May 14, 2015

7046-192C

3

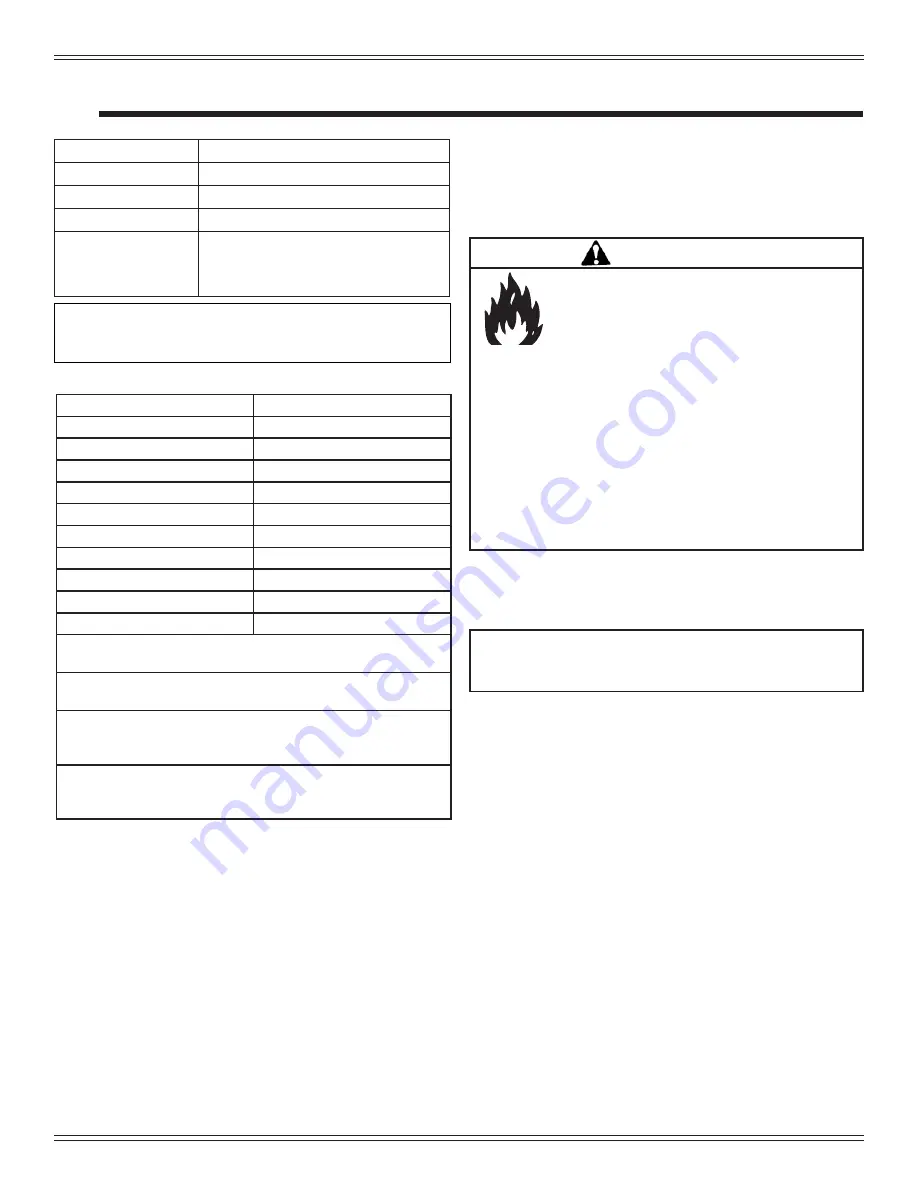

2700 I-ACC

Model:

2700-I (ACC) Insert

Laboratory:

OMNI Test Laboraties, Inc.

Report No:

061-S-78-6.2

Type:

Solid Fuel Type, Listed Room Heater

Standard:

UL1482-1996 (RR2006) and ULC

S628-93 and (UM) 84-HUD, Mobile

Home Approved.

