May 2, 2014

7034-277B

9

MT. VERNON AE

4

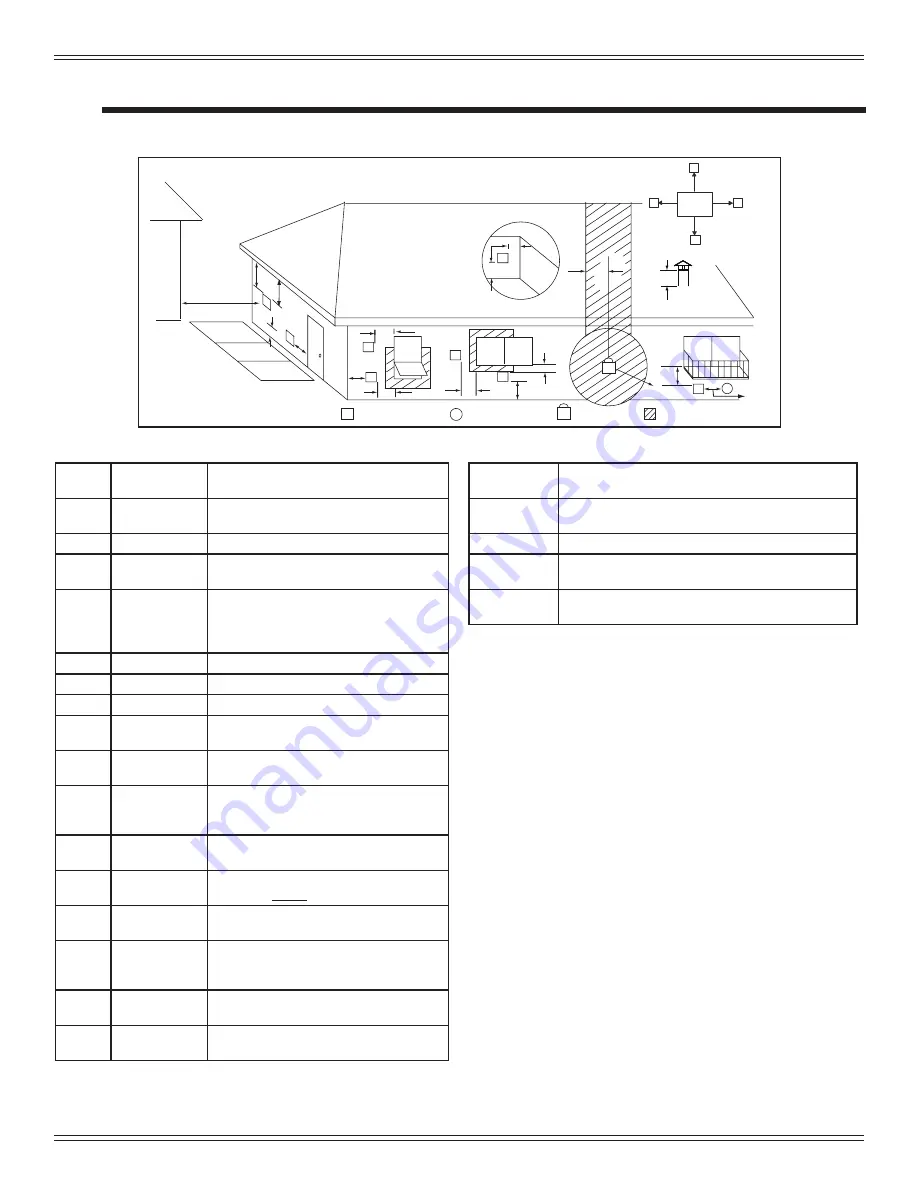

Vent Information

A. Venting Termination Minimum Requirements

J or K

X

V

M

I

H

A

V

G

B

V

V

A

B

V

F V

C

B

B

E

L

V

D

V

Electrical

Service

V

N

V

N

V

N

N

V

Inside Corner

FIXED

CLOSED

OPEN

OPEN

FIXED

CLOSED

V

X

G

G

Termination Cap

Air Supply Inlet

Gas Meter

Restricted Area

O

P

Figure 9.1

A

12 in.

Above Finish Grade (the grade surface

must be a non-combustible material

B

12 in.

48 in. no OAK

Open door or window: below or to the side

B

12 in.

Open door or window: above

C

6 in.

Permanently closed window: above, below

or to the side

D

18 in.

36 in. no OAK

Vertical clearance to a ventilated soffit

located above the terminal within a hori-

zontal distance of 2 ft from the center-line

of the terminal

E

12 in.

Clearance to unventilated soffit

F

12 in.

Clearance to outside corner

G

12 in.

Clearance to inside corner

H

36 in.

Above gas meter/regulator measured from

horizontal center-line of regulator

I

36 in. USA

72 in. Canada

Clearance to service regulator vent outlet

J

12 in.

48 in. no OAK

Clearance to non-mechanical air supply

inlet to the building or the combustions air

inlet to any other appliance

K

10 ft horizontal

3 ft vertical

Clearance to mechanical air supply

L

7 ft.

Above paved sidewalk, paved driveway

located on

public

property

M

12 in.

Under an open veranda, porch, deck or

balcony

N

See Note

below*

Electric service: above, below or to the

side (location must not obstruct or interfere

with access)

O

24 in.

Adjacent building, fences and protruding

parts of the structure

P

12 in.

Clearance above roof line for vertical

terminations

All minimum clearances are listed with an Outside Air Kit (OAK) installed, unless otherwise noted in table below.

24 in.

Above grass, top of plants, wood or any other com-

bustible

12 in.

36 in. no OAK

Clearance from any forced air intake of other appli-

ance

12 in.

Clearance horizontally from combustible wall

15 in.

Vented directly through a wall, minimum length of

horizontal pipe

6 in. horizontal

12 in. vertical

Minimum horizontal or vertical terminations must

protrude from wall

*NOTE:

Consult local building, fire officials or authorities having jurisdic-

tion. Local codes or regulations may require different clearances.

NOTICE:

Do NOT Terminate Vent:

•

In any location that will allow flue gases or soot from en-

tering or staining the building

• In any location which could create a nuisance or hazard

•

In any enclosed or semi-enclosed area such as a carport,

garage, attic, crawl space, under a sun deck or porch,

narrow walkway

• Closely fenced area, or any location that can build up

a concentration of fumes such as a stairwell, covered

breezeway, etc.

NOTICE:

Termination must exhaust above air inlet elevation.

• It is recommended that at least 60 inches (1.52m) of vertical

pipe be installed when appliance is vented directly through a

wall. This will create a natural draft, which will help prevent

the possibility of smoke or odor venting into the home during

a power outage.

• It will also keep exhaust from causing a nuisance or hazard

by exposing people or shrubs to high temperatures.

• The safest and preferred venting method is to extend the vent

vertically through the roof or above the roof.