September 1, 2008

Page 43

Quadra-Fire · Castile Gas Stove · 7023-111E

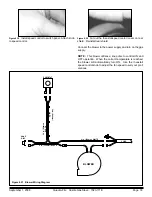

B. Vent Components Diagram

Figure 12.2 SL-D Series Vent Components

4 in. (102 mm) inner pipe 6-5/8 in. (168 mm) outer pipe

9-1/4 in.

(235mm)

6-1/2 in.

(165mm)

6-5/8 in.

(168mm)

17-24 in.

(432-610mm)

11-3/4 in.

(298mm)

5-3/4 in.

(146mm)

6-5/8 in.

(168mm)

6-3/8 in.

(162mm)

6-1/2 in.

(165mm)

9-5/8 in.

(244mm)

6-5/8 in.

(168mm)

6-1/2 in.

(165mm)

6-3/8 in.

(162mm)

9-5/8 in.

(244mm)

SLP6M

SLP12M

SLP12AM

SLP45-BK

SLP90M

3-3/4 in.

(95mm)

12-17 in.

(305-432mm)

35-3/4 in.

(908mm)

23-3/4 in.

(603mm)

47-3/4 in.

(1213mm)

SLP4M

SLP48M

SLP36M

SLP24M

SLP6AM