Page 27

VERTICAL TERMINATIONS (

CONT

.)

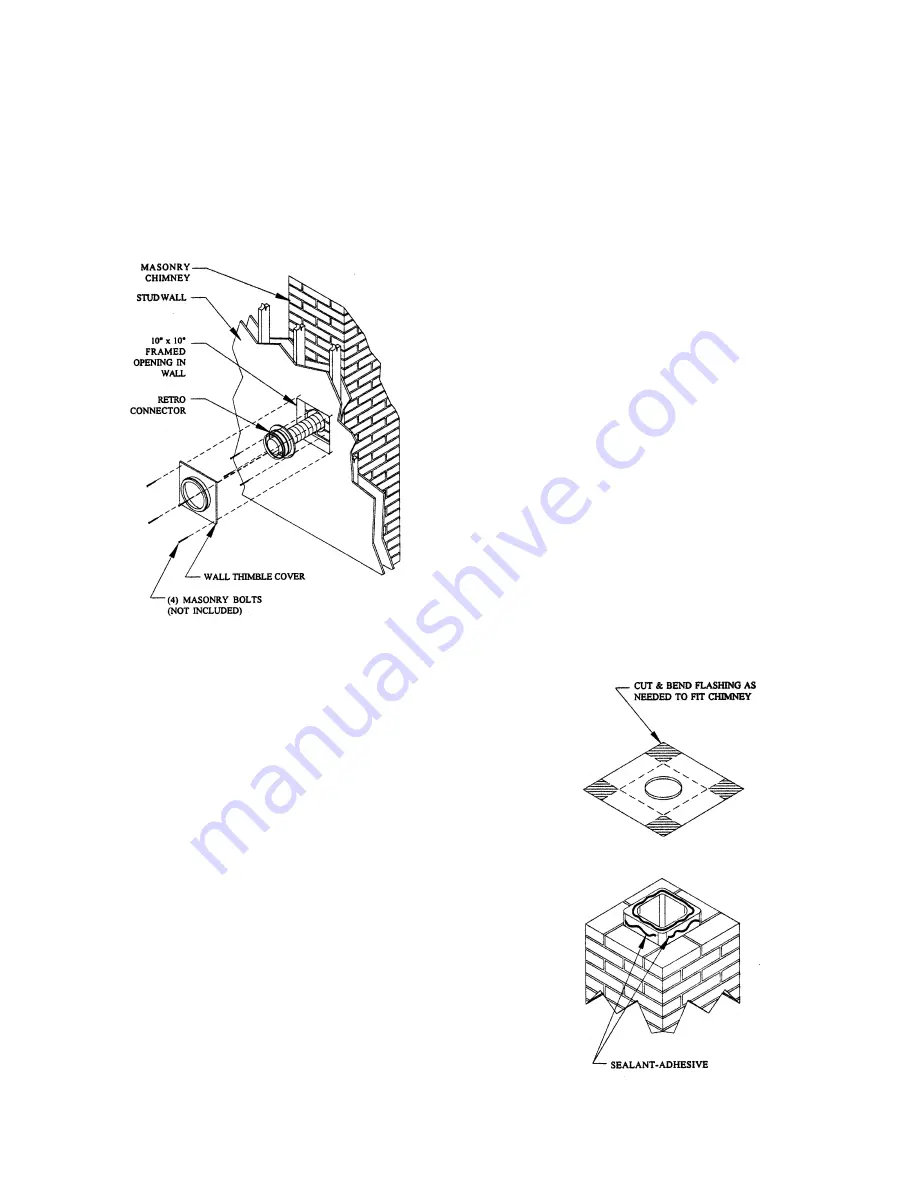

INSTALLATION INTO AN EXISTING MASONRY CHIMNEY

Step 1. Before cutting any holes, assemble the desired sections of direct vent pipe to determine the

center of the masonry penetration.

Step 3. Secure the flashing (SDV #705C) to the top

of the masonry chimney using a bead of

non-hardening sealant-adhesive. If the

flashing is larger than the top of the chimney,

cut and fold flashing as needed to fit

chimney (Figure 23).

Step 4. To determine the length of flex needed,

measure from 3” (76mm) above the top of

the flashing down to the level of the opening.

Add the distance from the center of the

chimney out through the wall. Cut a piece

of 4” (102mm) flex to this length (extended

to its nominal length). Be sure to leave 2”-

3” (51mm-76mm) of flex above the existing

chimney to allow for connection to the

termination kit.

FIG. 22

Step 2. Once the center point of the penetration has

been determined, cut a 6” (152mm)

diameter hole in the masonry. If the hole is

too large, the retro connector might not

mount properly; if the hole is too small, the

appliance might starve for intake air. If there

is a frame wall in front of the masonry wall,

cut and frame a 10” (254mm) square

opening in the wall (centered around the 6”

[152mm] masonry opening). If there is sheet

rock only (no studs) in front of the masonry

the 10” (254mm) opening is still needed, but

does not need to be framed. This allows the

retro connector to mount directly on the

masonry and provide the correct clearances

to combustibles (see Figure 22).

FIG. 23