9

QLK INSTALLATION

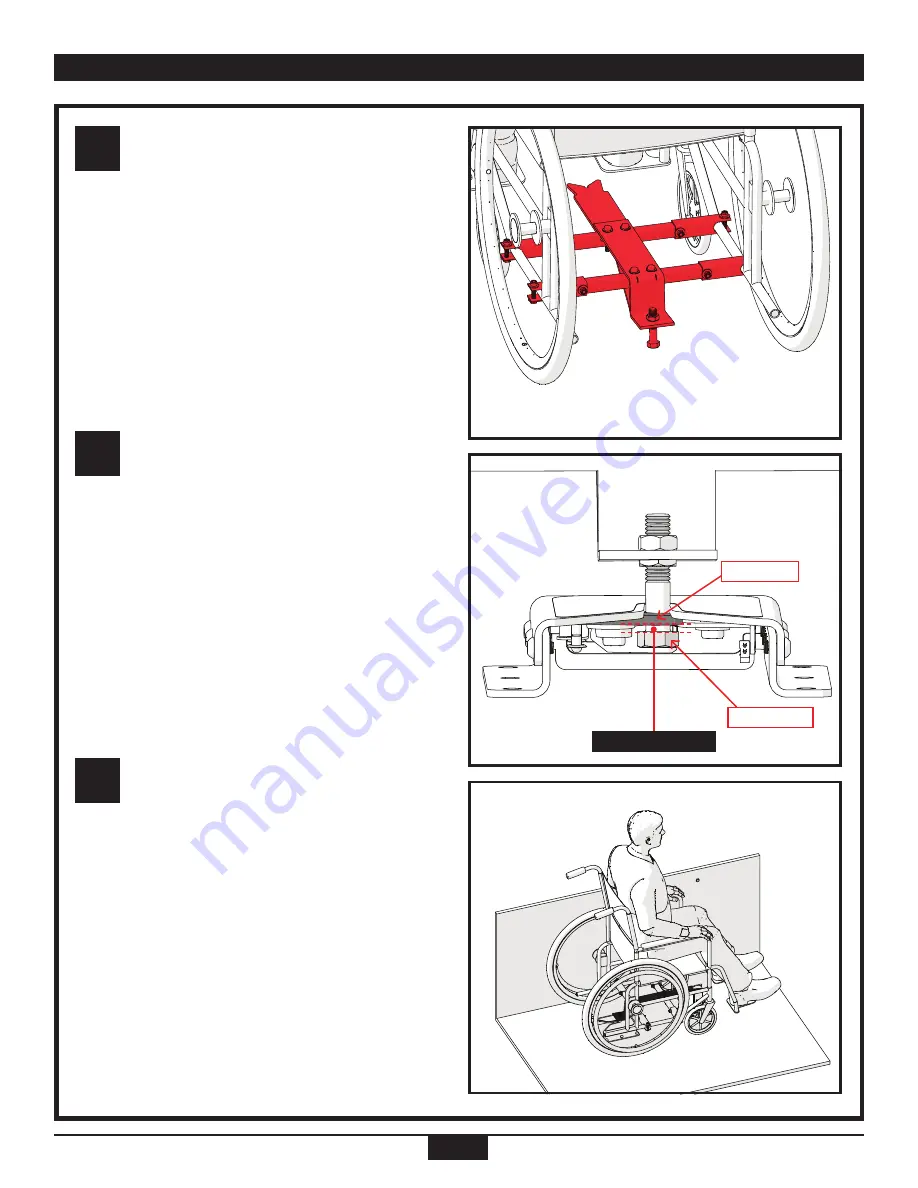

Install Wheelchair Bracket Interface

Follow the installation instructions that come with the

bracket. This will vary depending on the wheelchair

model.

Align height of bolt with height of QLK

Docking Station

Use a flat head screwdriver to ensure the proper gap

between the head of the bolt and the locking pawl.

Optimize Wheelchair Location!

The Wheelchair should be located to allow for

proper access to the wheelchair space. Remove any

obstructions from the rear, front, left and right of the

wheelchair that may prevent the QLK Docking Station

from properly securing the wheelchair.

Max Distance .125”

Locking Pawl

Head of Bolt

3.

2.

1.