EPA Certifi cation #: 649

EPA Certifi ed Emissions: 1.10 grams per hour

*EPA Default Effi ciency: 63%

**Actual Tested Effi ciency: 78.7%

***EPA BTU Output: 11,800 to 32,900 / hr.

****Peak BTU/Hour Output: 51,100

Vent Size: 6 inches

Firebox Size: 1.85 cubic feet

Maximum Wood Length: 18 inches

Ideal Wood Length: 16 inches

Fuel Seasoned Cord Wood

*

An effi ciency based on EPA historical data: 63% for non-cata-

lytic stoves.

**

Maximum calculated effi ciency using Douglas Fir dimensional

lumber and data collected during EPA emissions test.

***

A range of BTU outputs based on EPA Default Effi ciency and

the burn rates from the low and high EPA tests, using Douglas

Fir dimensional lumber.

****

A peak BTU out of the unit calculated using the maximum fi rst

hour burn rate from the High EPA Test and the BTU content of

cordwood (8600) times the effi ciency.

The Quadra-Fire 2700 Series Wood Insert (ACC) meets the

U.S. Environmental Protection Agency’s crib wood emission

limits for wood heaters sold after May 15, 2015.

1

Important Safety Information

A. Insert Certifi cation

NOTE: Hearth & Home Technologies, manufacturer of

this appliance, reserves the right to alter its products, their

specifi cations and/or price without notice.

C. Mobile Home Approved

•

This appliance is approved for mobile home installa-

tions when not installed in a sleeping room and when

an outside combustion air inlet is provided.

•

The structural integrity of the mobile home fl oor, ceil-

ing, and walls must be maintained.

•

The appliance must be properly grounded to the frame

of the mobile home with #8 copper ground wire, and

chimney must be listed to UL103 HT or a listed UL-

1777 full length six inch (152mm) diameter liner must

be used.

•

Outside Air Kit, part OAK-ACC must be installed in a

mobile home installation.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage.

For assistance or additional information, consult a qualifi ed

installer, service agency or your dealer.

Quadra-Fire is a registered trademark of Hearth & Home

Technologies.

• Installation and use of any damaged appliance.

• Modifi cation of the appliance.

• Installation other than as instructed by Hearth & Home

Technologies.

• Installation and/or use of any component part not approved by

Hearth & Home Technologies.

• Operating appliance without fully assembling all components.

• Operating appliance without legs attached (if supplied with unit).

• Do NOT Overfi re - If appliance or chimney connector glows, you

are overfi ring.

Any such action that may cause a fi re hazard.

WARNING

Fire Risk.

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be voided

by, the following actions:

B. BTU & Effi ciency Specifi cations

D. Glass Specifi cations

This stove is equipped with 5mm ceramic glass. Replace

glass only with 5mm ceramic glass. Please contact your

dealer for replacement glass.

Hearth & Home Technologies WILL NOT warranty stoves

that exhibit evidence of over-fi ring. Evidence of over-fi ring

includes, but is not limited to:

• Warped air tube

• Deteriorated refractory brick retainers

• Deteriorated

baffl e and other interior components

E. Non-Combustible Materials

Material which will not ignite and burn, composed of any

combination of the following:

-

Steel

-

Plaster

-

Brick

-

Iron

-

Concrete

-

Tile

-

Glass

-

Slate

Materials reported as passing

ASTM E 136, Standard

Test Method for Behavior of Metals, in a Vertical Tube

Furnace of 750° C.

F. Combustible Materials

Material made of/or surfaced with any of the following ma-

terials:

-

Wood

-

Compressed

Paper

- Plant Fibers

- Plastic

- Plywood/OSB

- Sheet Rock (drywall)

Any material that can ignite and burn: fl ame proofed or not,

plastered or un-plastered.

NOTE: This installation must conform with local codes. In the

absence of local codes you must comply with the UL1482, (UM)

84-HUD and NPFA211 in the U.S.A. and the ULC S628-93 and

CAN/CSA-B365 Installation Codes in Canada.