6

7014-259B

November 30, 2017

CB1200 FREESTANDING

E. Mobile Home Approved

•

This appliance is approved for mobile home installa-

tions when not installed in a sleeping room and when

an outside combustion air inlet is provided.

•

The structural integrity of the mobile home floor, ceil

-

ing, and walls must be maintained.

•

The appliance must be properly grounded to the frame

of the mobile home and use only Listed pellet vent

Class “L” or “PL” connector pipe.

•

Outside Air Kit, part OAK-ACC must be installed in a

mobile home installation.

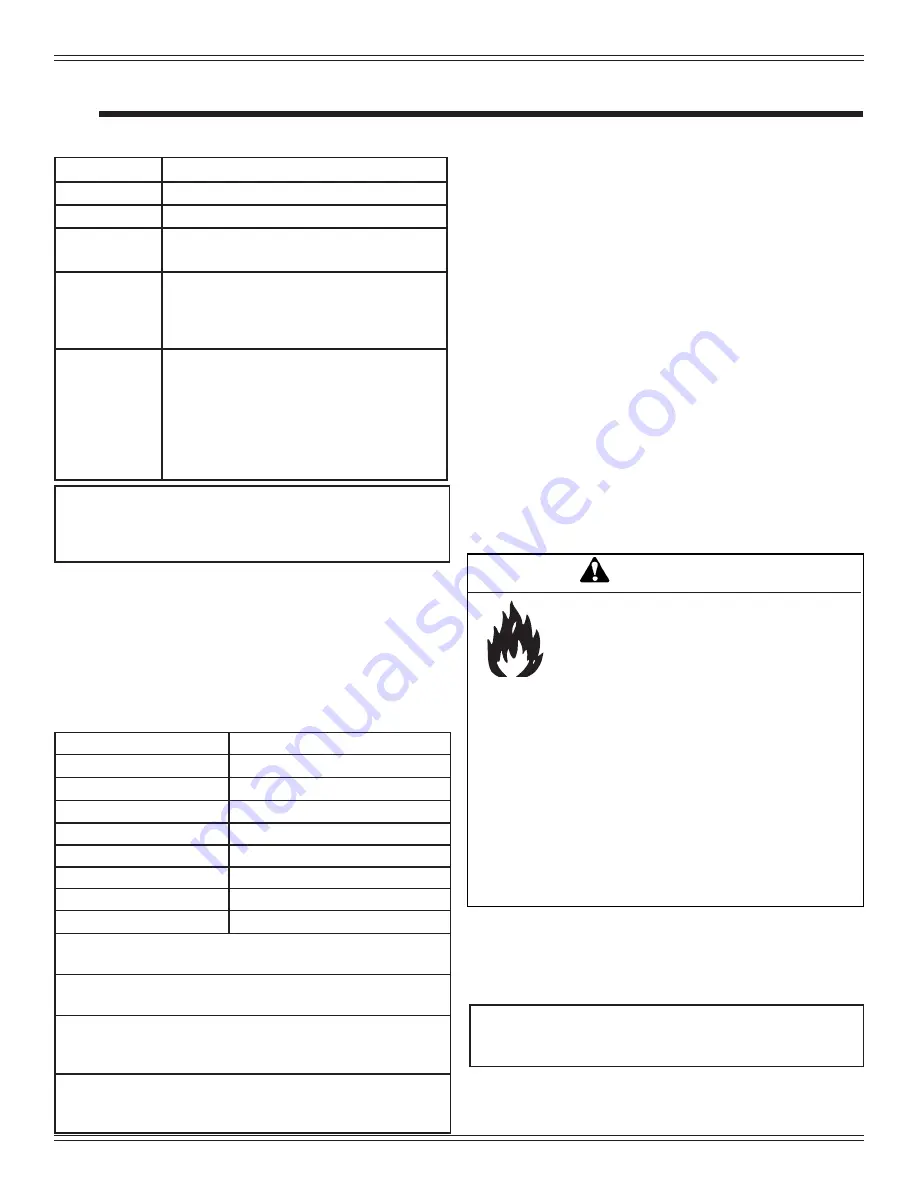

Model

CB1200 Pellet Appliance

Laboratory

OMNI Test Laboratories, Inc.

Report No.

061-S-21-4

Type

Solid Fuel Room Appliance/Pellet Fuel

Burning Type

Standard

ASTM E1509-04, ULC S627-00 and

ULC/ORD-C1482-M1990 Room Appli

-

ance Pellet Fuel Burning type and (UM)

84-HUD, Mobile Home Approved.

FCC

Complies with Part 15 of FCC Rules.

Operation is subject to the following

two conditions: (1) this device may not

cause harmful interference, and (2) this

device must accept any interference

received, including interference that may

cause undesired operation.

EPA Certification #:

955-14

EPA Certified Emissions:

1.1 grams per hour

*LHV Tested Efficiency:

76%

**HHV Tested Efficiency:

70.3%

***EPA BTU Output:

13,500 - 37,600 / hr

****BTU Input:

18,500 - 51,600 / hr

Vent Size:

3” or 4” L or PL

Hopper Capacity:

80 lbs.

Fuel:

Wood Pellets

*Weighted average LHV efficiency using data collected

during EPA emissions test.

**Weighted average HHV efficiency using data collected

during EPA emissions test.

***A range of BTU outputs based on EPA Default Effi

-

ciency and the burn rates from the low and high EPA

tests.

****Based on the maximum feed rate per hour multi-

plied by approximately 8600 BTU’s which is the average

BTU’s from a pound of pellets.

1

Listing and Code Approvals

A. Appliance Certification

NOTE: Hearth & Home Technologies, manufacturer of

this appliance, reserves the right to alter its products, their

specifications and/or price without notice.

NOTICE:

This installation must conform with local codes. In

the absence of local codes you must comply with the

ASTM

E1509-04, ULC S627-00, (UM) 84-HUD and ULC/ORD-

C-1482.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage.

For assistance or additional information, consult a qualified

installer, service agency or your dealer.

Quadra-Fire is a registered trademark of Hearth & Home

Technologies.

B. BTU & Efficiency Specifications

The Quadra-Fire Classic Bay 1200 Pellet Appliance meets

the U.S. Environmental Protection Agency’s emission limits

for pellet appliance sold after May 15, 2015.

This pellet appliance needs periodic inspection and repair for

proper operation. It is against federal regulations to operate

this pellet appliance in a manner inconsistent with operating

instructions in this manual.

• Installation and use of any damaged appliance.

• Modification of the appliance.

• Installation other than as instructed by Hearth & Home

Technologies.

• Installation and/or use of any component part not approved by

Hearth & Home Technologies.

• Operating appliance without fully assembling all components.

• Operating appliance without legs attached (if supplied with

appliance).

• Do NOT Over fire - If appliance or chimney connector glows,

you are over firing.

Any such action that may cause a fire hazard.

WARNING

Fire Risk.

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be voided by,

the following actions:

C. Glass Specifications

This appliance is equipped with 5mm ceramic glass.

Replace glass only with 5mm ceramic glass. Please con

-

tact your dealer for replacement glass.

D. Electrical Rating

115 VAC, 60 Hz, Start 5 Amps, Run 1.25 Amps