November 13, 2013

7021-130D

Page 23

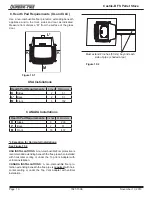

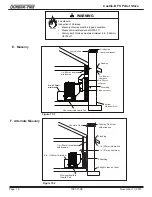

Castile-B FS Pellet Stove

High

Med

Low

Heat Output Switch

Reset Button

Reset

Button

C. Before Your First Fire

1. First, make sure your appliance has been properly

installed and that all safety requirements have been met.

Pay particular attention to the fire protection, venting and

thermostat installation instructions.

2. Double check that the ash drawer and firebox are

empty!

3. Check the position of the thermocouple, located above

the firepot, and make sure that it protrudes approximately

3/4 inch (19mm) into the firepot.

4. Close the front door.

IMPORTANT DETAIL: The tip of the thermocouple must

be in contact with the inside end of the thermocouple

cover or missed ignitions can occur.

D. Starting Your First Fire

1. A thermostat is required for proper operation of this

appliance, except for corn. At this time, fill the hopper

with pellets, set the thermostat to its lowest setting. Plug

the power cord into nearby outlet.

2. The exhaust blower will stay on for approximately 18

minutes even though the thermostat is not calling for heat.

This is normal.

3. L

ocate the heat output control switch mounted on the

back of the appliance in the upper right corner.

Figure

23.1.

Turn it to the “high” setting by pushing the top of

the control switch in and then adjust the thermostat to its

highest setting. Remove the right side panel and the red

call light located to the left of the control box will be on.

Figure 24.1 on page 24.

This indicates the thermostat is

calling for heat.

4. The fuel feed system and the igniter should now be on.

5. For your first fire it will be necessary to press the reset

button once approximately 2 minutes after start up and

again in 5 minutes. This will fill the feed system and allow

the appliance to begin dropping pellets. The appliance

will continue to run as long as the thermostat is calling for

heat.

6. Once the appliance has ignited, let it burn for approximately

15 minutes, then set the thermostat to the desired room

temperature. Adjust the heat output control switch to the

desired setting.

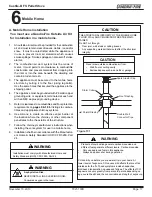

B. General Operating Information

1. Thermostat Calls For Heat

The appliance is like most modern furnaces; when the

thermostat calls for heat, your appliance will

automatically

light and deliver heat. When the room is up to temperature

and the thermostat is satisfied, the red call light will go off

and the appliance will shut down.

2. Heat Output Controls

This appliance is equipped with a heat output control

switch that has three settings or burn rates; low, medium

and high. The appliance will turn on and off as the

thermostat demands. When the thermostat calls for heat,

the appliance will start up at the burn rate for which it is

set. If the appliance is set at one of the lower settings, it

will run quieter but take longer to heat up an area than if it

were set at a higher burn rate. Regardless of the burn rate,

when the area is warm enough to satisfy the thermostat,

the appliance will shut off.

Figure 23.1

WARNING

Fire Hazard.

Keep combustible materials, gasoline

and other flammable vapors and liquids

clear of appliance.

• Do NOT store flammable materials in the appliance’s

vicinity.

• DO NOT USE GASOLINE, LANTERN FUEL, KEROSENE,

CHARCOAL LIGHTER FLUID OR SIMILAR LIQUIDS TO

START OR “FRESHEN UP” A FIRE IN THIS HEATER.

• DO NOT BURN GARBAGE OR FLAMMABLE FLUIDS

SUCH AS GASOLINE, NAPHTHA OR ENGINE OIL.

• DO NOT USE CHEMICALS OF FLUIDS TO START THE

FIRE.

• Keep all such liquids well away from the heater while it is in

use.

• Combustible materials may ignite.