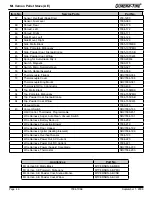

Page 42

7034-106E

September 1, 2008

R

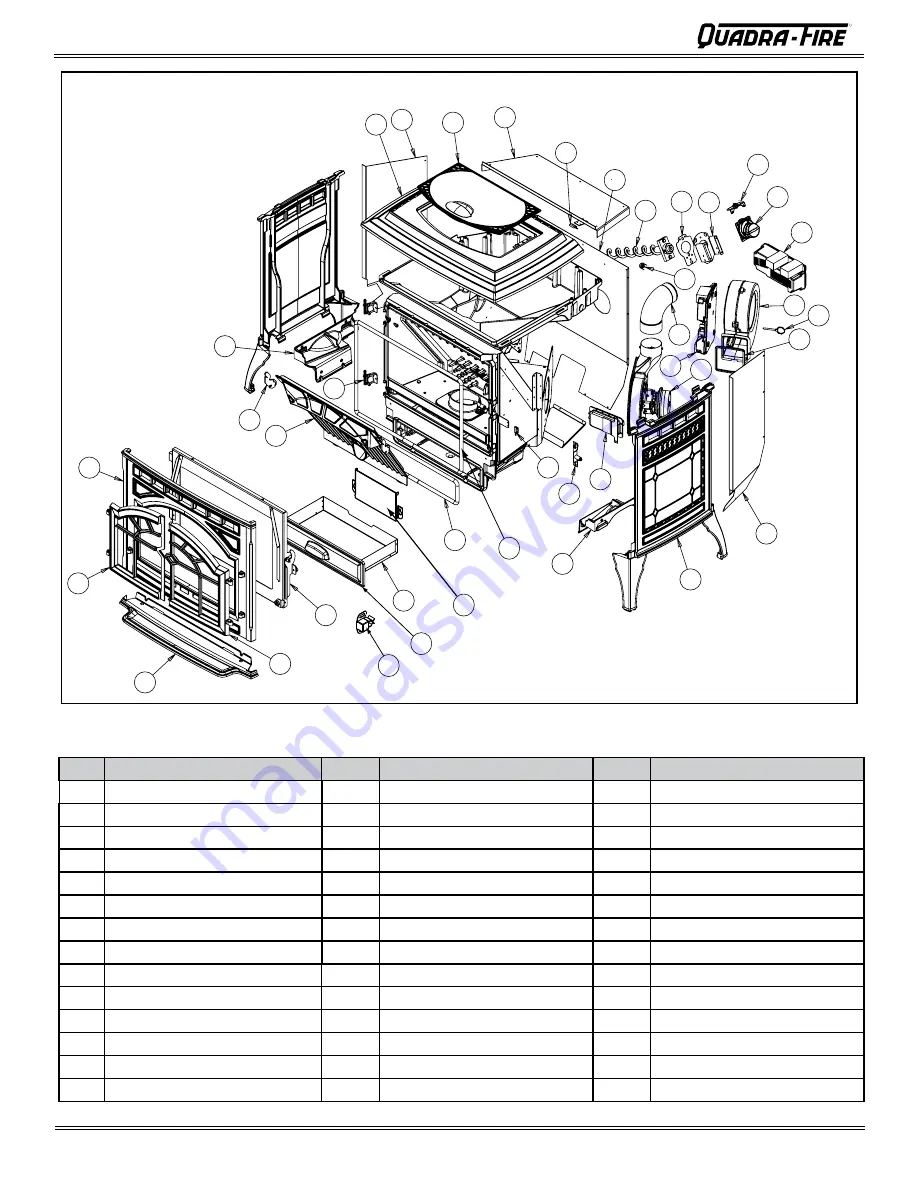

Mt. Vernon Pellet Stove (AE)

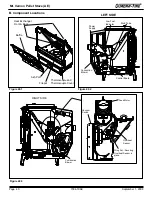

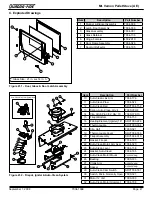

Figure 42.1

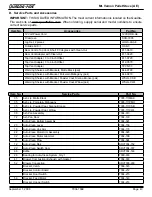

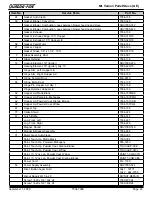

Item

Description

Item

Description

Item

Description

35

Ash Lip

49

Exhaust Transition

63

Shroud, Left

36

Door, Cast, Right

50

Gasket, Blower, Convection

64

Top, Cast

37

Door Assembly

51

Detent Pin 3/16

65

Side Mount, Left

38

Ash Pan Assembly

52

Blower, Convection

66

Hinge, Male, Door

39

Gasket, Ash Door

53

Power Supply

67

Latch, Baffle

40

Gasket, (Rope) Door

54

Feed Motor

68

Baffle

41

Switch, Magnetic

55

Switch, Optical Assembly

69

Front, Cast

42

Bracket, Latch

56

Bracket, Feed Motor

70

Door, Cast, Left

43

Vacuum Switch

57

Sensor, Overheat (Snap Disc)

71

Clip Receiver

44

Side Mount, Right

58

Gasket, Feed Motor

72

Ash Pan Door

45

Side, Cast. Left & Right

59

Feed Spring Assembly

73

Intake Shield

46

Shroud, Right

60

Shroud, Rear

47

Blower, Combustion (Exhaust)

61

Hopper Top

48

Control Board

62

Hopper Lid