Page 24

7063-173D

November 22, 2011

R

VOYAGEUR Wood Insert

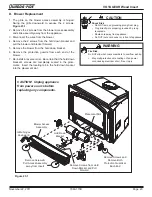

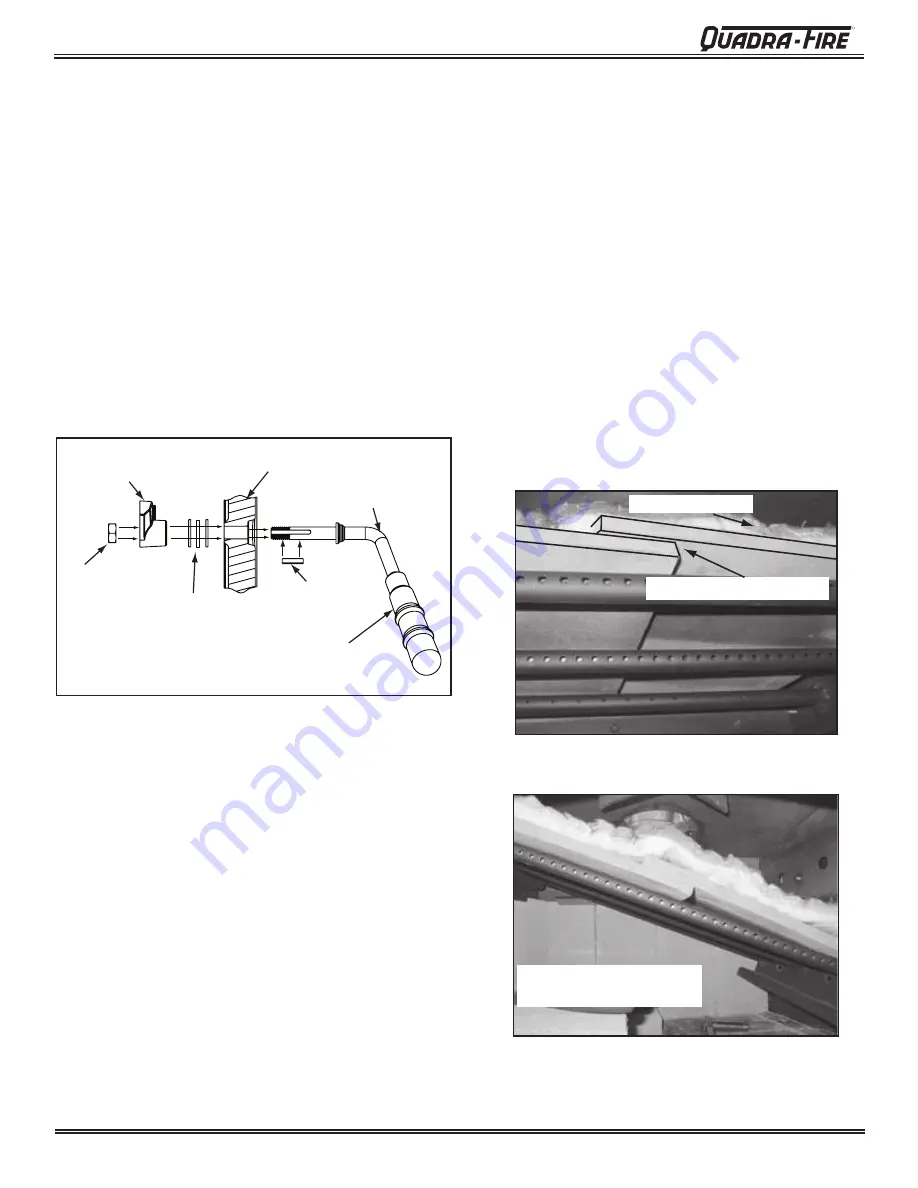

Figure 24.1

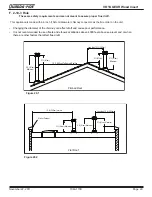

F. Baffl e & Ceramic Blanket Removal

1.

Remove all ash from the fi rebox, and extinguish all hot

embers before disposal into a metal container.

2. It is easier to remove both baffl e boards and ceramic

blanket after the tube channel assembly has been partially

disassembled and the right side lowered. Follow steps

1 through 4 on

page 25

for removal of the tube channel

assembly. It is not necessary to completely remove the

tube channel assembly.

3. Once the baffl e protection cover has been removed, pull

the baffl e boards and ceramic blanket forward about 1 inch

(25mm) and then overlap the baffl es about 1-2 inches (25-

51mm).

Figure 24.2

.

4. Slide the tube channel assembly to the left as far as it will

go and lower the right side. Remove the baffl e boards and

ceramic blanket together.

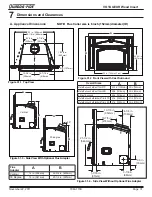

Figure 24.3

.

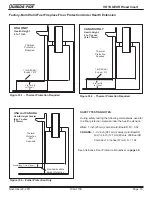

4. Re-install in reverse order. Be sure the baffl e boards and

ceramic blanket are in their proper positions.

See Figure

12 .1 on page 12.

E. Door Handle Assembly

1. Install washer on door handle shaft.

2. Slide door handle through door.

3. Install additional washer(s) as shown in

Figure 24.1.

4. Install key in groove.

5. Align groove in latch cam with key; slide latch cam over

shaft

6. Install locknut but do not overtighten, the handle needs

to move smoothly.

7. Install handle turning in a counter-clockwise motion to

desired location on door handle rod.

Figure 24.1.

CAUTION!

Do not overtighten lock nut. The door handle

needs to move smoothly.

Locknut

Latch Cam

Spacing

Washers

Door Cross

Section

Square Key

Door Handle Shaft

Fiber Handle

Figure 24.2

Figure 24.3

Slide Tube Channel to the

Left and Lower Right Side

Baffle Boards Overlapping

Ceramic Blanket