Quadra-Fire • QV36DC-A • 2161-900 Rev. B • 10/08

22

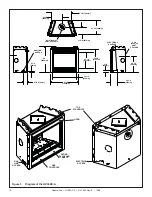

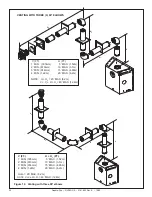

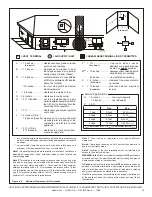

Figure 19.

HEAT

SHIELD

3” MIN.

(76 mm)

COMBUSTIBLE

SURFACE

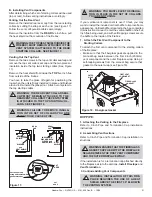

To Install the Heat Shield:

1. Determine if the heat shield is required. Do so by mea-

suring the vertical distance between the top horizontal

surface of the elbow to any combustible surface above.

If the distance is more than 4 inches, the heat shield is

NOT

required. If it is 4 inches or less, the heat shield

IS

REQUIRED

. Install per the following steps. See Figure

19.

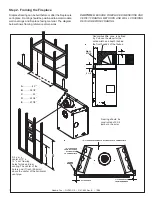

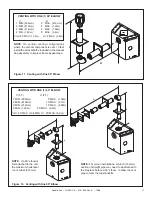

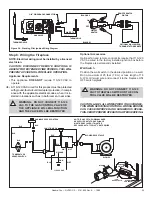

COMBUSTIBLE SURFACE

DIRECTION

UP

HEAT SHIELD

90

°

ELBOW

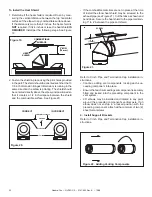

Figure 20.

CORRECT

INCORRECT

2. Fasten the shield in place using the pilot holes provided

in the part. The shield should be oriented such that the 13

1/8 inch dimension (longest dimension) is running in the

same direction the elbow is pointing. The shield should

be centered directly above the elbow, and positioned so

that it creates a 1/2 inch airspace between the shield

and the combustible surface. See Figure 20.

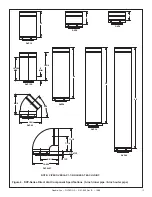

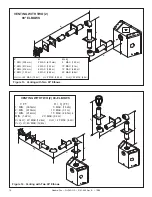

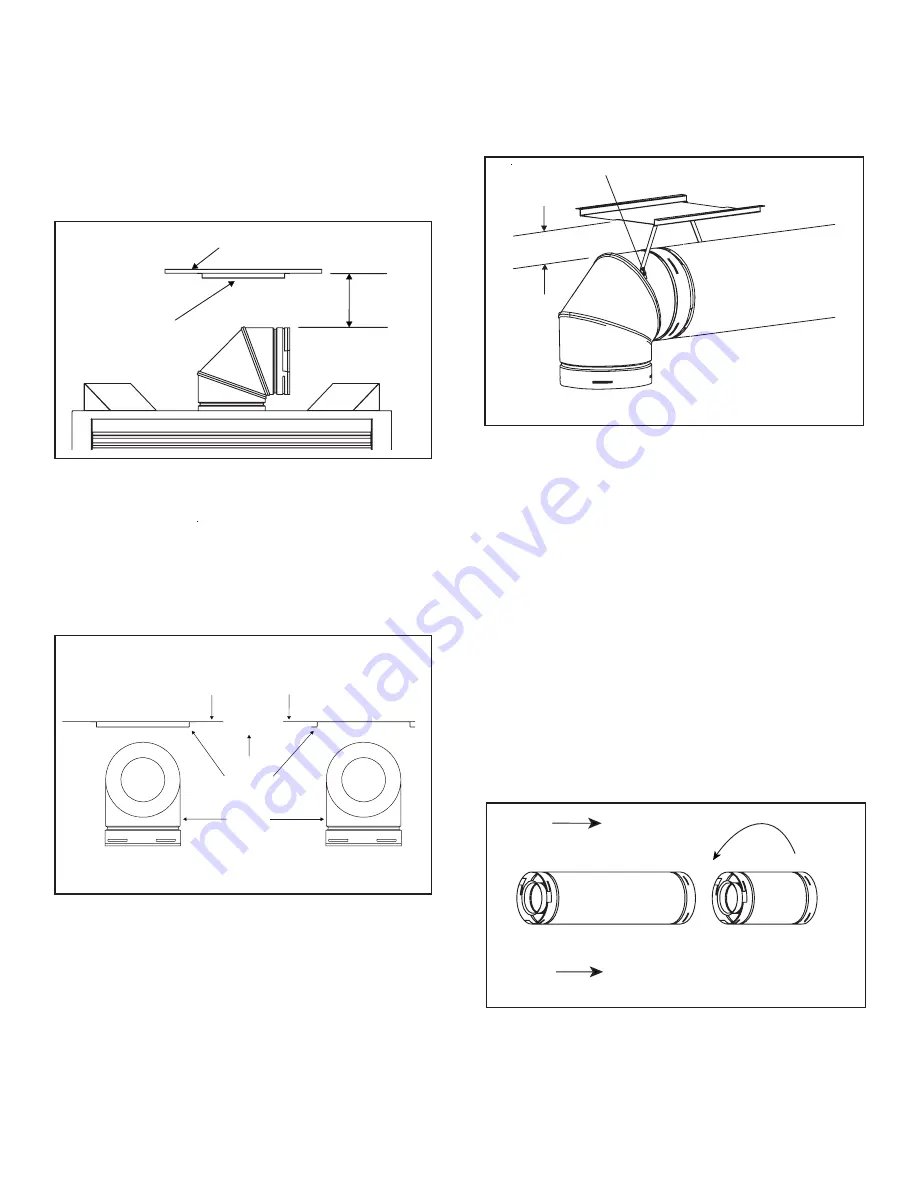

Figure 22. Adding Venting Components

Refer to Cinch Pipe and Termination Cap installation in-

structions.

• Continue adding vent components, locking each suc-

ceeding component into place.

• Ensure that each succeeding vent component is securely

fi tted and locked into the preceding component in the

vent system.

• 90° elbows may be installed and rotated to any point

around the preceding component’s vertical axis. If an

elbow does not end up in a locked position with the

preceding component, attach with a minimum of two (2)

sheet metal screws.

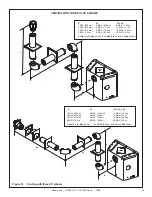

4. Install Support Brackets

Refer to Cinch Pipe and Termination Cap installation in-

structions.

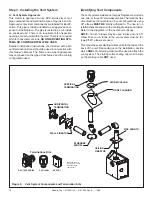

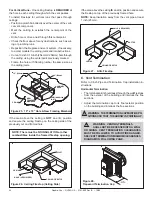

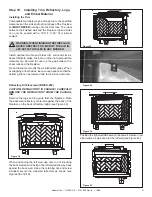

• If the combustible materials are not in place at the time

of install the elbow heat shield may be screwed to the

exhaust pipe (see Figure 21). Cut the tabs as shown and

bend down. Secure the heat shield to the pipe maintain-

ing 3” to 4” between the pipe and shield.

3 in.

(76mm)

SCREW

Figure 21.

Summary of Contents for QV36DC-A

Page 39: ......