3100 ACT Wood Stove Series

Page 16

250-6103C December 6, 2004

R

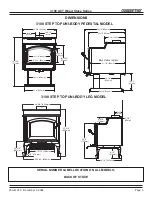

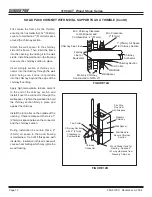

PEDESTAL MODEL

1 Place protective pad or stove pallet on floor.

2. Lay body of stove on its back on protective pad or

pallet.

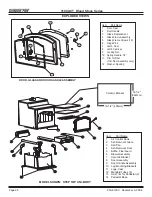

3. Loosen screws on adapter and slide pedestal over

adapter on bottom of stove

4. Line up holes in sides of pedestal with holes in

adapter.

5. Securely tighten pedestal into place.

6. Carefully stand stove up and place in desired loca-

tion.

7. Slip wooden decorative strips onto pedestal edges.

8. Open door of stove and check to make sure firebricks

and ceramic blanket are in their proper locations

(see

pages 23-24)

.

PEDESTAL OR LEG KIT INSTALLATION

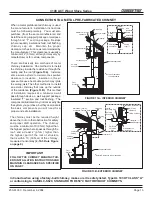

LEG MODEL

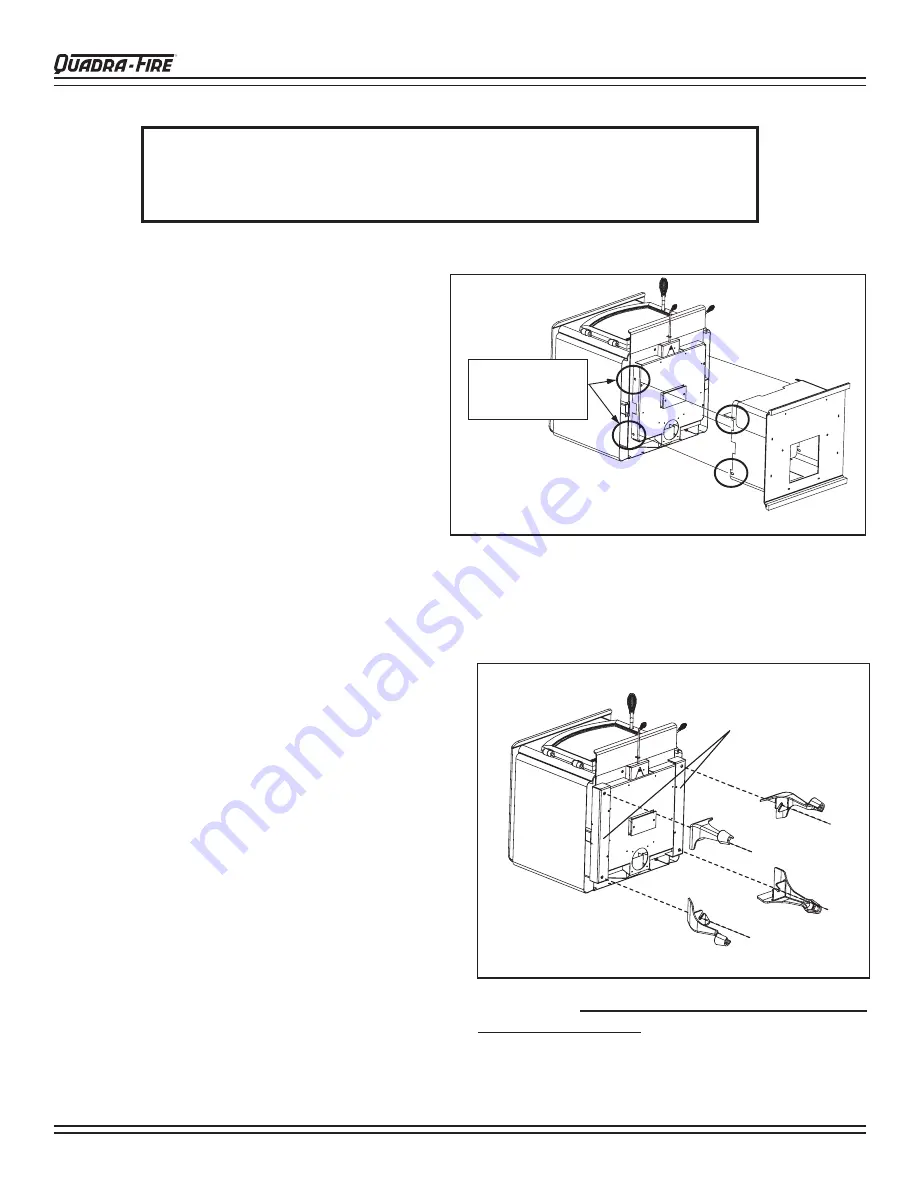

1. Remove leg mounting brackets packaged inside fire-

box.

2. Place protective pad or stove pallet on floor.

3. Lay body of stove on its back on protective pad or

pallet.

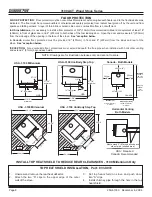

4 Remove the bolts, using a 9/16” Hex Head socket or

wrench, from the adapter and save.

5. Secure mounting brackets to the bottom of the stove

with 1/4”-20 Phillips screws. These screws are located

on the outer skin at the bottom rear of the stove.

See

Figure 16A.

6. Loosely assembly bolts into the corner of the mounting

brackets.

7. Slide legs onto mounting brackets and tighten.

8. Carefully stand stove up and place in desired location.

9. Use leveling bolts on legs to stabilize and level stove.

10. Open door of stove and check to make sure firebricks

and ceramic blanket are in their proper locations

(see

pages 23-24).

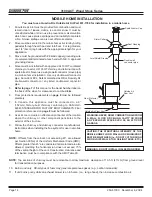

If installing legs, remove

these screws to attach

leg brackets to bottom

of stove

LEG MOUNTING BRACKETS

(packaged inside stove firebox).

CAUTION! DO NOT TILT THE UNIT ON THE

CAST IRON LEGS. Lift the unit upright and

place it into position on the floor protector.

Figure 16A

Figure 16B

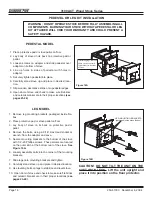

WARNING: DO NOT OPERATE STOVE BEFORE FULLY ASSEMBLING ALL

COMPONENTS. BURNING YOUR STOVE WITHOUT A PEDESTAL OR LEG

KIT ATTACHED WILL VOID YOUR WARRANTY AND COULD PRESENT A

SAFETY HAZARD.