November 13, 2013

7021-130D

Page 41

Castile-B FS Pellet Stove

Service Parts

R

Castile-FS-B

Beginning Manufacturing Date: Oct. 2009

Ending Manufacturing Date: Active

IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement

parts for your appliance please provide model number and serial number. All parts listed

in this manual may be ordered from an authorized dealer.

Stocked

at Depot

ITEM

DESCRIPTION

COMMENTS

PART NUMBER

1

Hopper Lid Assembly

Black

SRV7021-022MBK

Mahogany

SRV7021-022PMH

Sienna Bronze

SRV7021-022CSB

Willow

SRV7021-022CWL

Bumper, Rubber

Pkg of 12

SRV224-0340/12

Y

Magnet Round

SRV7000-140

Y

2

Top

Black

7021-101MBK

Mahogany

7021-101PMH

Sienna Bronze

7021-101CSB

Willow

7021-101CWL

3

Cast Retainer Upper

SRV7021-141

4

Convection Air Director

SRV7021-123

5

Hinge Bracket

SRV7021-115

6

Outer Skin Left

SRV7021-119

7

Brick, Left / Right, Cast

414-0270

8

Brick, Center, Cast

414-0260

9

Cast Retainer Lower Left Assembly

SRV7021-018

10.1

Pull Rod Assembly

SRV7021-005

Knob, Ash Dump Control Rod

832-3020

Spring, Firepot

200-2050

10.2

Wing Thumb Screw 8-32 x 1/2

Pkg of 24

7000-223/24

Y

10.3

Heating Element Assembly 18” (Loop Igniter)

Pkg of 10

SRV7000-462/10

Y

10.4

Firepot Assembly

SRV414-5200

Y

Bushing, Firepot

410-8320

Y

Floor, Firepot

414-0290

Y

Gasket, Firepot

240-0930

Y

Nut, Lock 1/4-20

Pkg of 25

226-0090/25

Y

Bolt, Firepot, 1-1/4” Long

Pkg of 25

225-0120/25

Y

10.5

Thermocouple Cover

Pkg of 10

812-4920

Y

10.6

Thermocouple

812-4470

Y

10.7

Thermocouple Clamp

SRV7001-203

Y

Additional service part numbers appear on following page.

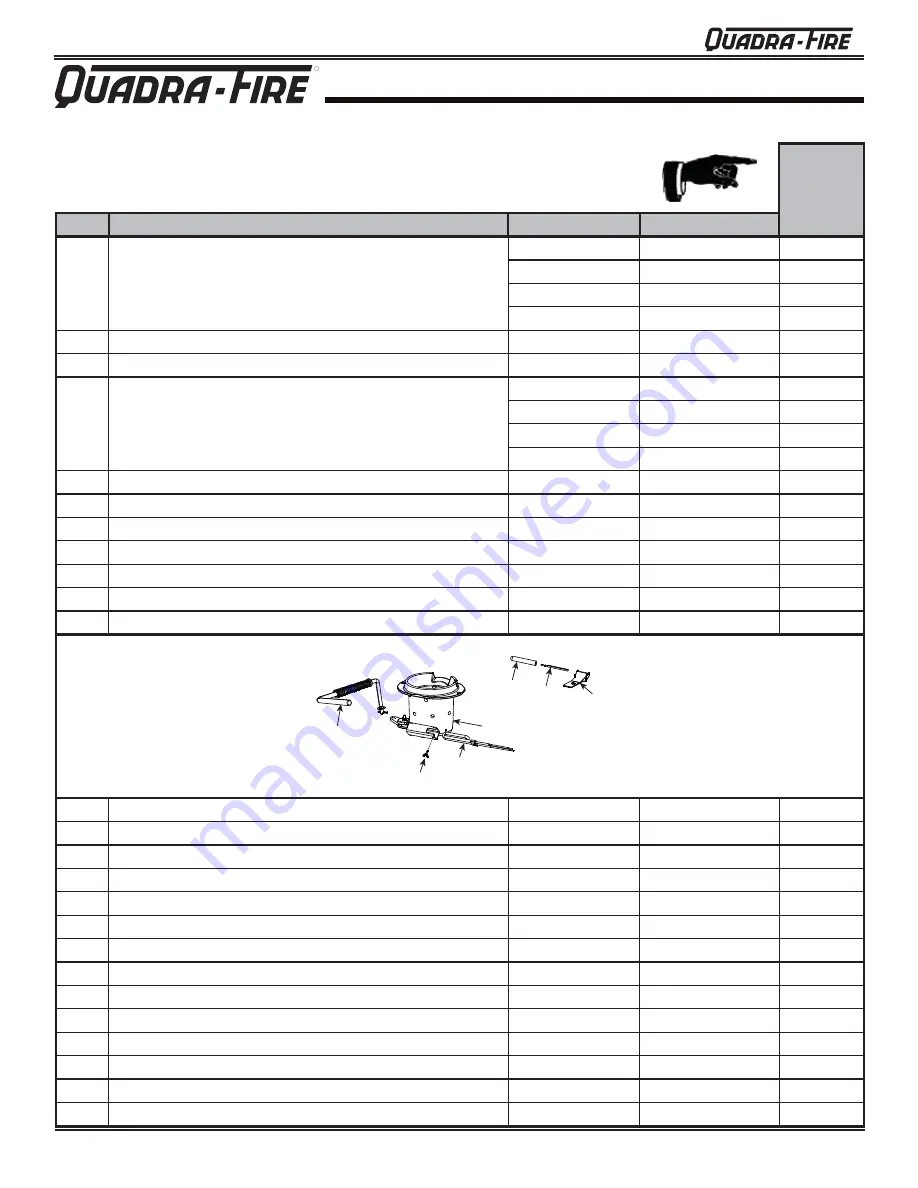

10.1

10 2

10.3

10.7

10.4

10.6

10.5

#10 Firepot Assembly and Asscociated Parts

D. Service Parts