October 28, 2014

7080-131D

21

MT VERNON E2

7

Mobile Home Installation

You must use a Quadra-Fire Outside Air Kit

for installation in a mobile home.

1.

An outside air inlet must be provided for the combustion

air and must remain clear of leaves, debris, ice and/or

snow. It must be unrestricted while the appliance is in

use to prevent room air starvation which causes smoke

spillage. Smoke spillage can also set off smoke alarms.

2.

The combustion air duct system must be made of metal.

It must permit zero clearance to combustible construc-

tion and prevent material from dropping into the inlet or

into the area beneath the dwelling and contain a rodent

screen.

3. The appliance must be secured to the mobile home

structure by bolting it to the fl oor (using lag bolts). Use

the same holes that secured the appliance to the shipping

pallet.

4.

The appliance must be grounded with #8 solid copper

grounding wire or equivalent, terminated at each end

with an NEC approved grounding device.

5.

Refer to Clearances to Combustibles and fl oor protection

requirements on

page 8

for listings to combustibles and

appropriate chimney systems.

6.

Use silicone to create an effective vapor barrier at the

location where the chimney or other component pene-

trates to the exterior of the structure.

7. Follow the chimney manufacturer’s instructions when

installing the vent system for use in a mobile home.

8.

Installation shall be in accordance with the Manufacturers

Home & Safety Standard (HUD) CFR 3280, Part 24.

Part Number: OAK-3

NEVER INSTALL IN A SLEEPING ROOM.

WARNING

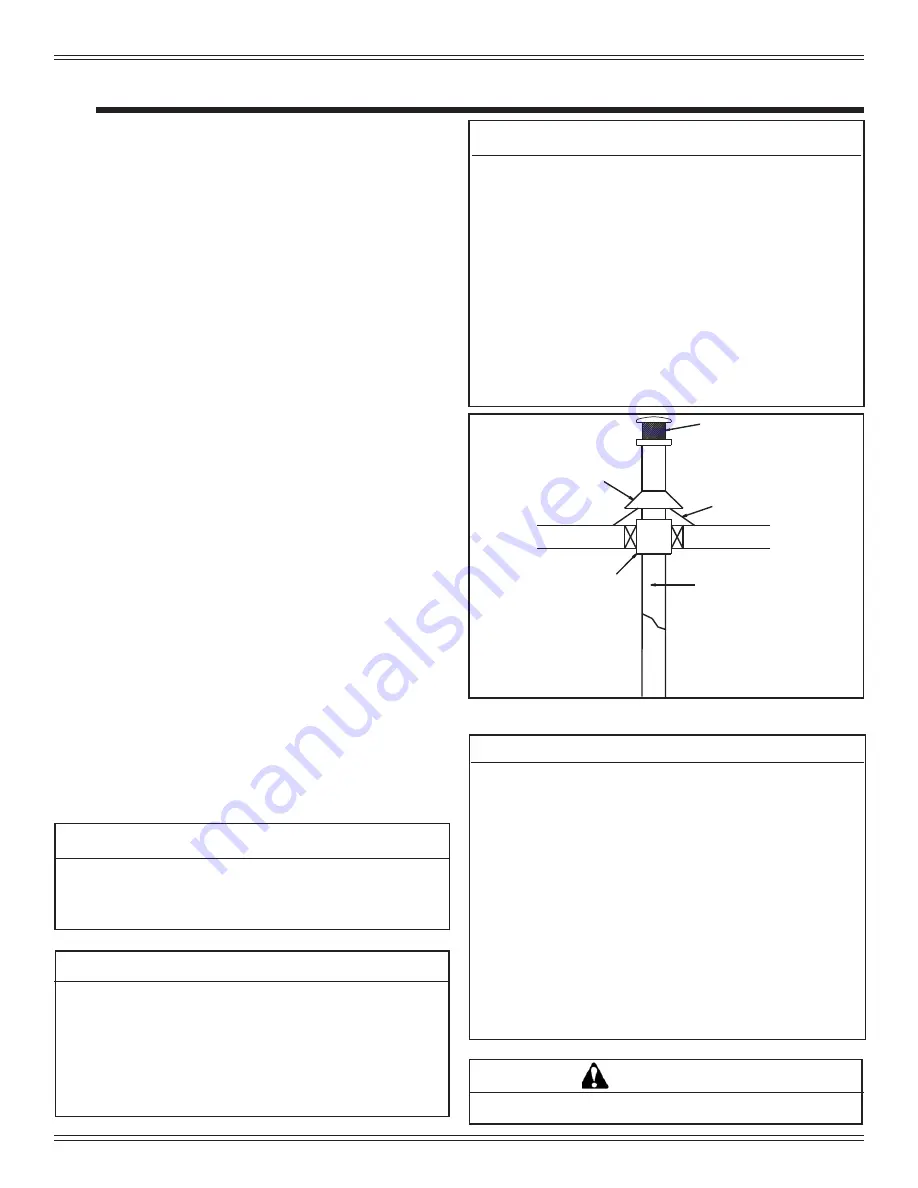

Spark Arrestor Cap

Roof Flashing

Storm Collar

Joist Shield/Firestop

Approved Class L

or PL Pellet Vent

Figure 21.1

CAUTION

Never draw outside combustion air from:

• Wall,

fl oor or ceiling cavity

• Enclosed space such as an attic or garage

CAUTION

THE STRUCTURAL INTEGRITY OF THE MOBILE

HOME FLOOR, WALL AND CEILING/ROOF MUST BE

MAINTAINED

Do NOT cut through:

• Floor joist, wall, studs or ceiling trusses.

• Any supporting material that would affect the structural

integrity.

This unit is to be connected to a factory-built chimney

conforming to CAN/ULC-S629, Standard for 650°C

Factory-Built Chimneys.

For removal of the chimney for mobile home transpor-

tation, contact the proper transportation offi cials.

WARNING

Products of combustion generate carbon monoxide

and different fuels generate different levels. Carbon

monoxide

•

Only use approved fuels in this appliance.

•

Always keep door shut during operation. Operating

this unit with doors open can allow CO to leak into the

home.

CO can kill you before you are aware it is in your home.

At lower levels of exposure, CO causes mild effects

that are often mistaken for the fl u. These symptoms

include headaches, dizziness, disorientation, nausea

and fatigue. The effects of CO exposure can vary greatly

from person to person depending on age, overall health

and the concentration and length of exposure.

WARNING

It is critical to have a working smoke detector

installed in the home of unit operation.

•

Smoke alarms that are properly installed and maintained

play a vital role in reducing fi re deaths and injuries.

Having a working smoke alarm reduces the chance of

fi re related injuries..