Page 16

7039-131H

May 5, 2011

R

2100 Millennium Wood Stove (ACC)

Chimney Height / Rise and Run

This product was designed for and tested on a 6 inch (152mm)

chimney, 14 to 16 feet (420-480cm) high, (includes stove

height) measured from the base of the appliance. The further

your stack height or diameter varies from this configuration,

the possibility of performance problems exists.

Chimney height may need to be increased by 2 - 3% per

each 1000 feet above sea level. It is not recommended to

use offsets or elbows at altitudes above 4000 feet above sea

level or when there are other factors that affect flue draft.

C. Installing Chimney Components

Chimney Connector

Single wall connector or stove pipe.

This must be at least 24 gauge mild steel or 26 gauge blue

steel. The sections must be attached to the appliance and to

each other with the crimped (male) end pointing toward the

stove. All joints, including the connection at the flue collar,

should be secured with 3 sheet metal screws. Make sure

to follow the minimum clearances to combustibles. Where

passage through the wall, or partition of combustible con-

struction is desired in Canada, the installation shall conform

to CAN/CSA-B365.

Factory-built listed chimney connector (vented).

A listed connector (vented) must be used when installing this

unit in a mobile home. The listed connectors must conform

to each other to ensure a proper fit and seal.

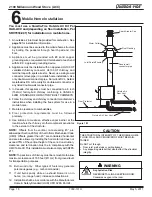

Flue Gas

Direction

Crimped

End

Toward

Stove

Secure pipe sections with a

minimum of 3 screws

Figure 16.2 Chimney Connector (Stove Pipe)

WARNING

• DO NOT CONNECT THIS UNIT TO A CHIM-

NEY FLUE SERVICING ANOTHER APPLI-

ANCE.

• DO NOT CONNECT TO ANY AIR DISTRI-

BUTION DUCT OR SYSTEM.

May allow flue gases to enter the house.

Asphyxiation Risk.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer

to the owner’s information manual provided with this appli-

ance. For assistance or additional information consult a

qualified installer, service agency or your dealer.

WARNING

Fire Risk

.

Inspection of Chimney:

• Chimney must be in good condition.

• Meets minimum standard of NFPA 211

• Factory-built chimney must be 6 inch

(152mm) UL103 HT.

WARNING

WARNING

ONLY use connector:

• Within the room, between appliance and ceiling or wall.

Connector shall NOT pass through:

• Attic or roof space

• Closet or similar concealed space

• Floor or ceiling

Maintain minimum clearances to combustibles

Fire Risk.

Follow Chimney Connector Manufacturer’s

Instructions for Proper Installation.

Chimney Flue

Liner

Fireclay

Liner or

Equivalent

Masonry Chimney

Constructed to NFPA 211

Wall Spacer

Wall Band

Trim Collar

Chimney

Connector

1 inch (25mm) Air

Space to Chimney

Section

Min. Clearance

2 inch (51mm)

Min. Chimney Clearance to

Wall Spacer and

Combustibles - 2 inch (51mm)

Chimney Section

Figure 16.1

Solid Pack Chimney with Metal Supports as a

Thimble (Cont’d)

Summary of Contents for 21M-ACC

Page 40: ...Page 40 7039 131H May 5 2011 R 2100 Millennium Wood Stove ACC D Homeowner s Notes...

Page 41: ...May 5 2011 7039 131H Page 41 2100 Millennium Wood Stove ACC R D Homeowner s Notes...

Page 42: ...Page 42 7039 131H May 5 2011 R 2100 Millennium Wood Stove ACC E Warranty Policy...

Page 43: ...May 5 2011 7039 131H Page 43 2100 Millennium Wood Stove ACC R...