2. A tailgate, door or ramp switch that removes voltage to the Electrical Retractors when the tailgate or ramp door is closed

and the ramp is stowed.

3. A parking brake switch that removes voltage to Electrical Retractors when the parking brake is released.

4. A transmission switch that removes voltage to Electrical Retractors when transmission is out of park.

5. A warning light that illuminates when the 12 volts is applied to the Electrical Retractors—

this is not a fail-safe, only a visual warning.

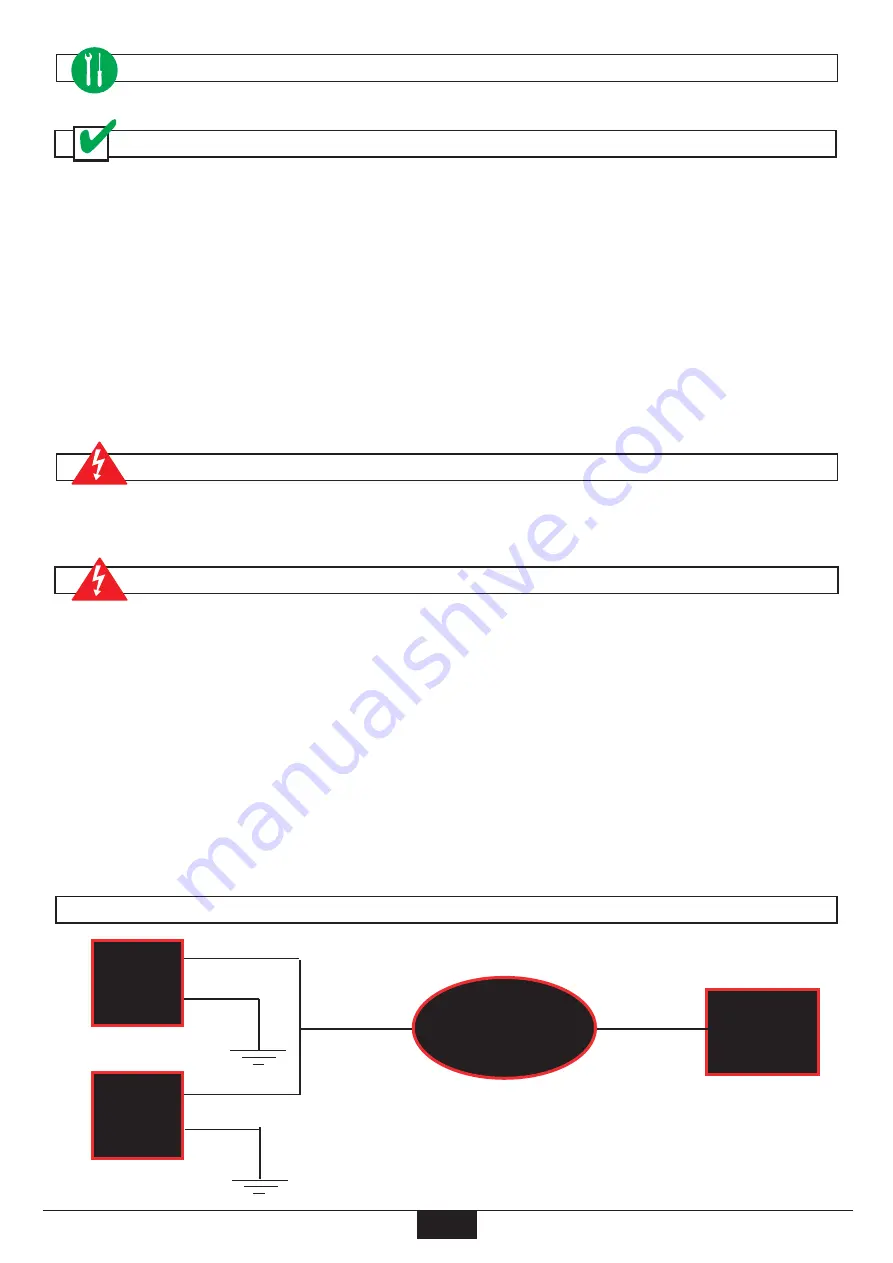

Retractor 2

VBATT

12Vdc

Required

Fail-Safe

Controls

RED

BLK

RED

BLK

Retractor 1

ELECTRICAL LAYOUT