Page 27

March 2000

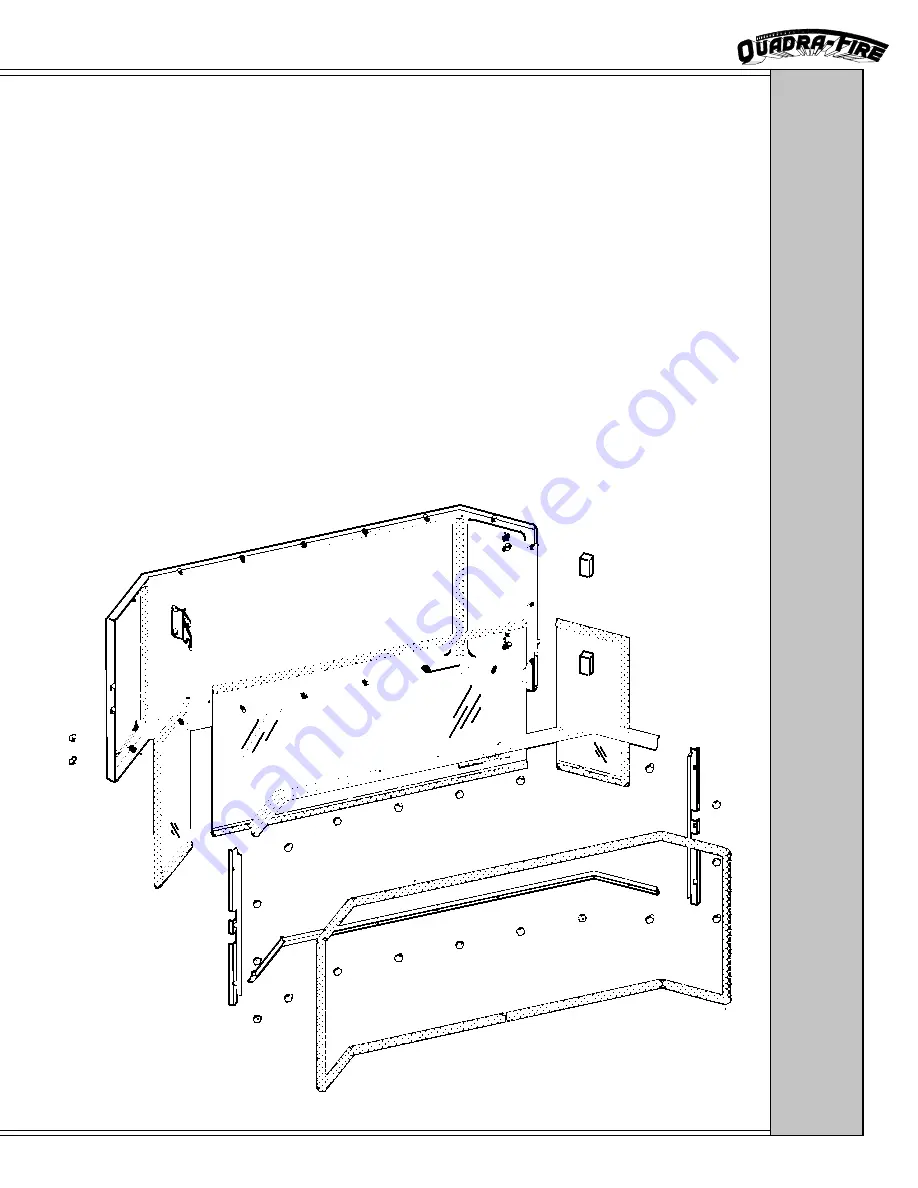

GB 40 I - FIREPLACE INSERT

MAINTENANCE

MAINTENANCE (cont.)

GLASS REPLACEMENT (posted doors only; full view doors must be returned to the manufac-

turer for glass replacement)

WARNING: USE ONLY MANUFACTURER-SUPPLIED REPLACEMENT PARTS

(PART NUMBER 842-1360 SIDE GLASS; 842-1280 CENTER GLASS).

1.

Use the supplied Allen wrench to open front. Lift door off hinges and place on a soft surface.

2.

Remove rope gasket from door frame.

3.

With a 5/16” wrench, remove all nuts that hold glass retaining bars in place. Remove retaining bars.

4.

Be very careful when lifting old glass out of the door frame.

5.

Insert new glass and reinstall in reverse order. Be sure to use new door gasket (part number 842-

1420, 5/8” x 96” rope).

NOTE: Be sure to clean glass and gold door before lighting insert.