WARNING! DO NOT ATTEMPT TO OPERATE THIS WOODSTOVE

WITHOUT READING AND UNDERSTANDING THESE OPERAT-

ING INSTRUCTIONS THOROUGHLY. FAILURE TO OPERATE

THIS APPLIANCE PROPERLY MAY CAUSE A HOUSE FIRE.

LISTINGS & SAFETY CAUTIONS

These installation instructions describe the installation and

operation of the

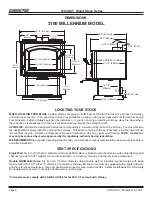

QUADRA-FIRE 3100

woodstove. This stove

meets the U.S. Environmental Protection Agency’s 1990

particulate emission standards. The 3100 is listed by OMNI-Test

Laboratories, Inc. to UL Safety Standard 1482, and ULC S627,

and (UM) 84-HUD. The 3100 is approved for mobile home

installations when not installed in a sleeping room and when an

outside combustion air inlet is provided. The structural integrity

of the mobile home floor, ceiling, and walls must be maintained.

The stove must be properly grounded to the frame of the

mobile home and use only listed double-wall connector pipe.

Outside Air Kit, Part 831-1780, must be installed in a mobile

home installation.

Check with your local building code agency before you begin

your installation to ensure compliance with local codes, including

the need for permits and follow-up inspections. Be sure local

building codes do not supersede UL specifications and always

obtain a building permit so that insurance protection benefits

cannot be unexpectedly cancelled. If any assistance is required

during installation, please contact your local dealer.

Inspect and clean vent system frequently in accordance with the

instructions contained in this manual. Do not connect this unit

to a chimney serving another appliance.

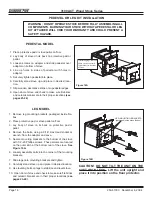

When using optional Blower, Part 831-1701, route power cord

away from unit. Do not route cord under or in front of appliance.

Do not elevate fire. Build wood fire directly on firebrick.

Do not overfire - if heater or chimney connector glows, you are

overfiring. Stove thermometer recommended.

Operate only with the door closed. Open only to add fuel to

the fire. Operating with the door open can cause hot embers or

sparks to fall out and a fire may result.

INSTALLATION MATERIALS NEEDED FOR SAFETY

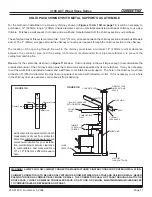

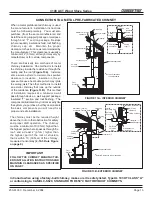

CHIMNEY CONNECTOR

(also known as flue pipe or stove

pipe): The chimney connector joins the stove to the chimney

(

see page 10

). It must be 6” (152mm) minimum diameter 24

MSG black or blued steel, or an approved air-insulated double

wall venting pipe.

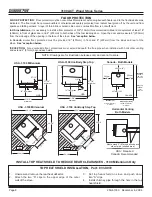

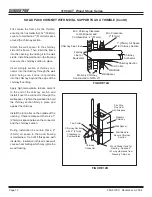

THIMBLE

: A manufactured or site-constructed device installed in

combustible walls through which the chimney connector passes

to the chimney

(see pages 11- 12)

. It is intended to keep the

walls from igniting.

CHIMNEY SYSTEMS

:

A. APPROVED MASONRY

(see specifications on page

10)

with at least 5/8” (16mm) fire clay lining joined with

refractory cement or other listed system suitable for use

with wood stoves.

B. PREFABRICATED 6" (152mm) listed high temperature (UL

103 HT or ULC S629M) chimney. Components required by

manufacturers for installation such as the chimney support

base, firestop (as appropriate), attic insulation shield,

insulated tee, etc., are necessary to assure a safe chimney

installation. Use only components manufactured for the

chimney. Chimney installation should meet NFPA 211

standards.

FIRE SAFETY

: To provide reasonable fire safety, the following should

be given serious consideration:

1. Install at least one smoke detector on each floor of your home

to ensure your safety. They should be located away from the

heating appliance and close to the sleeping areas. Follow

the smoke detector manufacturer’s placement and installation

instructions, and be sure to maintain regularly.

2. A conveniently located Class A fire extinguisher to contend with

small fires resulting from burning embers.

3. A practiced evacuation plan, consisting of at least two escape

routes.

4. A plan to deal with a chimney fire as follows:

In the event of a chimney fire:

A. Notify fire department

B. Prepare occupants for immediate evacuation.

C. Close all openings into the stove.

D. While awaiting fire department, watch for ignition of

adjacent combustibles from overheated stove pipe, hot

embers or sparks from the chimney.

VENTING SYSTEM

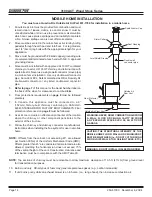

The venting system consists of a chimney connector and a chimney.

These get extremely hot during use. Temperatures inside the

chimney may exceed 2000

°

F (1100

°

C) in the event of a creosote

fire. To protect against the possibility of a house fire, the chimney

connector and chimney must be properly installed and maintained.

An approved thimble must be used when a connection is made

through a combustible wall to a chimney. A chimney support package

must be used when a connection is made through the ceiling

to a prefabricated chimney. These accessories are absolutely

necessary to provide safe clearances to combustible wall and ceiling

material. Follow venting manufacturer’s clearances when installing

venting system.

This stove may be connected to a lined masonry chimney or a listed

high temperature prefabricated approved metal chimney. Do not

connect it to a chimney serving another appliance. To do so will

affect the safe operation of both appliances.

WARNING!

NEVER DRAW

OUTSIDE

COMBUSTION AIR FROM A

WALL, FLOOR OR CEILING CAVITY OR FROM ANY ENCLOSED

SPACE SUCH AS AN ATTIC OR GARAGE.

WARNING! THIS APPLIANCE IS HOT WHILE IN OPERATION

AND MAY REMAIN SO UP TO 40 MINUTES OR LONGER AFTER

THERE IS NO FUEL IN THE FIREBOX. IF THIS APPLIANCE IS

IN A HIGH TRAFFIC AREA OR CHILDREN MAY BE NEAR IT IS

RECOMMENDED THAT YOU PURCHASE A DECORATIVE BAR-

RIOR TO GO IN FRONT OF THE APPLIANCE. ALWAYS KEEP

CHILDREN AWAY WHILE IT IS OPERATING AND DO NOT LET

ANYONE OPERATE THIS APPLIANCE UNLESS THEY ARE

FAMILIAR WITH THESE OPERATION INSTRUCTIONS.

3100 ACT Wood Stove Series

Page 4

250-6103C December 6, 2004

R