17

DISCONNECT AIR SUPPLY BEFORE SERVICING. THE CLAMPING AND FEED MECHANISMS ARE

EXPOSED.TO AVOID INJURY, KEEP FINGERS AND HANDS AWAY FROM THESE AREAS WHEN

HANDLING OR OPERATING TOOLS.

WARNING

!

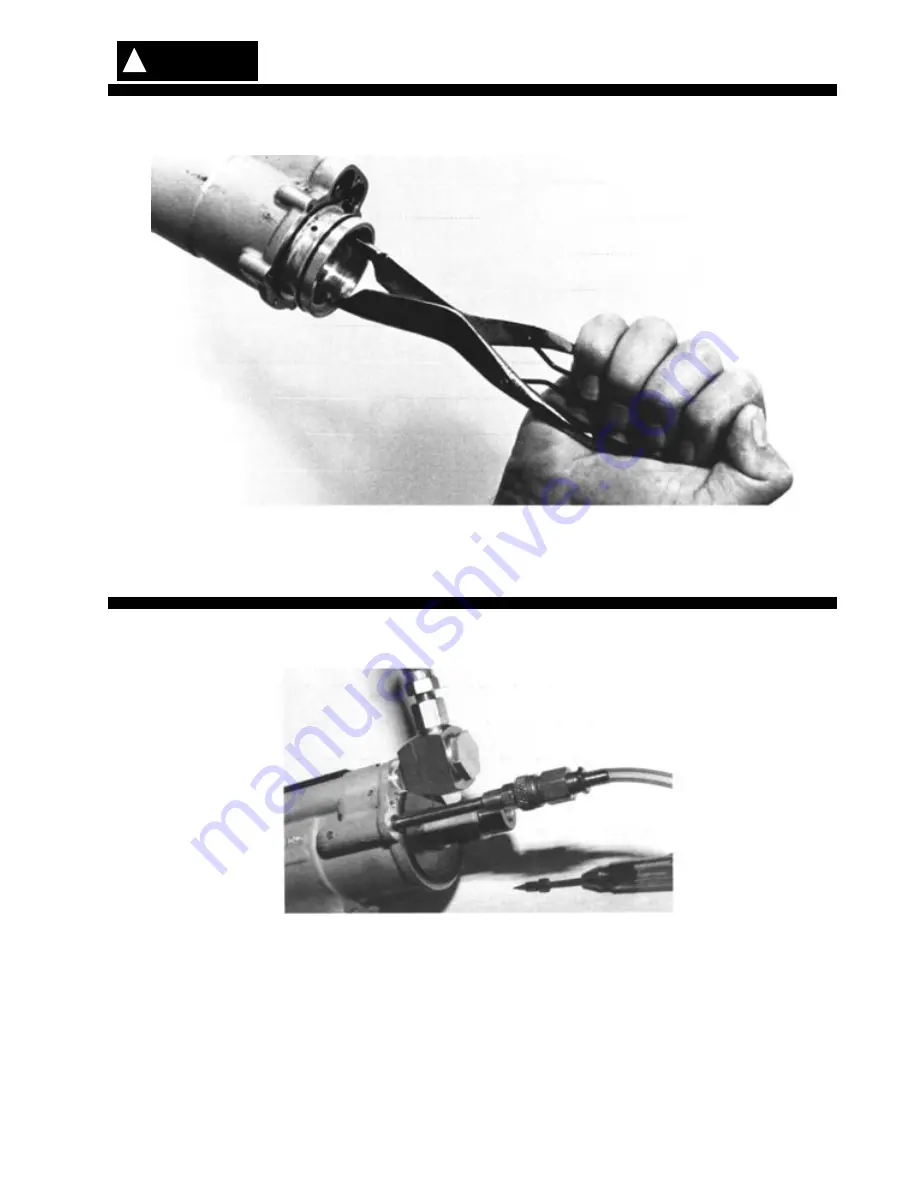

3. Rear bearing support is removed by tapping the motor housing on cushioned bench top.

The rear bearing support can also be removed using special internal grip pliers as shown in

photo.

Hydraulic System Bleeding and Filling Procedure

Air Motor Assembly Removal — continued

Attach hydraulic bleed unit to hydraulic fill fitting using hydraulic fitting coupler 622871. Remove

feed control needle valve 622026 and screw in circulating line. Attach air line to tool and turn

on air. Turn on circulating pump to circulate fluid. Depress trigger on tool several times to

remove air. Visually check circulating line for air bubbles. Check fluid indicator to see if tool is

full of fluid. Turn off circulating pump and disconnect hydraulic fitting coupler 622871 NOTE:

Do not damage spindles when disconnecting coupler. Disconnect circulating line and replace

feed control needle valve 622026. NOTE: If tool "lunges" during operation, it is due to trapped

air. Repeat bleed procedure described above.